blogs

blogs

blogs

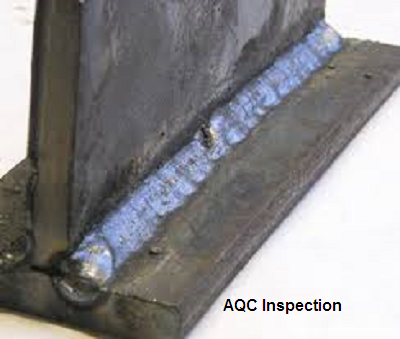

Duties of Welding Inspector

Visual Inspection Inspection Stages: Inspections should be performed at different stages of the welding process, including tacking, root pass, filler pass, and cap pass, with particular attention paid to the root and cap areas. Responsibilities of the Inspector: Observe, identify, and possibly measure…blogs

Laser Welding Process & Laser Welding Machine

What is Laser Welding? Laser welding process is a technique that utilizes a concentrated beam of light, or laser, to fuse materials together. The intense heat from the laser beam melts the base materials, which, upon cooling, create a strong and durable bond. This process…blogs

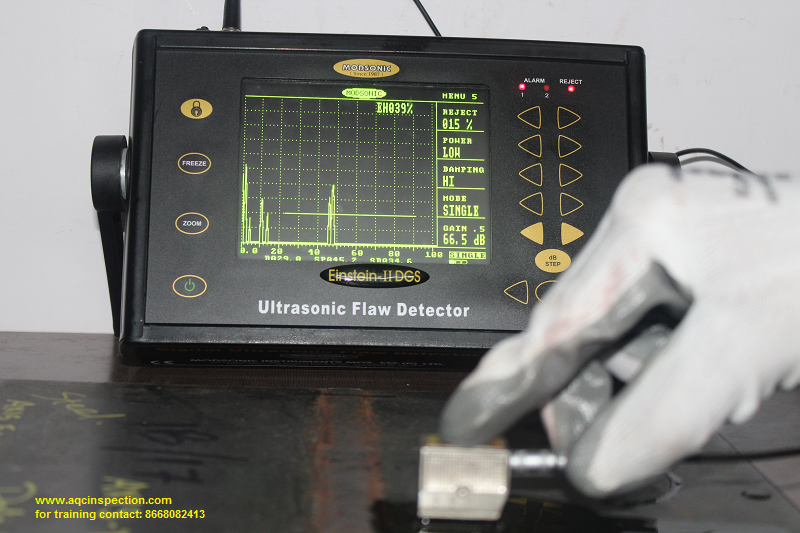

NDT Accessories

Non-Destructive Testing (NDT) accessories are essential components that support NDT techniques used to evaluate the integrity and properties of materials or structures without causing damage. NDT is widely used in industries like aerospace, construction, manufacturing, oil and gas, and more. The accessories used in…blogs

Welding repair – Fabrication defects and service failures

Introduction Welding repair of defects ranges from simple operations to improve the weld profile to more extensive procedures involving significant metal removal and subsequent rewelding to address extensive cracking. Repairing defects that occur during fabrication is generally easier than addressing service failures because the same…blogs

Welding Procedure and performance qualification

Welding Procedure and performance qualification – ASME Section IX Welding Procedure Specification (WPS) A Welding Procedure Specification (WPS) is a written document that provides detailed instructions to the welder for making production welds in accordance with code requirements. Every WPS must be qualified by the manufacturer….blogs

GTAW Welding on Stainless Steel

GTAW Welding on Stainless steel – SS Produces very strong/tough weld compared to other process Slow process Good appearance Mostly used for Root and hot pass & Low thickness material Low heat input…blogs

SMAW – Shielded Metal Arc Welding on SS Material

Arc welding on SS material : Electrode specification standard : AWS A 5.4 Gas – Not required Example of electrode spec: Austenitic SS : E209, E316, E308, E309, E316, E316L (L – Low Carbon), Martensitic : E410-16 Precipitation hardened : E7Cr-16 Enclosed herewith the Electrode selection chart for…blogs

Welding on Stainless Steel

Stainless Steel They are similar to steel (having Ferrous and carbon) , but chromium content is more than 10.5% thus making it more corrosion resistant What are the types of Stainless Steel ? (based on the grain structure): 1) Ferritic (ex: SS type 409, 430, 442…blogs