blogs

blogs

blogs

Weld Position- Fillet Welds

Fillet Weld Positions The advantage of the fillet-welded joint is that it’s unnecessary to prepare the edges of the plates or sheets for welding. Double fillet-welded joints are an improvement over single-fillet joints because they can withstand loads from more than one direction. Three of the…blogs

STANDARDS FOR WELDING POSITIONS

Standards for Welding Positions: It is very important for the Weld Inspector to know the position, or location of a joint relative to the horizon, because it may determine what welding process, methods, and techniques can be used. Welding is usually easiest when the welder can…blogs

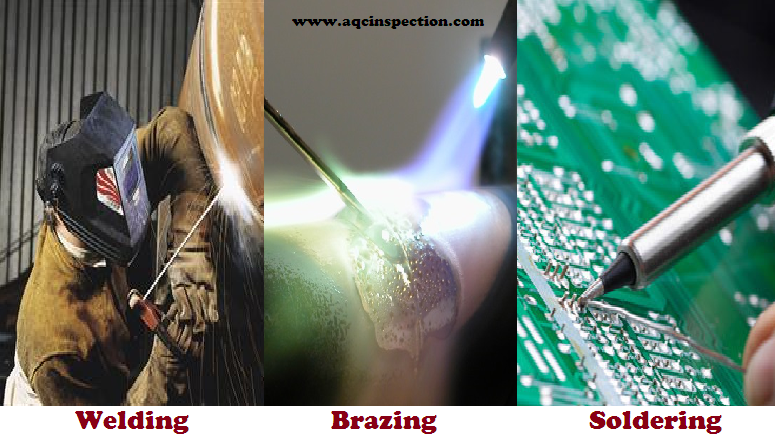

Types of Welding

Types of Welding Welding process involves joining of two metals and sometimes non-metals such as plastic There are many different types of weld, as below: Arc welding Atomic Hydrogen Welding ( AHW) Bare Metal Arc Welding (BMAW) Carbon Arc Welding (CAW) CAW-G—– Gas CAW-S—-Shielded CAW-T—–Twin Electro Gas Welding (EGW) …blogs, Training

Cast Iron and Its Types

What is a cast iron? Cast iron are ferrous alloys with greater than 2% carbon. They also contain small amounts of other materials such as silicon, sulphur, manganese, & phosphorous. In general it consists alloys of carbon & iron. They are the least expensive of all metals and…blogs