How to get Welder Certificate ?

I will guide you here for attaining yourself or your employer an welder qualification certificate. Welding is an operator skill based process which should be controlled by a proper welding procedure (WPS), The welding process involves liquefying the base metal by heating and the allowing it to cool to join one together, the heating can be done by various method such as electric arc, gas flame torch, friction stir, electric resistance or any other means.

- Arc welding– done by creating and electric Arc, their sub categories are as below:

Shielded Metal Arc Welding (SMAW/ MMAW) Manual Metal Arc Welding

Metal Inert Gas Welding (MIG) / Metal Active Gas (MAG)/Gas Metal Arc Welding (GMAW )

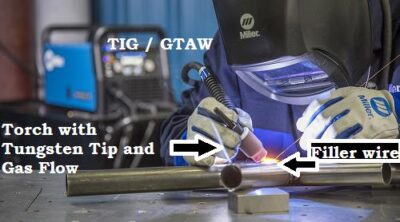

Tungsten Inert Gas Welding (TIG / GTAW)

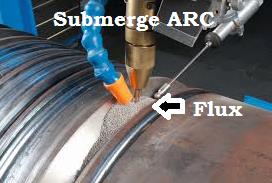

Submerged Arc Welding (SAW)

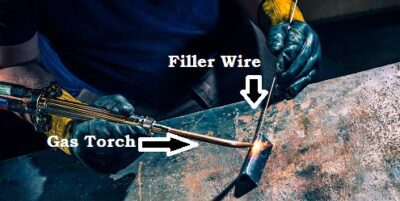

- Gas welding – done by flame created from burning gases and heating the metals, example: Oxy fuel welding

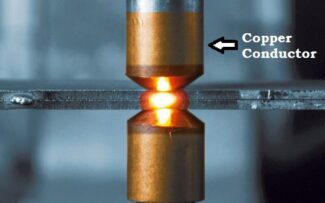

- Electric Resistance – done by passing current through the material itself and applying pressure on the ‘to be joined areas’

-

Friction Stir – done by heat due to friction caused by rubbing the metals to be joined

And lot more………………

What is difference between a welder & welding operator ?

The person who performs the operation is called a welder or welding operator

Person Performing Manual welding and Semi Automated Welding are called Welder

Person Performing Automated Welding is called Welding Operator

The Person performing the weld should carry a welder qualification certificate , as per many of the industrial standard & project standard, So company’s having their welders qualified for their welding process are more likely to get more orders.

A proper welder certificate impresses your client, continue reading to know what are the requirements to qualify a welder

To qualify a welder there should be a written Welding Procedure Specification- WPS.

What is WPS / PQR ?

WPS – Welding Procedure Specification is the company document that shows the client what welding process the company is qualified to do and what is the range of material grade and thickness range the company is capable to do, and also it instructs the welder the parameters to be set during welding of a particular grade and thickness using a specific welding process.

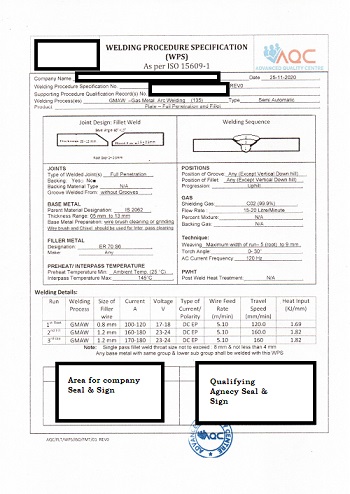

Find below the example of Welding Procedure Specification:

Industrial Standards of International bodies has procedures to qualify a welder , few of international bodies are given below

- International Standards Organization (ISO),

- American Society of Mechanical Engineers (ASME),

- American Welding Society (AWS),

- British Standards of European Nation ( BS EN),

- Standards of Australia and New Zealand (AS/NZS),

- Canadian Standards Association ( CSA ) and lot more.

The Reference Standard for Welder Qualification are given below :

Welder Qualification Standards:

- ASME Section IX – welder qualification for Boilers, Pressure Vessels and Pipelines

- AWS D1.1 – For Structural Steel Welding

- AWS D1.3- For Sheet metal Welding (up to 5mm thickness )

- AWS D1.6 – For Stainless Steel Structures welding

- ISO 9606 – International Standard for Welder Qualification

- BS EN 287 – British Standard for Welder Qualification (replaced by ISO 9606-1 in 2015)

- AS/NZS 2980 – Australian Structural welding standard,

- CSA W47.1 and W59 – Canadian Welding Standards for Welder Qualification

How to Qualify Welders?

Generally welders are qualified at the company’s facility;

Test samples either Plates or Pipes is given to the welder, the thickness of plate and Pipe, and diameter of pipe is selected as prescribed in the WPS & reference standard, the fitup is made in the position the welder is to be qualified, The root gap and bevel preparation are as given in te WPS.

The Welding Positions for welder Qualifications are as below:

for Butt weld plates and structures: 1G-Flat, 2G-Horizontal, 3G- Vetical (Uphill / Downhill), 4 G- Overhead

for Fillet Weld Plates and structures: 1F-Flat, 2F- Horizontal, 3F- Vertical (Uphill / Downhill), 4F – Overhead

for Pipe : 1G- Horizontal Pipe rotated, 2G – Vetical, 3G- Horizontal Pipe Fixed, 6G – 45° inclined , 6G-R – 45° inclined with retainer plate.

The welder is made to weld the fit up test sample, the welding should be made following the parameters in WPS.

The welded test plate or pipe should be visually tested along with a surface defect detection NDT method.

Other additional tests such as Radiography Testing, Bend Tests, Macro Analysis, Fillet break test, etc, which is specified in the reference standard should be carried out on the welded test coupon.

If all the tests passes the welder shall be qualified, and a welder qualification certificate shall be produced with all the essential variables mentioned in it.

Contact us to help you making a perfect Welding Procedure Specification and Welder Certification at very low charges, the certificates will be attested by a competent welding inspector qualified by The Welding Institute TWI, UK.

For welding procedure specification (WPS) and welder certification visit https://aqcinspection.com/non-destructive-testing/

For more details and updates on welder Qualification and Welding procedure specification Visit our blog on https://advancedqualitycentre.blogspot.com/