blogs

blogs

blogs

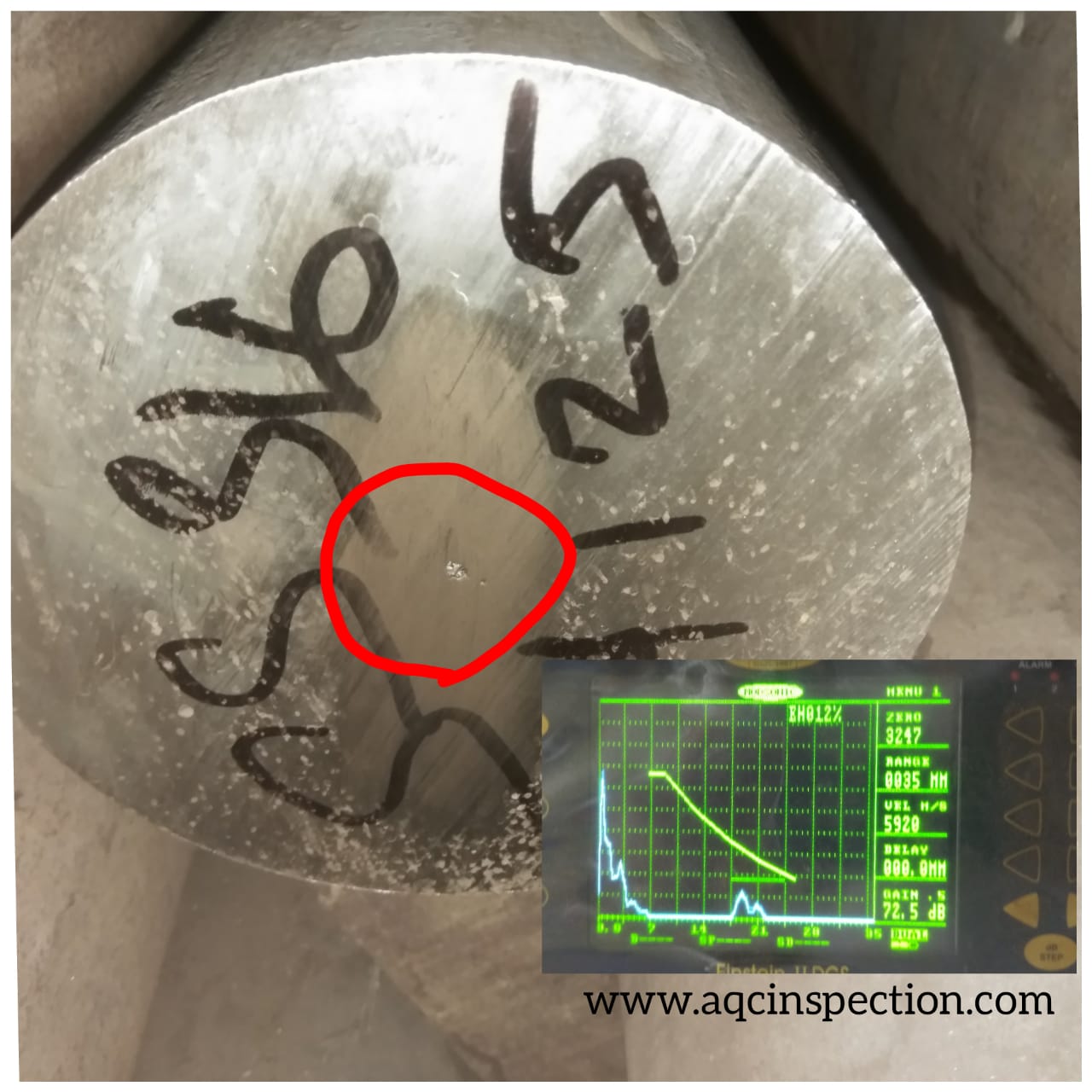

Sensitivity setting for ultrasonic testing as per ISO 17640

Range and Sensitivity Setting for Ultrasonic testing Setting of range and sensitivity shall be carried out prior to each testing in according to this procedure. The temprture difference between the time of range and sensitivity setting and time of test should be within ± 15°C. Checks…blogs

Ultrasonic testing Couplants

A study on the couplant effects in contact ultrasonic testing. The primary purpose of a couplant is to provide a suitable sound path between the transducer and the test surface.Ultrasonic Testing couplants usage can be seen here A couplant must effectively wet or totally…blogs