The following should be considered when selecting equipment for magnetic particle testing.

- Is equipment for wet or dry method?

- Magnetization requirements (AC or DC)

- Demagnetization- incorporated or separate unit?

- Ampere required.

- Line voltage requirements.

- Accessories needed or required.

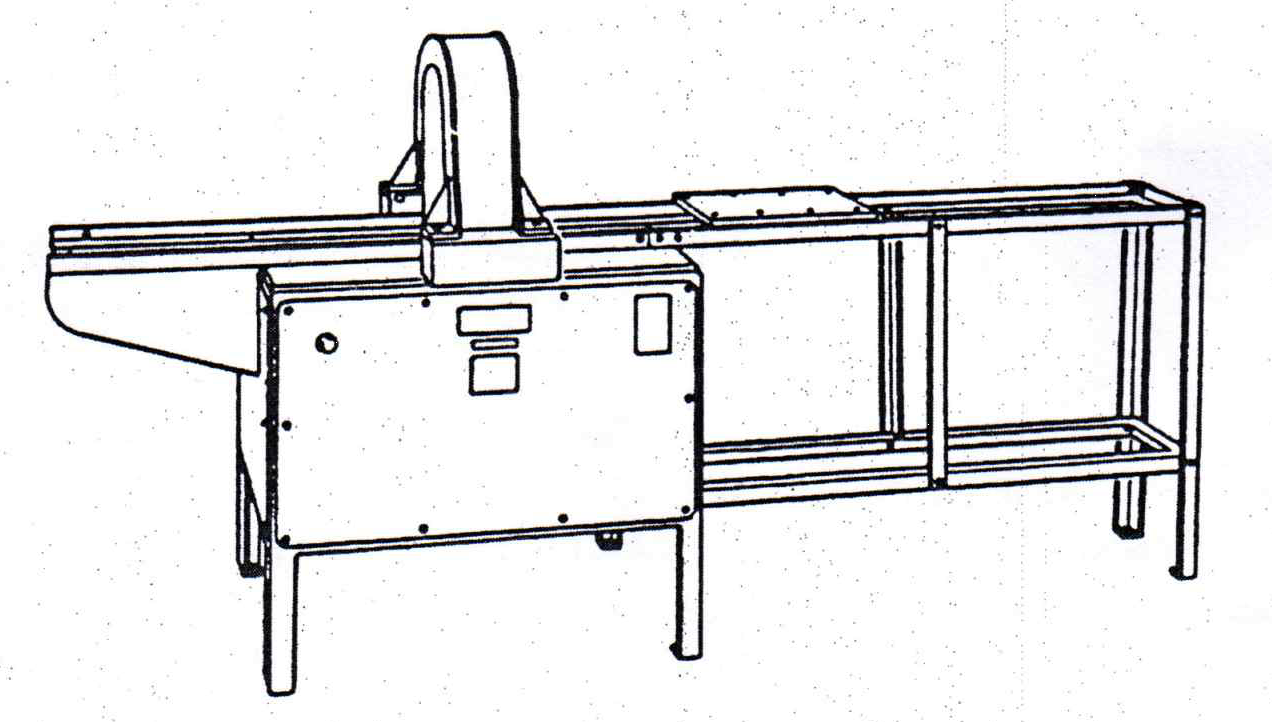

WET HORIZONTAL EQUIPMENT

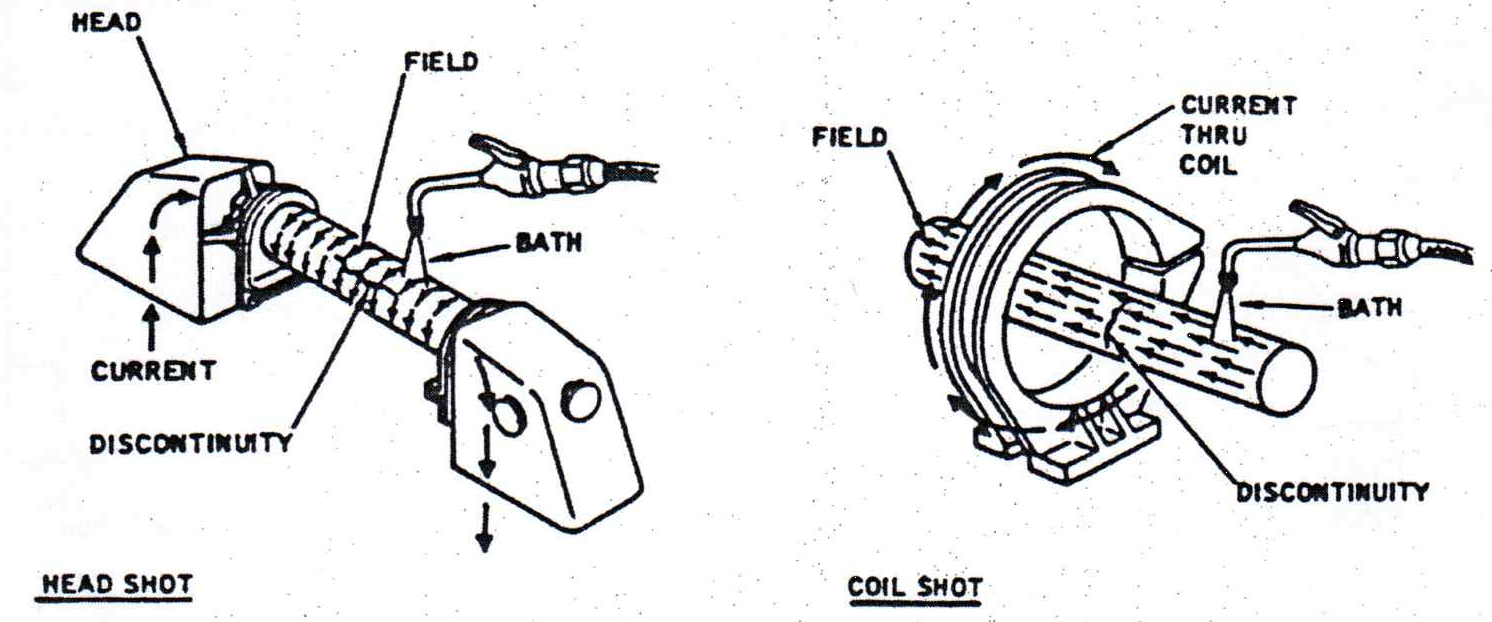

To obtain circular magnetization, the specimen is clamped between the head and tail stocks. For longitudinal magnetization the coil is moved so that the area to be tested is encircled by the coil. A typical wet horizontal unit usually accommodates both AC sand HWDC magnetization.

The wet continuous-field method has three basic steps:

- Flow bath through nozzle and over entire surface of part.

- Stop bath flow.

- Apply current at the instant bath flow is stopped.

Dry continuous-field method

With this method the powder is usually applied from a shaker, bulb, or Blower and follows these steps:

- Apply magnetizing current.

- Blow powder particles over magnetized area.

- Blow excess powder off part.

- Shut off magnetizing current.

The powder should float to the magnetized area so the particles will be attracted to any flux leakage. The dry powder method is typically used with both mobile and portable equipment which will be discussed on the following pages.

