blogs

blogs

blogs

Concepts of Welding Defects and Discontinuities

Welding defects can be classified as structural discontinuities and consist of: porosity, slag inclusions, lack of fusion, cracks, etc. Porosity is gas pockets or voids in the weld metal which are free of any solid materials, such as It is formed as a result…blogs

NDT Course fees

NDT Course fees depends on the type of NDT Course Selected, such a number of methods and the International standard chosen for the certification The Average course fees for General NDT course will be Rs.17500, This course fees Rs.17500 is for ASNT Level II Certification course…blogs

NDT – Few Other Methods

Here are some rarely used NDT – Few Other Methods 1. Eddy Current Testing – ET: Eddy-current inspection uses electromagnetic induction to detect flaws in conductive materials. A circular coil carrying current is placed in proximity to the test specimen (electrically conductive). The alternating current in…blogs

Non destructive Testing (NDT)- Common Methods

Non destructive Testing (NDT)- Common Methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT 1. Visual Inspection – VT: Visual inspection after welding is very useful in evaluating quality, even if…blogs

Discontinuities in Ultrasonic Testing in NDT

This blog will discuss types of discontinuities that can be evaluated with the ultrasonic testing in NDT method. Discontinuities can be divided into three general categories inherent, processing and service Inherent discontinuities are usually formed when the metal is molten. Inherent wrought discontinuities relate to the…blogs

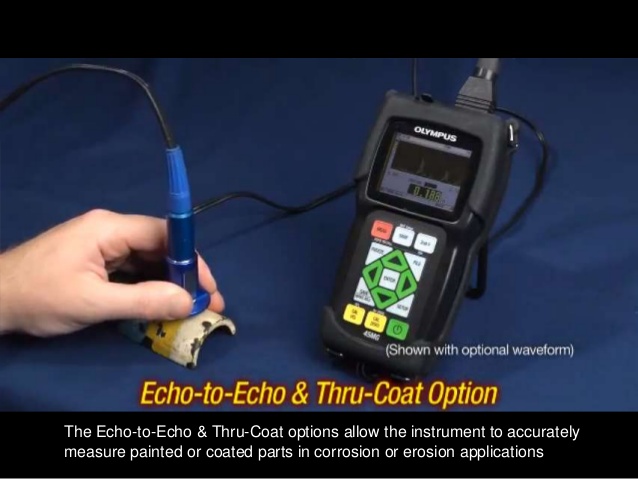

What is Ultrasonic Thickness Testing ?

Ultrasonic Testing Ultrasonic Testing utilizes high frequency sound waves which are not audible to human ears. The Ultrasonic sound waves are used for measurements of thickness of any material. General frequency used in ultrasonic thickness measurements probe is 5 Mega Hertz and above. The probe is placed over…blogs

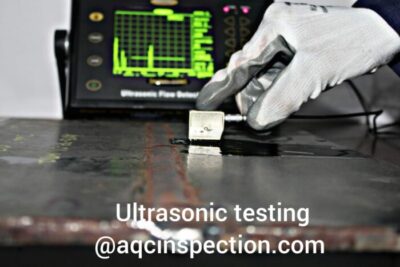

Principle of Ultrasonic Testing

This blog will let you know about the principle of Ultrasonic testing What is Ultrasonic Testing? Ultrasonic Testing Uses high frequency sound energy to conduct examinations & make measurements. It can be used for flaw detection, Dimensional measurements.blogs

Ultrasonic Testing for materials

What is Ultrasonic Testing? ULTRASONIC TESTING is a method for sending ultrasound into material and analyzing the returning sound waves for defect free components. It use scanning devices called probes. After application of Couplant over the material surface probe is place over the material. The sound travels…blogs