Non-Destructive testing (NDT) plays a vital role in ensuring the safety, reliability and efficiency of any industrial structures and equipment. Some of the Industries such as manufacturing, oil and gas, aerospace, power generation, and railways mostly rely on NDT to detect flaws without causing damage to any of the tested components. Proper training and certification in NDT Level 2 is essential which truly ensures accuracy, compliance and career growth in this field.

Non-Destructive Testing:

NDT consists of set of inspection techniques which is used to evaluate materials, components and systems without causing any damage. Training and certification in NDT become crucial while performing this powerful technique. Their effectiveness depends on the skill and knowledge of the technician performing them. Some of the common NDT methods include:

- Ultrasonic Testing – Internal flaws are detected using high frequency sound waves.

- Radiographic Testing – Inspect internal structures which employs X- rays and gamma rays.

- Magnetic Particle Testing – Ferromagnetic waves detect the surface and near surface defects.

- Liquid Penetrant Testing – Uses colored or fluorescent dye which reveals surface-breaking flaws.

- Eddy Current Testing – Cracks and Corrosion in the Conductive materials are found using electromagnetic induction.

- Visual Testing – Cameras and Drones are often aided to inspect.

Why Training and certification in NDT matters ?

-

Ensure Accuracy and Reliability

NDT inspection must be precise as minor can lead to catastrophic failure. Cracks, Corrosion or Voids leading to equipment failure.Safety hazards and Costly shutdowns are some critical defects missed by some poorly trained technicians. Certified professionals with ASNT NDT Level 2 are trained to

- Operate Testing Equipment.

- Interpret Accurate results.

- Ensure Standardised procedure.

This Professionals inspects in the high stakes industries like nuclear power, aviation, and oil refining and ensures the reliability and helps in reducing risks.

-

Meet Compliance with Industry standards

Many of the industries operated under strict regulations set by the organisation like:

- ASNT – American society for Non-Destructive testing.

- ISO 9712 – International NDT Certification Standard.

- SNT-TC-1A – Recommended practise for NDT personnel.

-

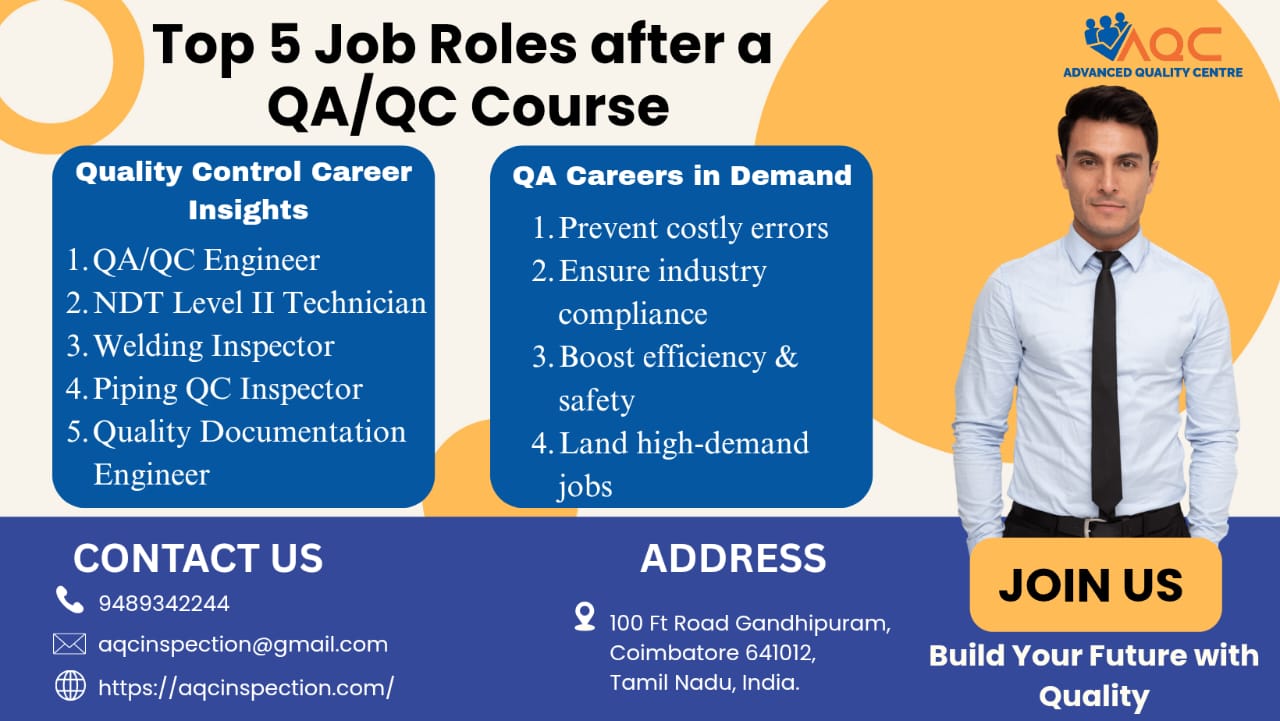

Increase Career Opportunities

NDT is one the global demand skill driven profession, certification especially in ASNT NDT Level 2 is opens a way for higher paying roles in the industries like Aerospace, Oil and Gas, Power Generation, Automotive and Railways. These level 2 certified professionals can

- Supervise level 1 personnel

- Conduct inspection on their own

- Interpret and report

-

Improves safety and prevents failure

NDT is often used to safeguard the component before it is approved for use. A small undetected flaw in an aircraft wing, a pressure vessel, or a bridge weld can lead to biggest disasters.