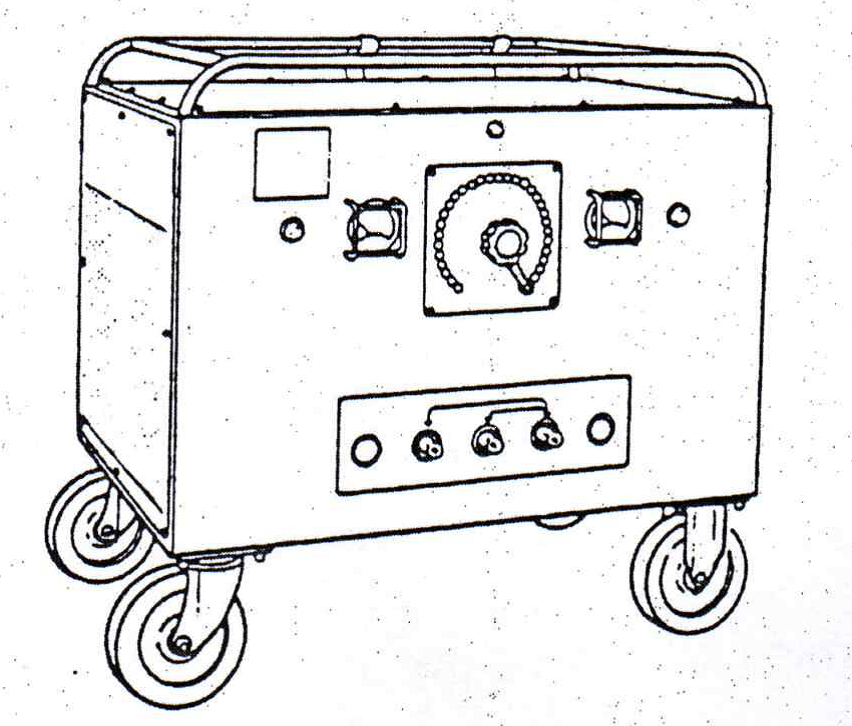

MOBILE EQUIPMENT

In many cases it is necessary to bring the equipment to the specimen. Typical mobile equipment such as the one above usually operates on 220/440 volts AC and will produce about 4000 amperes.

Mobile equipment will usually produce Both AC and HWDC magnetizing current. The cables used on the unit above vary from 15 feet to 100 feet. Shorter cables will permit the maximum current output.

Prods and cables are usually used with the mobile equipment. It often takes two technicians to manipulate the prods and apply the magnetic powder. However, longitudinal magnetization can be produced by wrapping the cable into a coil.

It is also possible to use a central conductor clamped between the cables to produce circular magnetization. Typical mobile equipment uses the dry powder method but can be used with aerosol cans or external tanks.

PORTABLE EQUIPMENT

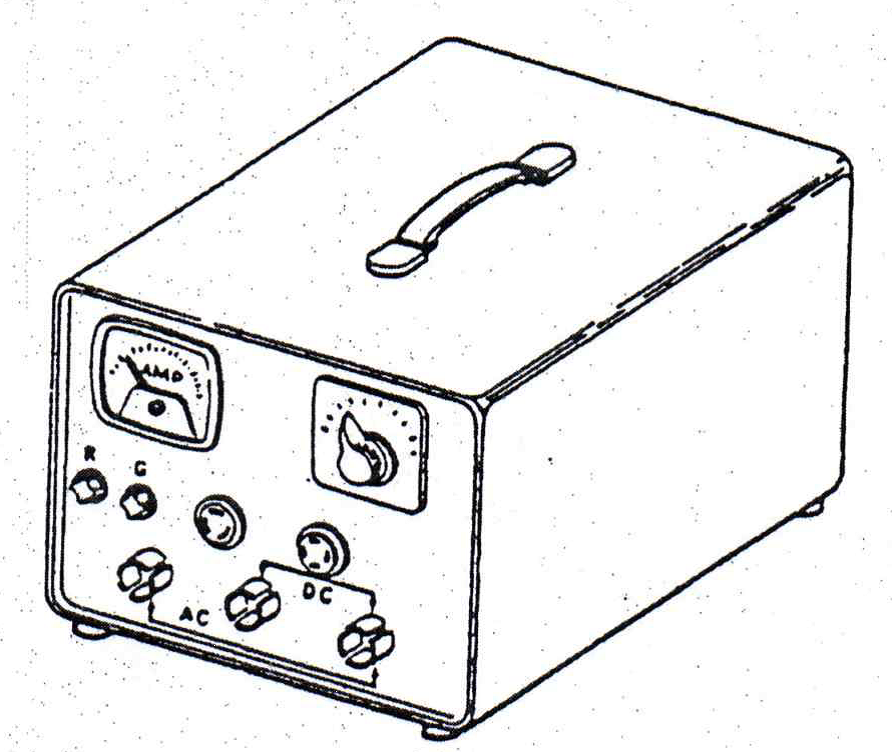

Portable equipment is lighter and less expensive than the other types of magnetic particle testing equipment.

