LIQUID PENETRANT EXAMINATION (PT)

Pentrant Testing is surface defects detection method, the method can be used on any material ( i.e: Ferrous/ non-ferrous, conductive/ non conductive, metals/ non metals)

But PT is limited to materials having porous surface or very rough surface.

PT can be carried out on castings, raw material, machined faces and weld joints. It is more often used in Austenitic Stainless Steels, where MPI inspection is not practically possible.

Most standards insist that the penetrant materials used, should not contain contaminants that spoil the quality of weld and metals.( contaminants such as Sulphur, Chlorine & halogens )

Penetrant materials are mostly suitable for materials with surface temperature less than 52°C. Therefore the weld has to allowed to cool before carrying out PT test on it.

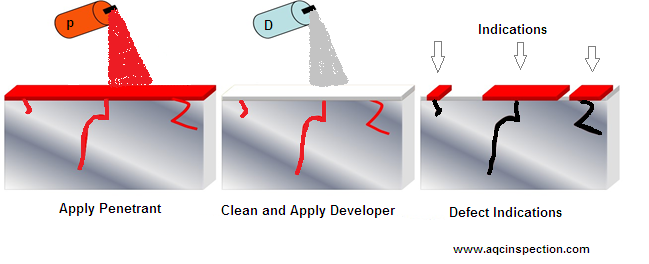

Liquid penetrant testing principle

Any PT inspection on elevated temperature (temperature other than 4°C to 52°C), should have special qualification on the Consumables. As described in the ASME BPVC section V- Article 6 – Mandatory Appendix 3.

Most essential part of the test is Pre-Cleaning. It is a critical step, because any left out dust, spatter, chips, burrs, oil, grease, rust, etc, shall mask the discontinuity and will not show –off during PT.

Penetrant testing procedure

The Steps of Penetrant Testing are as below

- Pre-cleaning of the Test Surfaces , using any suitable means

- Penetrant Application (by spraying, flowing, dipping, brushing or any suitable means)

- Dwell Time (wait for 5-10 minutes , or as told in the procedure you follow)

- Excess Penetrant Removal (after dwell period remove of the pentrant over the surface as per the suitable method for the penetrant – Solvent removable / Water Wash/ Emulsify and wash)

- Apply Developer ( Apply developer over the surface by spraying/flowing/dipping or any other means)

- Developing Time (wait for sufficient time for the developer to dry, normally 10 minutes for Solvent based developer) . Generally indications starts appear by blotting action of the developer

- Interpretaion Find out the bleed out indications and decide the acceptability of the indication. Interpretation should be completed between 10 to 60 minutes after development. Deeper the defect, wider the bleed out indication.

- Post Cleaning – clean the surface using cloth or any suitable means, to let the components for next process.

Dye penetrant inspection

The two types of inspections are 1) Visible Inspection and 2) Fluorescent Inspection

- Visible inspection uses color contrast die and inspection carried out under white light, visible Light should have a light intensity of 1000 Lux

- Fluorescent inspection uses Glowing fluorescent dies and done under Ultraviolet Lamps, UV Lamp should have light intensity of 1000 µW/cm² at the surface inspection.

- A dark room setup is required for Fluorescent inspection with a maximum white light intensity of 20 Lux

What are the requirements of Liquid Penetrant Testing?

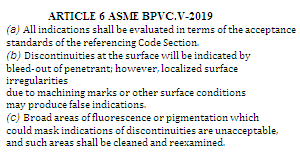

The ASME Section V, Article 6, describes the requirements of Liquid Penetrant Test (PT)

API 650, ASME B31.3 and ASME Section VIII, Division 1, all requires the PT inspection to be done as per ASME BPVC- Section V- Article 6.

For carrying out the inspection and signing off the reports the personal should be trained and qualified by ASNT norms SNT-TC-1A.

The person should have cleared eye tests – Near Vision test Jagger’s J1, Color blindness test – Ishihara test, and the employer should carry out the test on personals annually.

For more detail of dye Penetrant inspection in NDT and Liquid Penetrant testing services in Coimbatore feel free to contact us at https://aqcinspection.com/ and for other mechanical testing services

For training on non-destructive testing methods, QC courses and ndt courses contact https://aqcinspection.com/training/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs