Introduction

In the realm of modern manufacturing and engineering, laser welding has emerged as a revolutionary technique, offering unparalleled precision and efficiency. By employing focused laser beams, this advanced process joins materials with exceptional accuracy, minimal heat-affected zones, and reduced distortion. In this comprehensive guide, we’ll delve into the world of laser welding, exploring its principles, applications, advantages, and challenges.

-

Laser Welding: Unveiling the Basics

In this section, we’ll provide a foundational understanding of what laser welding entails:

- The Laser Source: Delve into the different types of lasers used for welding, such as CO2 lasers, fiber lasers, and Nd:YAG lasers.

- Energy Concentration: Explain how laser beams are focused to generate intense heat at a specific spot on the material.

- Materials Suitable for Laser Welding: Discuss the types of materials that can be effectively joined using laser welding, including metals, plastics, and ceramics.

-

Mechanism and Process

Explore the intricate process of laser welding:

- Absorption and Reflection: Detail how materials interact with laser energy, including absorption and reflection phenomena.

- Melting and Solidification: Explain the stages of material transformation during laser welding, from melting to solidification.

- Keyhole Formation: Discuss the concept of the “keyhole” – a vapor-filled cavity formed during laser welding, crucial for deep penetration welds.

-

Types of Laser Welding

Dive into the diverse approaches to laser welding:

- Conduction Welding: Describe conduction welding, ideal for shallow welds on thin materials.

- Deep Penetration Welding: Explain the process of deep penetration welding, suitable for thicker materials and high-speed welding.

- Laser Beam Welding: Explore how laser beam welding achieves seam welds by melting and fusing edges together.

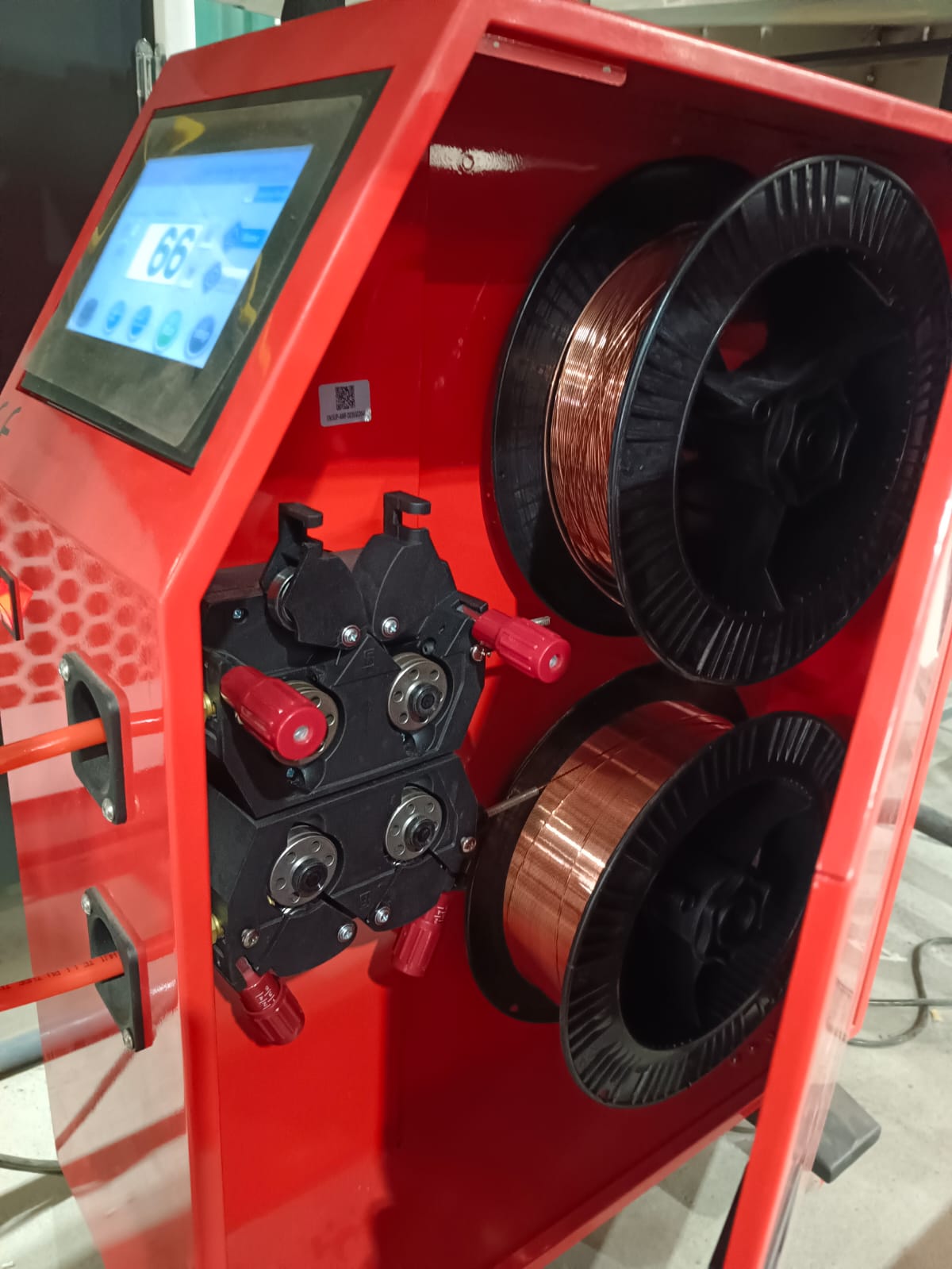

- Laser Hybrid Welding: Introduce hybrid welding, which combines laser welding with other welding techniques for enhanced efficiency.

-

Applications of Laser Welding

Highlight the wide-ranging applications of laser welding across industries:

- Automotive Industry: Discuss how laser welding is used for manufacturing car bodies, exhaust systems, and engine components.

- Aerospace Sector: Explore its role in creating lightweight and durable aircraft components.

- Electronics and Microtechnology: Explain how laser welding enables intricate connections in microelectronics.

- Medical Devices: Showcase how laser welding ensures precision in medical device manufacturing.

-

Advantages and Disadvantages

Evaluate the pros and cons of laser welding:

- Advantages: Cover benefits like high precision, minimal distortion, reduced heat input, and suitability for automation.

- Disadvantages: Discuss potential drawbacks such as equipment costs, material limitations, and the need for skilled operators.

-

Challenges and Future Trends

Explore the challenges faced by laser welding technology and its future directions:

- Joint Design and Fit-up: Address the importance of proper joint preparation for successful laser welding.

- Quality Control: Discuss techniques for ensuring weld quality and integrity.

- Advancements in Laser Technology: Touch on emerging trends in laser sources, beam delivery, and process monitoring.

Conclusion

Laser welding stands as a testament to human ingenuity, offering unprecedented precision and versatility in the field of material joining. From its fundamental principles to its multifaceted applications, this guide has shed light on the brilliance of laser welding. As technology continues to evolve, laser welding is poised to play an even more significant role in shaping the future of manufacturing and engineering.

For more detailed definitions , refer the standard AWS A3.0 ,or feel free to contact us

https://aqcinspection.com/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or