blogs

blogs

blogs

Recommendations for Welding

We would see about Recommendations for Welding of Structural Steel as per AWS D1.1 , 2020 revision Groove Weld: (Clause 4.4.1) Weld Length : shall be the width of the parts joined , perpendicular to the direction of compressive or tensile stress, Weld Size: Thickness of thinner…blogs

STANDARD SPECIFICATIONS FOR WELDING PROCEDURES

The sole purpose of welding procedures is to describe the details that are to be followed in the welding of specific materials or type of joint. The following is a list of standard specifications for welding procedures that are normally covered in welding procedures…blogs

Welding Standards-Positions for Welding Pipe

Positions for Welding Pipe For welding pipe in shops, power plants, oil refineries, and chemical plants for crude oil, gasoline, and natural gas, the same basic welding positions described previously are used. Flat Butt Weld Pipe Position…blogs

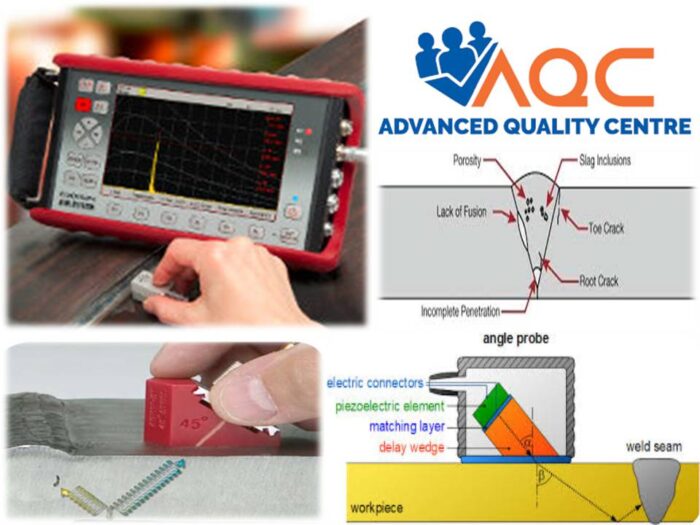

NONDESTRUCTIVE TESTING – Visual Inspection (VT)

The NDT (nondestructive testing) methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT Eddy Current Testing – ET (not used in field inspection) Acoustic Emission Testing – AET (not…blogs

What are the tasks to be considered during Welding Operations?

TASKS DURING WELDING OPERATIONS Welding inspection during welding operations should include all the audit parameters to verify that the welding is performed to the procedures. Such tasks may include the following: Quality Assurance Establish a quality assurance and quality control team with the welding organization. Quality control items to assess: …blogs

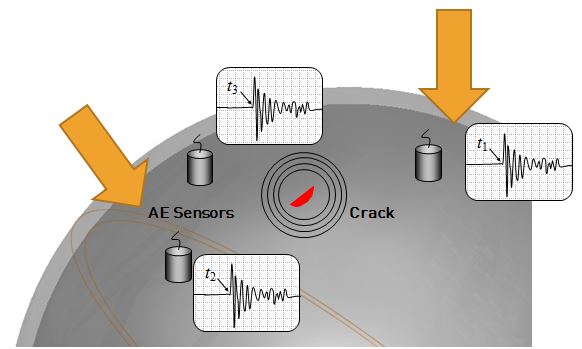

What is Acoustic emission testing?

ACOUSTIC EMISSION TESTING (AET) Acoustic Emission Test is a type of Non – Destructive Test method generally used for detecting and locating imperfections in mechanically loaded structures or components. Flaw origination and progression in a stressed component can be identified by acoustic emission test method.This…blogs

Preheating in Welding Procedure Specification

Preheating in Welding Procedure Specification: Preheating is the act of heating the base metal before starting to weld. It is considered very essential in high thickness materials, Cr-Mo Steels & HSLA High Speed Low Alloy steels, etc… Here we are going to answer the below topics …blogs

Welder Qualification Certificate

Welding Welding – Process of joining similar metals (or thermoplastic). By heating them to suitable temperature May or may not require pressure May or may not require Filler metal Brazing -Process of joining dis-similar metals. By Melting and pouring the filler metal and pouring…blogs