blogs

blogs

blogs

Mechanical Properties

The mechanical properties of a material are those properties that involve a reaction to an applied load. The mechanical properties of metals determine the range of usefulness of a material and establish the service life that can be expected. Mechanical properties are also used to…blogs

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. Forging is often classified according to the temperature: “cold”, “warm”, or “hot” forging. Forged parts can range in weight from less than a kilogram to 580 metric tons. Forged parts usually…blogs

Hardness Test- types

Rockwell Superficial Hardness Test: The Rockwell Superficial Hardness Tester is used to test thin materials, lightly carburized steel surfaces, or parts that might bend or crush under the conditions of the regular test. This tester uses the same indenters as the standard Rockwell tester but…blogs

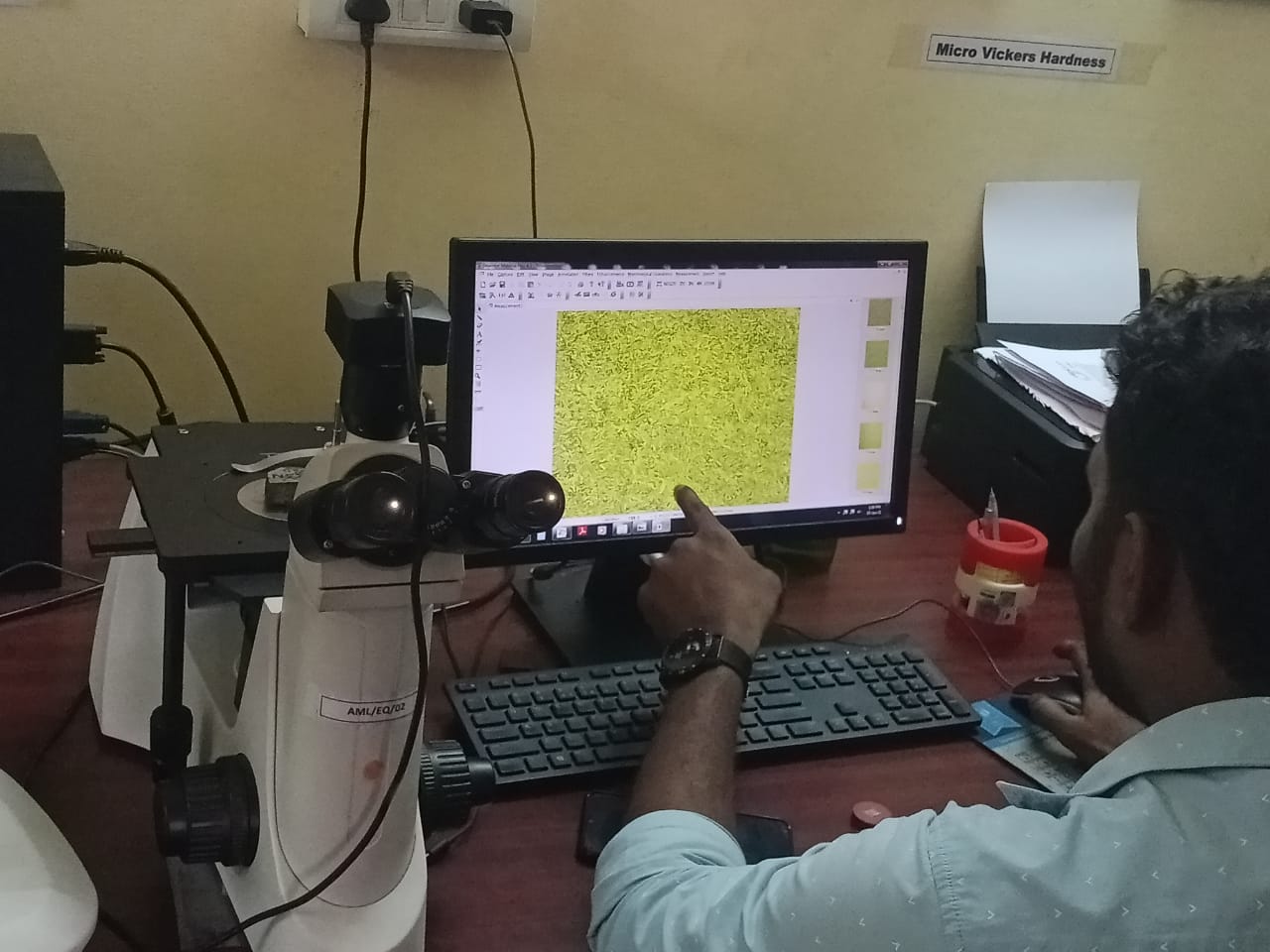

Hardness Testing

Hardness Testing: Hardness is the resistance of a material to localized deformation. The term can apply to deformation from indentation, scratching, cutting or bending. In metals, ceramics and most polymers, the deformation considered is plastic deformation of the surface. For elastomers and some polymers, hardness is…blogs

NDT – Few Other Methods

Here are some rarely used NDT – Few Other Methods 1. Eddy Current Testing – ET: Eddy-current inspection uses electromagnetic induction to detect flaws in conductive materials. A circular coil carrying current is placed in proximity to the test specimen (electrically conductive). The alternating current in…blogs

Recommendations for Welding

We would see about Recommendations for Welding of Structural Steel as per AWS D1.1 , 2020 revision Groove Weld: (Clause 4.4.1) Weld Length : shall be the width of the parts joined , perpendicular to the direction of compressive or tensile stress, Weld Size: Thickness of thinner…blogs

Welding Standards-Positions for Welding Pipe

Positions for Welding Pipe For welding pipe in shops, power plants, oil refineries, and chemical plants for crude oil, gasoline, and natural gas, the same basic welding positions described previously are used. Flat Butt Weld Pipe Position…blogs

Weld Position- Fillet Welds

Fillet Weld Positions The advantage of the fillet-welded joint is that it’s unnecessary to prepare the edges of the plates or sheets for welding. Double fillet-welded joints are an improvement over single-fillet joints because they can withstand loads from more than one direction. Three of the…blogs