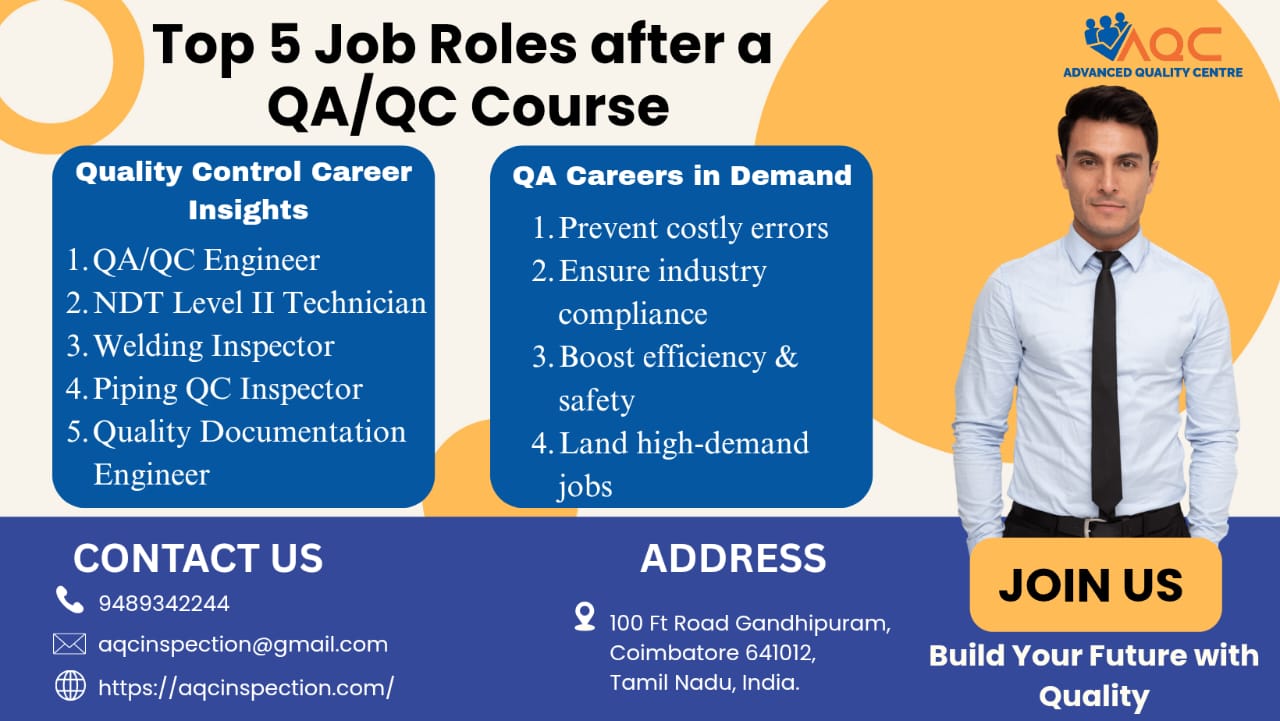

With the competition of today’s industrial community, QA and QC have become very important in every sector. We never even think of QA/QC in industries like Manufacturing, Oil and Gas, Construction/Automobiles/aerospace & Pharmaceuticals, we expect them to be top notch. We do these things to comply with regulations and so our products/services meet client standards. QA/QC check lessens flaws, decreases risks, improves safety, as manages and monitors systems at routine interval. Our QA/QC course helps with this.

Importance of QA/QC courseTraining

-

Prevents costly errors from defects

A simple manufacturing error, or a construction defect, can result in recalls of products, unsafe conditions for users, and litigation exposure. The QA/QC personnel are the ones who identify and remove defects in products before they arrive at customers.

-

Ensures Compliance with Industry Standards

Firms are required to comply with ISO, ASME, API, AWS, and other standards to operate officially as well as retain their accreditations. Without sound QA/QC in place, businesses run the risk of not passing an audit or receiving penalties for contracts.

-

Improves Efficiency & Reduces Waste

Companies can minimize material scrap, rework, and production delays through the application of systematic quality checks. That translates into more productivity and cheaper costs.

-

Improves Customer Satisfaction and Brand Perception

Good products create customer trust and repeat sales. Low quality makes a company’s reputation take a hit, and it may lose clients.

-

Opens High-Demand Career Opportunities

As quality becomes an ever more important focus for industries, demand is high for experienced QA/QC personnel. Companies are willing to pay top dollar for inspectors and engineers who have been certified, testing experts reported.

