Positive Material Identification (PMI)

A rapid, non-destructive method, positive material identification is performed on a wide range of components and assets, and provides a semi-quantitative chemical analysis. It is used for both material verification and identification. We provide best Mechanical Testing Services.

The method is utilised for quality control and safety compliance, and is an integral part of both production and asset integrity management across many industries including oil and gas, power, chemical, pharmaceutical, nuclear, aerospace and fabrication.

Positive material identification can prevent potential product failure in manufacturing. At oil and gas, power generation and pharmaceutical plants, pre-service and in-service inspection of critical components and welds with PMI can prevent breakdown and its costly consequences.

Positive material identification (PMI) Can:

- Ensure products/components have been manufactured using the correct alloy

- Find potentially mixed-up alloys

- Identify if the wrong material has been used

- Ensure material conforms to the correct standard and specification (both customer and industry)

- Ensure welded components have used the correct filler material

Positive material identification is performed using either of the two techniques below:

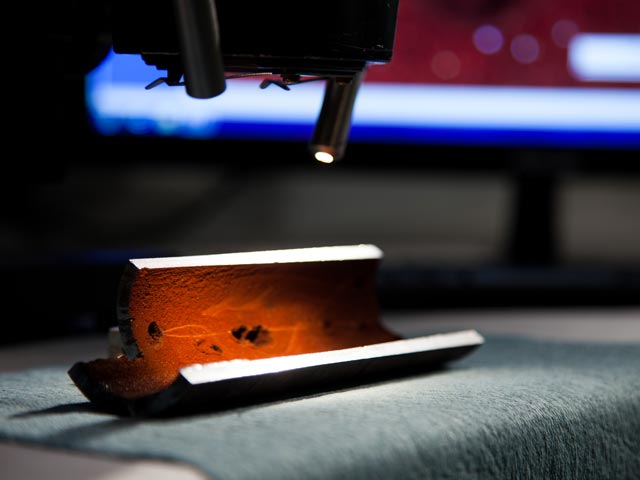

- X-ray Fluorescence (XRF) analyser: This is the most common method and the portability of the hand-held equipment allows AQC to perform PMI on-site at our customers’ premises. The device scans the metal material and identifies its key elements. However, it cannot detect carbon and some lighter elements and is not suitable for identification of pure carbon steel materials.

- Optical Emission Spectroscopy (OES): This method can detect almost all types of elements including carbon and lighter elements and carbon steel. Although not as portable as XRF analysers, the equipment can be transported to sites and used at high elevations with proper lifting arrangements.

Chemical Analysis – Spectrometer

Expert chemical testing and analysis services including composition analysis, trace contamination detection, metals testing, identification of unknowns and regulatory testing

Chemical testing and analysis is vital for regulatory compliance and to understand the quality and composition of chemical substances and materials that are used in products, industrial processes and manufacturing. Specialist industry knowledge, and expertise in applying the most relevant methodology are the keys to successful chemical testing. Advanced analytical instrumentation or a combination of techniques is necessary to solve problems or determine composition.

We provide advanced research and testing expertise, and operate under ISO 17025, Good Laboratory Practice (GLP), Good Manufacturing Practice (cGMP) and other recognized industry standards. We perform testing protocols according to standard methodologies (ISO, EN, BS, ASTM, DIN, etc.) and are experts in developing tailored analytical methods and performing method validation for specific testing applications.

Compression Testing

A compression test determines the behavior of materials under a crushing load. The specimen is compressed and deformation at various loads is recorded. Compressive stress and strain are calculated. The resulting stress-strain diagram provides information on elastic limit, proportional limit, yield point, yield strength and compressive strength.

Compression Testing:

- Compression of Composites ASTM D3410, ISO 14126

- Combined Loading Compression (CLC) of Composites ASTM D6641

- Compression of Plastics ASTM D695, ISO 604

- Compression of Unidirectional Composites using Sandwich Beam ASTM D5467

- Compression Set of Elastomers ASTM D395, ISO 815

- Hydraulic Composites Compression Fixture (HCCF)

- Compression of Matrix Laminates ASTM D6742

- Open Hole Compression ASTM D6484

- Compressive Strength of Damaged Plates (CAI) ASTM D7137

- Compression of Sandwich Core Materials ASTM C365

- Compression of Rigid Cellular Plastics ASTM D1621, ISO 844

Tensile Testing (along with hot tensile & elongation)

State-of-the-art tensile properties data generation for reinforced composites materials including tensile strength, tensile modulus and Poisson's ratio using align-pro, strain gages or extensometers performed at ambient, high or low temperatures with or without moisture conditioning.

ASTM D3039 tensile testing is used to measure the force required to break a polymer composite specimen and the extent to which the specimen stretches or elongates to that breaking point. Tensile tests produce a stress-strain diagram, which is used to determine tensile modulus. The data is often used to specify a material, to design parts to withstand application force and as a quality control check of materials. Since the physical properties of many materials can vary depending on ambient temperature, it is sometimes appropriate to test materials at temperatures that simulate the intended end use environment.

Bend Test

Universal Testing Machine with capacity up to 100kN is used to do tensile, compression & bend tests on materials, welded plates and pipes, the machine is equipped with a furnace for elevated temperature tests and extensometer to record the change in gauge lengths.

Micro Analysis

Micro examination is done under Microscopic to assess the grain structure of materials, also identifies any inclusions.

Macro Analysis

Macro-etch examination is done on weld fusion areas to check complete fusion and inclusions.

Impact Testing

Impact Testing machine is used to find the toughness of material and weld specimens, facilities are available to carry out low-temperature Impact Tests

Hardness Tests

Brinells Vickers or Rockwell hardness values can be found on materials, also portable hardness machines are available to check hardness values on-sight

Failure Analysis

AQC's failure analysis and investigation services identify the root causes of failures to improve future performance and solve problems.

Failure analysis and investigation can determine the root cause of failure should your product, component or asset fail or not perform as expected. The findings provide you with the insight to solve the problem, take remedial action and prevent recurrence.

At AQC, our scientists, technicians, engineers and inspectors are highly experienced and are experts in fields such as automotive technology, mechanical and electrical engineering, material science (metallurgy and polymers), chemicals, non destructive testing and industrial forensics.

Our services range from conducting analyses on failed engineering components and resolving failure issues for medical devices to investigating the causes of boiler tube failure in power plants, explosions and water losses.

We discover why materials and polymers fail and troubleshoot contamination issues. Our failure investigation services can be used to help improve product quality for consumer and retail goods if a product fails or does not perform as expected.

Paint Adhesion Tests

Holiday Tests