Non Destructive Testing(NDT) Services

Welder Qualification & Welding Procedure Specification (WPS)

Where you have a requirement for independent verification that welding has been performed to the required specification. Our welding professional provide welder qualifications and procedure qualification.

Certifying welder qualifications – Welder Performance Qualification:

A welder must hold the necessary qualifications to carry out welding. AQC welding specialists will certify the welder to an approved weld procedure by monitoring and assessing the welder during the welding process, and submitting the test piece to the lab for the relevant testing required by the applicable code. The certification of a welder is usually valid for two or three years, after which there would be a requirement for re-certification of their Welder Performance Qualification. We are the Non destructive testing services providers.

By using AQC third party witnessing services, you have Total Quality Assurance that your welding procedures and welders are in accordance with statutory legislation and internationally-recognised welding codes; we qualify and certify welding procedures to BS EN ISO 15614 and ASME IX, and welders in accordance with BS EN 287, BS EN IS0 9606, BS 4872 and ASME IX.

Certifying welding procedures – Welder Procedure Specification and Welder Procedure Qualification Record:

Many manufacturers need independent approval for their welding procedures – either for compliance with international standards and codes or to comply with project requirements. Our welding specialists understand the codes or standards that are applicable to verify welding procedures and, as part of the third party witnessing process, we can:

- Create a Welder Procedure Specification (WPS) – a ‘technique’ card that documents how to produce a weld.

- Carry out non-destructive testing and destructive testing on the weld test piece produced under the WPS in our laboratories.

- Verify the weld test piece meets the applicable codes or standards

- Issue a Welder Procedure Qualification Record (WPQR) for the weld procedure, which qualifies the WPS

Ultrasonic Testing (UT)

Ultrasonic testing is a form of non-destructive testing that is typically used to detect volumetric flaws, material integrity and component thickness.

This common form of ultrasonic testing is used to carry out inspection on castings, forgings, welded components and composite structures in all industry sectors.

The method can be performed on all types of materials and its applications include:

- Flaw detection such as inclusions, cracks and porosity – particularly for small flaws or flaws situated deep within a part

- Determining the thickness of test objects, particularly in erosion or corrosion monitoring

- Assessment of bond integrity

The benefits of this method include quick accurate inspection and portable operation.

AQC uses advanced ultrasonic equipment and we can inspect customers’ components and structures to industry codes, standards or customer specifications, ensuring that your components and structures meet the highest standards for safety and reliability. We offer both laboratory and on-site manual ultrasonic testing.

The technique uses a pluser/receiver unit to power an ultrasonic transducer. The transducer is placed into contact with the tested object and pulsed sound waves are generated into the object. The reflected waves are received by the transducer and the signals are shown on the display unit. Skilled interpretation of the signals will indicate if there are any flaws or imperfections.

Ultrasonic Thickness Testing (UTT)

Applied Technical Services offers ultrasonic thickness testing (UTT) to determine material thickness and to measure the thickness of coatings and/or linings. Our technicians have been trained to calibrate the UTT gauges based on materials.

Our certified staff of NDT technicians provide quality inspection services for a broad range of industry sectors throughout the US and abroad. Ultrasonic thickness testing (UTT) services are offered in our laboratories, field locations and/or on customer premises.

Radiography Testing – Gamma radiography IR-192, CO-60 (RT)

Radiographic testing is one of the most widely used techniques of volumetric non-destructive testing and is often used to reveal internal, surface and sub-surface irregularities.

Radiographic testing is widely used in a variety of industry sectors including aerospace, power generation, construction, petroleum, chemical and automotive, and for all types of components and parts. The technique is commonly used on welded parts, castings, forgings, composites and is also used for corrosion mapping and the measurement of wall thickness.

Digital Radiography Testing- X ray (DRT)

Digital radiography is becoming more widely used for detecting defects, cracks, corrosion, erosion and loss of wall thickness.

Digital radiography is used in all industry sectors and, in particular, for assessing piping, pressure vessels and valves. The technique can detect discontinuities in a range of materials including aluminium, steel, plastics and composites.

The method is similar to conventional radiography, but images are not captured on film. Instead, images are captured using either flat panel detectors or phosphor-coated imaging plates. AQC uses two types of digital radiography:

- Computed Radiography (CR): Uses reusable phosphor-coated imaging plates to capture images.

- Digital Radiography (DR): Uses flat panel detectors to capture images.

Digital radiography has several important benefits as images can be enhanced and magnified for viewing and interpretation of findings.

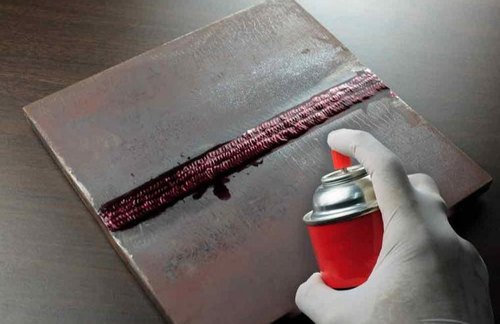

Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection (MPI) is a non-destructive testing method that can detect surface and subsurface flaws in ferromagnetic materials.

Magnetic particle inspection is often carried out to help determine an item’s fitness for use or conformity. This quick and relatively easy to apply technique is widely used in all industry sectors including aerospace, automotive, petrochemical, structural steel,and power generation to inspect a variety of products and equipment such as engine, suspension and braking system components, castings, forgings and weldments. Magnetic particle inspection is often carried out to help determine an item’s fitness for use or conformity.

Our techniques for magnetic particle inspection include:

- Bench (Direct current/Head shot/Central Conductor/AC/HWDC)

- Permanent magnetic

- Yoke (AC/HWDC)

- Ring bench

- Coil/cable wrap technique

- Prod technique

The technique works by inducing a magnetic field in the component tested. If a surface or near-surface flaw is present, the magnetic flux is distorted and ‘leaks’ around the flaw. By dusting the surface of the tested item with fine magnetic particles such as ferrous iron filings, (applied either dry or suspended in liquid), the particles will be attracted to the area of the flux leakage creating a visible indication of the defect. The indication can be evaluated by the operator to determine what it is, what may have caused it, and what action should be taken, if any.

Liquid Penetrant Inspection (LPI)

Liquid Penetrant Inspection (LPI) is widely used to detect surface breaking flaws.

Liquid penetrant inspection (LPI), is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities. Dye penetrant inspection can be applied to both ferrous and non-ferrous materials and all non-porous materials (metals, plastics or ceramics).

It is commonly used to detect defects in castings, forgings and weldments. AQC works with all industry sectors including aerospace, power generation, petrochemical and oil and gas, and we can provide dye penetrant inspection on-site at our customer’s premises or at our accredited laboratories.

Painting Inspections

- Humidity & Dew Point temperature check

- Salt contamination check

- Dust level check

- Surface Roughness recording

- Wet film thickness check

- Dry film thickness check

- Cross hatch test, adhesion testing

- Visual Inspection

- Pull– off adhesion test

- Cross hatch test

- Holiday test & visual

- Paint applicator assessment & Procedure qualification

Project Expediting

Expediting is a real-time task, which often demands pro-active responses to situations as they occur. In many cases it’s impossible to be on-site with every supplier around the world, so there is a need for trusted local expeditors with in-depth knowledge of procurement, production and delivery processes.

Large-scale projects and the supply of critical goods and equipment can involve complex international supply chains, with items procured from suppliers in multiple countries. Late delivery from any one supplier can have an impact on the whole chain, preventing projects from being completed on time and on budget. Expediting means taking any action necessary to ensure that deliveries are made on time and to specification.