1. QA/QC Engineer

What Does a QA/QC Engineer Do?

A QA/QC Engineer is responsible for ensuring the quality of a product or process. Their main duty is to guarantee our products meet all international quality standards such as ISO 9001, ASME, and API with systematic inspections & testing procedures.

Key Skills Required:

✔ Familiarity with ISO 9001, ASME, ASTM, and API standards

✔ Read and interpret engineering drawings, plans, and specifications

✔ Knowledge of quality control tools (SPC, FMEA, Root Cause Analysis)

✔ Good analytical and problem-solving skills

How You’ll Be Prepared with Our QA/QC Course:

- Quality management systems (QMS)

Inspection methodologies (visual, dimensional testing of materials).

- Documentation and reporting

- Real industry projects, Hands-on training

-

NDT Level II Technician

What Is Non-Destructive Testing (NDT)?

Non-Destructive Testing (NDT) encompasses a wide range of testing methods that evaluate the properties and integrity of a material or component without causing any damage. Common NDT methods include:

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Magnetic Particle Testing (MT)

- Liquid Penetrant Testing (PT)

- Eddy Current Testing (ET)

- Visual Testing (VT)

Key Skills Required:

✔ NDT Level 2 qualification certificate (ASNT/PCN/ISO 9712)

✔ Knowledge of welding, casting, and forging imperfections

✔ Skilled at judging the results of tests accurately

✔ Proficiency in NDT safety precautions

How Our QAQC Course Prepares You:

- Practical NDT course (UT, RT, MT, PT, and VT)

- ASNT NDT Level II certification guidance

- Industry-relevant case studies

- Placement support for top companies

-

Welding Inspector

What Does a Welding Inspector Do?

For anyone dealing with structures or materials, a welding inspector is essential in ensuring safety and checking for imperfections in the metal being produced to meet all AWS (American Welding Society), ASME (American Society of Mechanical Engineers), & API (American Petroleum Institute) code/standard requirements. They scrutinize the weld joints, base metals, and filler materials for evidence of good fusion and lack of defects such as cracks or porosity.

Key Skills Required:

✔ CSWIP or AWS-CWI Certification

✔ Knowledge of welding symbols & qualification procedures (WPS/PQR)

✔ Experience of VT and weld examination techniques

✔ Knowledge of metallurgy and defects in welding

What You’ll Learn from Our QA/QC Course:

- Methods of welding inspection (VT, MPI, DPT)

- CSWIP/AWS-CWI exam preparation

- Mock inspections and fieldwork

- Assistance in job placement as a welding inspector

-

Piping QC Inspector

What Does a Piping QC Inspector Do?

Piping QC Inspector is an essential position to ensure the pipes used in various industries like oil & gas, chemical, or power plants retain their material integrity. They ensure that B31.3, API 570, and other industry codes are followed by performing thorough examinations of materials, welds, and installations. With various methods such as visual inspections, dimension checks, and non-destructive testing (NDT), they detect defects while controlling alignment or pressure resistance.

Key Skills Required:

✔ Knowledge of ASME B31.3, B31.4, and API 570

✔ Welding, Hydrotesting & Alignment Checks Experience

✔ Ability to read P&ID and isometric drawings

✔ Knowledge of material verification (PMI testing)

How You Are Prepared by Our QA/QC Course:

- Piping codes and standards

- Checking methods (visual, dimensional NDT)

- Hydro test and pressure testing methods

- Job-ready certification programs

-

Quality Documentation Engineer

What Does a Quality Documentation Engineer Do?

A quality document engineer is responsible for organizing and keeping all quality documents, such as inspection reports, MTCs, and compliance certificates. They also maintain accurate records of welding logs and NDT reports, as well as calibration, to satisfy ISO, ASME & client requirements. They smooth internal and third-party audits by controlling electronic and physical quality records.

Key Skills Required:

✔ MS Office & QA software (SAP QM, QMS tools) literacy

✔ Knowledge of what is required in ISO documentation

✔ Attention to detail to ensure records are precise

✔ Knowledge of regulatory conformance (i.e., OSHA, FDA, etc.)

How You Are Prepared by Our QA/QC Course:

- Quality documentation best practices

- Electronic QMS tools training

- Audit prep and compliance reporting

- Documentation of career guidance

FOR MORE INFORMATION AND TRAINING

CALL NOW @ 8668082413 @ 9600640894