Welding Procedure Specification (WPS) is an industrial format procedure which consists of instructions how a particular welding should be made. It consists of all essential variables based on which only the company shall perform a welding. If any parameter goes above or below the mentioned essential variable parameter then the WPS is not valid and a new WPS shall be done for the requirement.

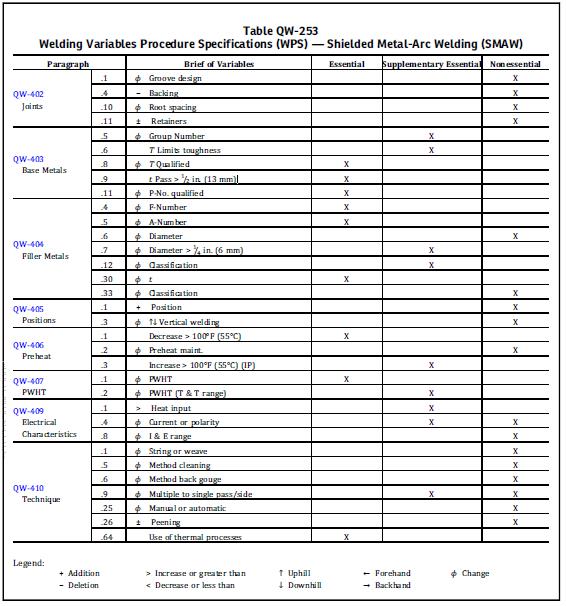

Example1: WPS essential Variable as ASME section IX-2019 is given in the below table:

Similar Essential Variables and range of qualification is given in the referencing Codes and Standards,

Few of the International Standards for WPS are given below:

- ISO 15614 – International Standard for WPS

- ASME Section IX – Boiler & Pressure Vessel Code

- AWS D1.1 – Structural Steel Welding Standard

- AWS D1.3- Sheet metal Welding (less than 5mm thick)

- AWS D1.6 –Structural Stainless Steel welding

- BS EN 15614 – British Standard (same as ISO 15614)

- AS/NZS 2980 – Australian Structural welding standard,

- CSA W47.1 and W59 – Canadian Welding Standards for Welder Qualification

For Preparation of WPS, the qualification range should be concluded referring the project drawings and existing production drawings. Depending on the wideness of the qualification the number of WPS required and test weld to be made will vary.

A preliminary WPS should be made which specifies the base metal, suitable filler metal, basic current requirements, backing gas requirement, heat treatment selection if required and dimensions of test coupon.

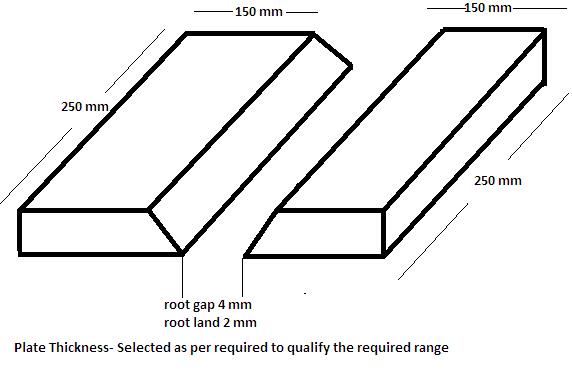

Example of test coupon dimension for a full penetration weld joint is given below:

A Test weld is made on the test coupon in the company facilities by the company welder (mostly best of the company welders). The test is made and paramaters such as Welding electrode dia, gas composition, flow rate, weld length, current (I), Voltage (V), Wire feed rate (m/s), Welding Travel Speed (m/s), Heat Input (kj/mm), cleaning methods, backing metal, welding technique, etc are noted as per actual.

All the welding parameters are controlled in a range such that the heat produced and cooling does not affect the quality of metal to perform the designed purpose. The work is done by a welding engineer or an experienced inspector.

Contact us for guidance by expertise for the specific task https://aqcinspection.com/

The welded test coupon is visually inspected for defects. If they are free of defects then it is recorded and the coupon is marked or stenciled with a test coupon number, name of welder, governing standard, grade of metal, WPS number if any and date of welding.

Volumetric NDE such as Radiography or UT is done and also Surface NDT such as PT or MPI is made as per the requirement in the referencing code.

Mechanical tests such as Tensile Test, Bend Test, Hardness, Impact Test, Micro Analysis, Macro Etch Analysis, etc are done on the welded test coupon. The Test to be done and number of specimens per test is mentioned in the referencing code.

What is a PQR ?

All the Welding data’s actually recorded during the test weld along is fed in the written Procedure Qualification Record (PQR)

The report number and results of the Non Destructive Tests made and Mechanical Tests made are also mentioned in the PQR.

After preparation of a PQR the Code is referred and Rages for each variable is found out, the ranges are mentioned in the Welding Procedure Specification.

Therefore WPS consists of all essential variables along with some non-essential and supplementary variables if needed with range of qualification.

For Example: welding a 10mm plate as per ASME section IX qualifies = 1.5mm to 20mm during production

Many manufacturers need independent approval for their welding procedures – either for compliance with international standards and codes or to comply with project requirements. Our welding specialists understand the codes or standards that are applicable to verify welding procedures and, as part of the third party witnessing process, we can:

- Create a Welder Procedure Specification (WPS) – a ‘technique’ card that documents how to produce a weld.

- Carry out non-destructive testing and destructive testing on the weld test piece produced under the WPS in our laboratories.

- Verify the weld test piece meets the applicable codes or standards

- Issue a Welder Procedure Qualification Record (WPQR) for the weld procedure, which qualifies the WPS

For NDT services and wps/wpqr/wqr services visit our https://aqcinspection.com/non-destructive-testing/

We also do complete analysis of metal properties by chemical analysis, Tensile Testing, Impact Testing, Hardness testing, Micro & Macro analysis etc. To know more about our testing facility visit https://aqcinspection.com/mechanical-testing-services/

Visit our blogspot website for more blog pages on http://advancedqualitycentre.blogspot.com