Stainless Steel

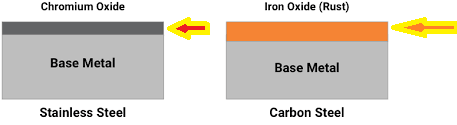

- They are similar to steel (having Ferrous and carbon) , but chromium content is more than 10.5% thus making it more corrosion resistant

What are the types of Stainless Steel ? (based on the grain structure):

1) Ferritic (ex: SS type 409, 430, 442 , 444, etc)

2) Martensitic (ex: SS type 410, 420, 440A )

3) Austenitic (ex: type 201, 303, 304316, 310, 321)

4) Duplex & Super Duplex – with both ferritic and austenitic property (ex: 2205, 2507, ASTM A789 UNS 32520 )

5) Precipitation hardened SS – with both martensitic and austenitic property, can be heat treated to have good strength (ex: 17-4 PH)

- SS is categorized as such based on the micro structure which in turn results in different ductility and strength

- Austenitic steel contains 16-26% chromium (Cr) and 8-22% nickel (Ni).

- Martensitic steel has a Chromium (Cr) 11-28%.

- Ferritic steel runs 12-18% Cr.

Is gas cutting possible on Austenitic Stainless Steel ?

Ans : No, Oxy Acetylene gas cutting is not possible on Stainless Steel , because of the Chromium oxide layer present on the surface , chromium oxide layer is naturally formed over the surface during making of the product due to presence of high chromium content , this oxide layer is use full for corrosion protection .

- The melting point of the oxide layer is much more than the base metal

- Melting point of SS is 1400 °C-1450°C (Aluminium : 660°C)

- But melting point of Chromium oxide layer is 2435°C (Aluminium : 2050°C)

Because of the difference in melting point the inner material is melted prior to the melting of the top chromium oxide layer. This results in poor finish in the cutting area .

How to cut stainless steel ?

- Band Saw Cutting

- Jig Saw Cutting

- Circular Saw Cutting

- Plasma Arc Cutting

- Lazer Cutting

- Water Jet Cutting

Preparation of SS Welding surface before welding :

- Use separate tools for SS & MS

- Do not bring in contact with the Steel items

- Use cutting wheel of SS Grade

- Use SS Wire brush only

- Do not use Iron hammers , instead use Nylon hammers

- Do not lift with Chain blocks ,lifting chains, Fork lift with steel fork,

- Make sure any liquid or chemical used on SS material has no chloride content in it

- Handle the material with Gloves only,

- Contact with any Steel will cause contamination and will cause rusting of SS material in the near future .

- Purging / Gas Backing

- Purpose to prevent oxidation in the root side of weld in butt welds

- Oxidation in root will result in undesirable weld profile, reduced corrosion resistance and

- Argon or Helium

- Gas flow rate: 5-7 LPM only required for the root weld

Welding on Stainless Steel SS material process:

- GMAW

- FCAW

- GTAW

- SMAW

- ERW

In next blog we shall learn about the suitable welding electrodes and parameters for different welding on stainless steel process & pickling/ passivization .

For more training or certifications for welding operator , please feel free to contact us through [email protected], [email protected], https://aqcinspection.com .

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

No Comments