GTAW Welding on Stainless steel – SS

- Produces very strong/tough weld compared to other process

- Slow process

- Good appearance

- Mostly used for Root and hot pass & Low thickness material

- Low heat input process

- More controlled process, but requires good welder skills .

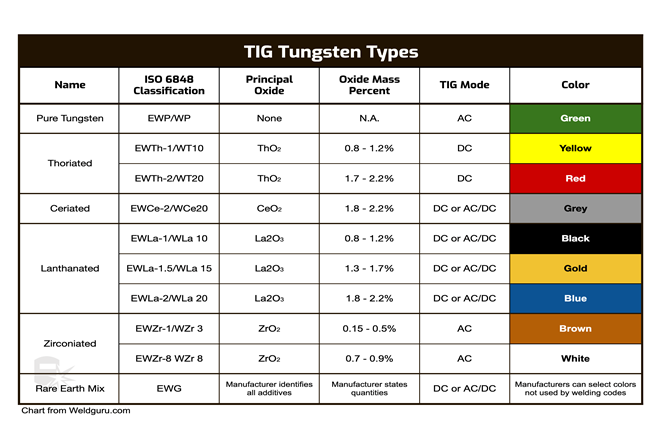

- Electrode – Tungsten Rod (most common is 2% thoriated)

- AWS Filler Specification : AWS A5.9

- Example: ER 209, ER308Si, ER309L, ER316L, ER410

- For CS to SS welding use any of ER 309, ER309LSi, ER 310, ER312

- Use proper purging for Butt weld , where root side is open on the other side before welding .

GMAW / FCAW Welding on Stainless Steel

- High speed, high deposition rate.

- Suitable for Thick materials , better look than SMAW

- AWS Specification :

- AWS A5.9 – Solid wire

- AWS A5.20- Flux Cored wire

- AWS A5.22 – Metal Cored wire

Shielding Gas for GMAW-Solid Wire:

- Normally shielding gases like Pure Argon are used .Ar+ 1-2% O2. Ar+ 1-2% CO2 and Ar+18-33% He+1-2% CO2 are good choices for spray transfer mode of solid wire.

- However 90% He+7.5% Ar+2.5% CO2 (the most popular one)

- Ar+2% O2 and Ar+25% CO2 are used in short circuiting transfer mode.

Shielding Gas for GMAW-Metal Cored Wire:

- shielding gases like Ar+1-2% O2 and Ar+1-2% CO2 are good choices for spray transfer mode of Metal Cored Wire.

FCAW : CO2 or Ar + CO2

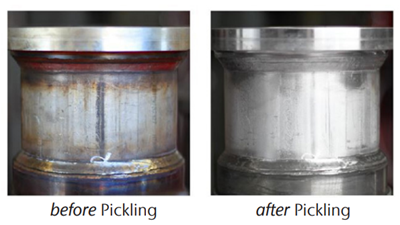

Pickling

- Process of removing the oxide layers form the surface

- Due to heat , burnt – oxide layers are visible on the weld and HAZ areas

- Where the chromium level has been reduced on the surface .

- Pickling Solution : hydrochloric acid and sulfuric acid .

Passivation

- Passivation is the process of creating the passive chromium oxide layer over the surface.

- The passive oxide layer is essential to prevent corrosion ,

- Passivation Solution : generally Nitric acid

- Nitric Acid is a solution which dissolves all iron components and trace material , and also it is a strong oxidizing unit to make the chromium oxide layer

- Nowadays Pickling gel or Solution does both Pickling and Passivation simultaneously.

- Pickling gel may be mixture of Nitric acid, Sulfuric acid, Phosphoric acid & hydrofluoric acid.

For more training or certifications for welding operator , please feel free to contact us through [email protected], [email protected],

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or