- Identify defects at the earliest

- Prevent corrective actions

- Prevents accidents and corrective actions

Understanding NDT Certification levels:

There are three different certification levels such as level 1, level 2, and level 3 in Non-destructive testing (NDT) which reflects increasing expertise and responsibilities. It ensures that the technicians are qualified to perform inspections accurately and safely.

Level 1 – Entry level technicians

Entry level technicians perform basic test under supervision and ideal for beginners to gain hands on experience. This level follows written instructions but do not interpret the results. In level 1 the technicians were not analysing the results. However, their primary emphasis is on executing the procedures as instructed and mastering the fundamentals of the role that they performed. This position is perfect for the entry level personnel who needs to acquire practical skills.

Level 2 – Intermediate Technicians or NDT Engineers

Intermediate-level technicians take on more serious tasks, such as preparing and calibrating equipment to ensure accurate testing. Well, they can even handle their own inspections, tapping into their knowledge to identify issues and to ensure everything runs smoothly. Unlike low level employees, they scrutinize and evaluate results, making intelligent conclusions on what they find. They could supervise the Level 1 technician, telling them what to do or helping them improve their skill-set. This role requires an understanding of concepts and the ability to work independently.

Level 3 – Senior NDT Staff: The Wizards Behind the Curtain

Level 3 NDT technicians are the highest-level pros in Non-Destructive Testing—they write the rules, train the teams, and are the ones who have to make the big decisions. While Level 1 and Level 2 technicians simply follow procedures, these specialists create and sanction their own testing protocols. These protocols make certain inspections are performed to the highest industry and safety standards. They’re also in charge of training and certifying advanced junior technicians. Also passing down their knowledge as a way to maintain a skilled workforce.

Why Continuing Education Is Key to the Future of NDT

The NDT is progressing; the new technologies are being used and it’s necessary to continuous learning. Some emerging trends include:

Digital Radiography (DR)

Digital Radiography (DR) is transforming the way of traditional inspection by substituting the require for film to be used with a digital image receivable from an image detector. It is an effective way to get high-quality images as it does not need to be chemically processed. This means an available image is made and visible within seconds. Additionally, the technology improves image analysis with options such as zoom, contrast adjustment and defect quantification. Thus we can ensure reliable fault detection. But DR is something that has to be learned through special training in exposure skills, calibration procedures and digital image interpretation.

Phased Array Ultrasonic Testing (PAUT)

PAUT employs multiple electronically controlled ultrasonic elements that allows steering and focusing of beams for very detailed inspections. This powerful technique is especially well-suited to interrogate complex geometries, such as welds, pipelines or curved components, when conventional UT may prove inadequate. Nevertheless, the operator of PAUT systems has to be very well trained with respect to beam steering, calibration and scanning plan to achieve accurate detection of defects. The technician also needs to possess high quality of data interpretation skill, as the PAUT examination provides the good cross-sectional image and these images require expert analysis. It has made the PAUT certified professional more in demand for specialized skills.

Time of Flight Diffraction (TOFD)

TOFD (time of flight diffraction) is a highly accurate ultrasonic inspection technique used to detect the exact location of internal flaws. It is frequently used with PAUT weld inspections for a complete view into potential faults. TOFD works on the principle that the sizes and location of the flaw can be accurately measured using the diffracted sound waves unlike traditional methods. This type of technology is critically beneficial in industries such as pipeline and pressure vessel inspection. Proficiency in TOFD depends on satisfactory theoretical knowledge and practical experience, and the production of reliable results, in difficult testing situations.

RVI- Remote Visual Inspection with Drones

RVI with Drones makes us to understand how we inspect hard-to-reach structures, such as wind turbine blades, tall pipelines and platform shafts. These specialised drones are loaded with high-resolution cameras, heat-mapping sensors. In some cases, ultrasonic equipment to capture detailed inspection data without putting workers at risk. Inspection personnel also require a data management know-how for processing, analysis and presentation of the acquired visual information. While this cost-saving potential is leading to greater industry utilization of this cutting-edge technology, certified RVI drone operators are in greater-appreciated demand for providing safer, quicker, cost-efficient inspections.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . orhttps://ndtcenter.blogspot.com

Subscribe our youtube channel to know more practical explanations https://aqcinspection.com/