Typical portable equipment as shown above operates on 110/200 volts AC with an output of between 500 and 1200 Amperes. These units usually have a choice of either AC or HWDC.

As with mobile equipment, the cables can be used for prods, wrapping into a coil, or connecting to a central conductor. Portable equipment also uses the dry powder method for most applications.

DEMAGNETIZING EQUIPMENT

The most common type of demagnetizing equipment consists of an open coil through which AC is flowing. A typical unit is shown below and includes a track will carry the part through the coil. As the part is carried away from the coil the magnetic field is reduced. The continuously alternating current in the coil completes the demagnetization.

LIMITATIONS OF MAGNETIC PARTICLE TESTING

- Nonmagnetic materials cannot be tested

- Magnetic particle testing will not detect discontinuities that are deeper than approximately ¼ inch below the surface.

However, the penetration depends on the permeability of the material, type discontinuity, and amount and type of current used.

SAFETY PRECAUTIONS

- Electrical arcing is hazard- It is usually caused by poor contact or by using excessive current. It can also be caused by allowing the prods to slip which may result in arcing or damaging the surface of the part. The arcing causes sparks which may result in a fire.

- The dust from the magnetic particle is nontoxic, but excessive amount should not be inhaled. Use a dust respirator.

- Smoking or open flame should not be permitted near the wet bath process.

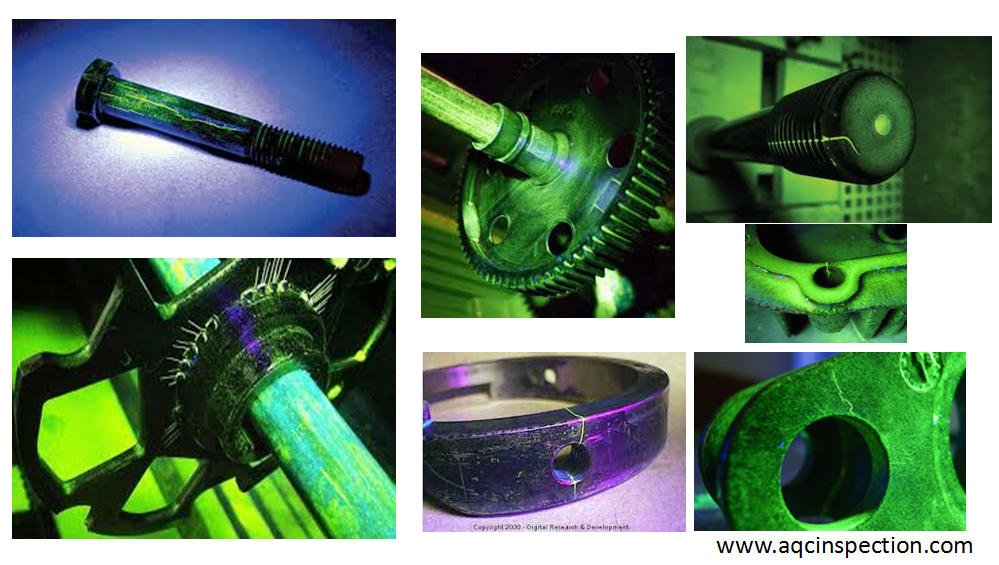

- The black light which is used with fluorescent particles will not damage the skin or eyes if the filters are used on the light. It is possible to experience a clouding of vision if the black light is directed into the eyes. This happens because the fluid in the eyes will momentarily fluoresce.

- Burns can be caused due to the resistance heating in the part or in the prods. Caution should be used in handling the parts or touching the prods immediately after the magnetic particle test.

The Procedure for Magnetic Particle Testing shall be prepared based on the requirement of inspection , let us know for guidance of Magnetic Particle Inspection

For best Non destructive Testing Inspection services and other Material testing services in Coimbatore and NDT certification , QC training contact us at https://aqcinspection.com/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com