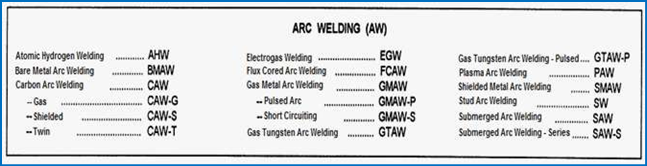

The welding processes are not the scope of this manual, specific for welding inspections. However, only for refreshing, the most common arc welding processes used in heavy and medium carbon and alloy steel manufacturing are:

SMAW: Shielded Metal Arc Welding – stick welding electrode;

GMAW: Gas Metal Arc Welding or MIG welding – solid wire or metal cored wire;

GTAW: Gas Tungsten Arc Welding or TIG welding – rod or solid wire.

SAW: Submerged Arc Welding – solid or tubular wire;

FCAW: Flux Cored Arc Welding – gas-shielded flux cored wire;

CAW: Carbon Arc Welding

PAW: Plasma Arc Welding

welding worktypes of welding processes

welding worktypes of welding processes

The steels commonly used in plate manufacturing, metallic structures and piping systems are covered by the specifications of ASTM, AISI, ASME, SAE, and API.

The specifications often refer to the same types of steels, although different restrictions on the chemical analysis and mechanical properties.

Commonly the most used materials for welded construction meet specifications conform to ASTM A 36, A 203, A 242, A 440, A 441, A 514, A 517, A 572 and A 588. For piping materials the main specifications are ASTM A 53, A 106, A 134, A 139, A 671, A 672 or A 691 or API 5L, 5LX, or 2H.

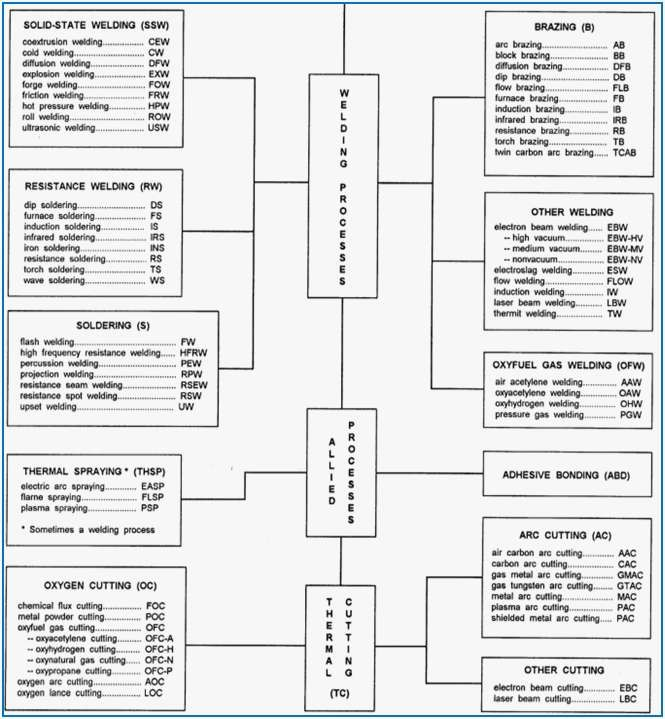

The table below gives a whole map of the different welding processes, very useful for welding inspection knowledge:

Arc welding

Welding Procedures

we provide standard specifications for welding procedures for all welding process and Brazing. We offer Welder Procedure Specification, Welder Certificate Renewal Process, Procedure Qualification Record, Welder Qualification Testing, welder Training and Welder qualification services in Coimbatore, Trichy, Salem, Erode, Chennai.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or