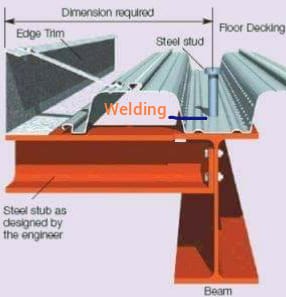

Studs are welded to steel structures for the purpose of anchoring. They are used as anchoring for Concretes, Insulation etc.,

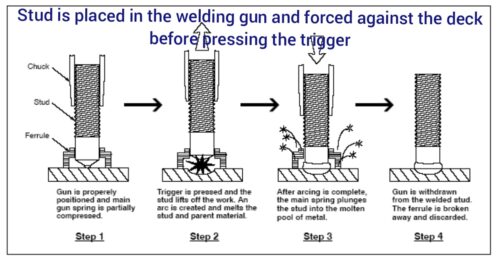

The studs may be threaded or headed bolts.The stud is inserted into the chuck of the welding gun. The stud tip is pressed against the base metal and trigger is pressed with continuous application of force.

An arc is produced between the stud tip and base metal. The metal melts due to arc temperature and metal fuses by application of a little pressure to the gun. Thus stud welding is done, without any additional filler metals.

A ceramic ferrule is placed around the stud tip to protect the weld pool from atmospheric gases, ferrule is broken after welding is made.

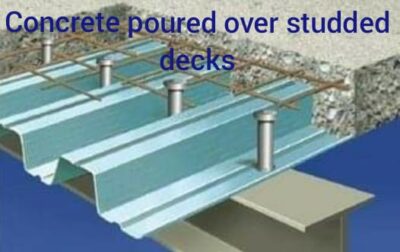

In civil construction, before pouring of concrete over the steel frame, the steel corrugated decks are placed on error the steel frame and studs are welded at frequent spacing.

It is essential for the structural quality engineer to check the integrity of the stud weld before pouring the concrete.

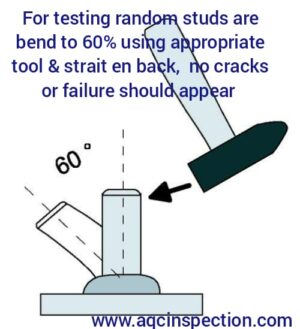

The bend test shall be done to check the integrity of weld.

The bend procedure involves bending few random welded studs to 60 degrees with a hammer and the straighten the studs back to original position. The Weld should show no failure due to bending.

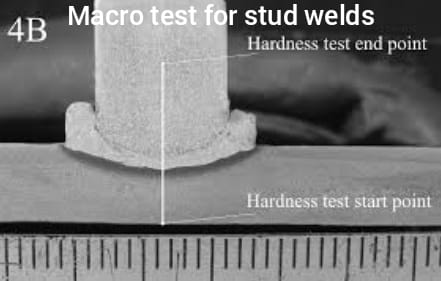

In addition macro etch test shall be done for

the stud welding procedure qualification.

The standard for arc stud welding of metallic materials refer the standard ISO 14555.

For guidance towards welding procedure preparation, qualification and inspections get in touch with us at https://aqcinspection.com/.

To about welding standards you can visit https://www.aws.org/