blogs

blogs

blogs

NDT Methods Selection

NDT Method Selection: The NDT (nondestructive testing) methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT Eddy Current Testing – ET (not used in field inspection) Acoustic Emission Testing –…blogs

Non Destructive Testing- Course and NDT course Fee

Non Destructive Testing has plenty of scope for people interested in Mechanical Industry and also construction sector. This Quality Control Related subjects is thought in almost all major cities all over the world, and the NDT certificates offered by institutes are valuable across the globe. The…blogs

Weld defects

Failure investigation often uncovers facts that lead to changes in design, manufacturing, or operating practice, which will eliminate similar failures in the future. Failures of insignificant parts can also lead to advances in knowledge and should be done objectively, as with a large structure. The…blogs

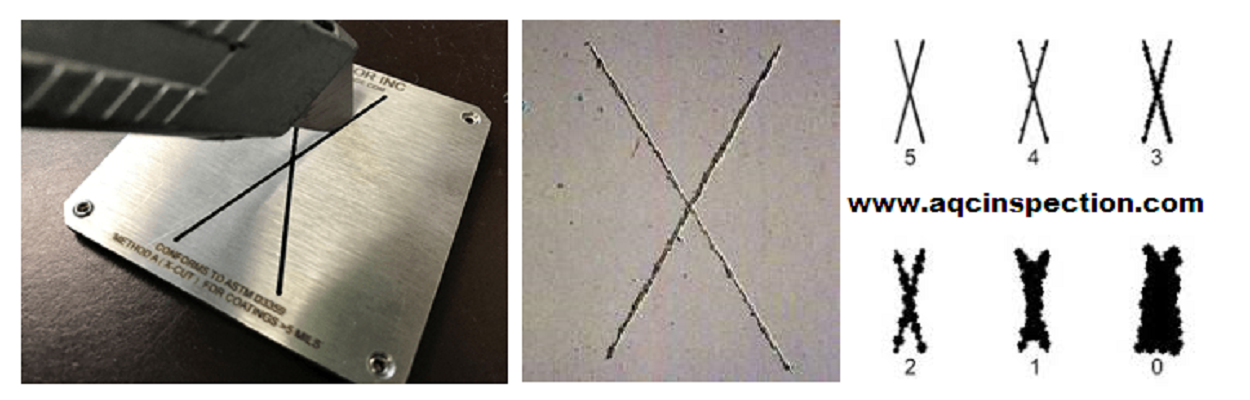

Adhesion Test on Paints by Tape Test

Painting Inspection, Adhesion Test, QC Training, QC Course X Cut Test (This Document) Cross Cut Tape Test Method A – X Cut Tape Test An X-Cut is made on the Dry Paint until the bare substrate , a…blogs

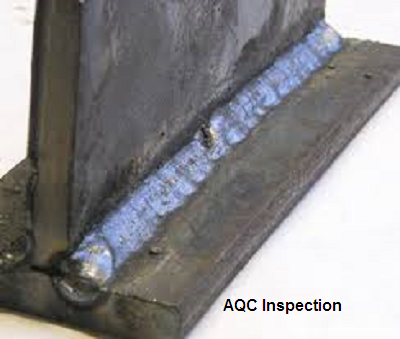

Concepts of Welding Defects and Discontinuities

Welding defects can be classified as structural discontinuities and consist of: porosity, slag inclusions, lack of fusion, cracks, etc. Porosity is gas pockets or voids in the weld metal which are free of any solid materials, such as It is formed as a result…blogs

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2 This blog here answers your questions about: What is the tolerance for Fillet weld sizes as per AWS D1.1 ? What is the weld size tolerance? What is the required fillet weld size for structures…blogs

NDT Course fees

NDT Course fees depends on the type of NDT Course Selected, such a number of methods and the International standard chosen for the certification The Average course fees for General NDT course will be Rs.17500, This course fees Rs.17500 is for ASNT Level II Certification course…blogs

Fillet Weld Types

Fillet Weld Types: The single-fillet-welded T-joints are indicated from both the arrow side and the other side. The symbol for a double fillet-welded T-joint is also Note that the assembly of two T-joints welded pieces involves four fillet welds represented by two double-fillet-weld symbols.blogs