Multiple WPSs and PQRs

Several WPSs can be derived from a single PQR. For example, a 1G plate PQR can support WPSs for 2G, 3G, 4G, pipe 5G, and 6G, as long as other parameters remain the same. Conversely, a single WPS can cover multiple PQRs. For instance, a WPS might cover a thickness range of 1.6 mm to 32 mm if there are PQRs for the ranges 1.6 to 4.8 mm and 4.8 to 32 mm.

Weld Orientation

- Plate Groove Positions: 1G, 2G, 3G, 4G

- Pipe Groove Positions: 1G, 2G, 5G, 6G

- Plate Fillet Positions: 1F, 2F, 3F, 4F

- Pipe Fillet Positions: 1F, 2F, 2FR, 4F, 5F

- 1F: 0° to 30°

- 2F: +15° to -10° with respect to 45°

- 4F: 0° to 125°

- 3F: 125° to 235°

Base Metal Classification

P numbers are based on composition, weldability, and mechanical properties. Group numbers categorize metals within P numbers for procedure qualification when notch toughness requirements are specified. However, base metals cannot be substituted indiscriminately.

Conclusion

In summary, the qualification and documentation of Welding Procedure Specifications (WPS) and Procedure Qualification Records (PQR) are critical steps in ensuring the quality and reliability of weldments for their intended applications. WPSs provide clear guidance to welders and define the essential variables for welding processes, while PQRs record the welding data and test results to confirm that the required properties are achieved. The ability to derive multiple WPSs from a single PQR, and to cover multiple PQRs with a single WPS, offers flexibility and efficiency in welding operations. This comprehensive approach ensures that weldments meet the necessary standards and perform as expected in their designated roles.

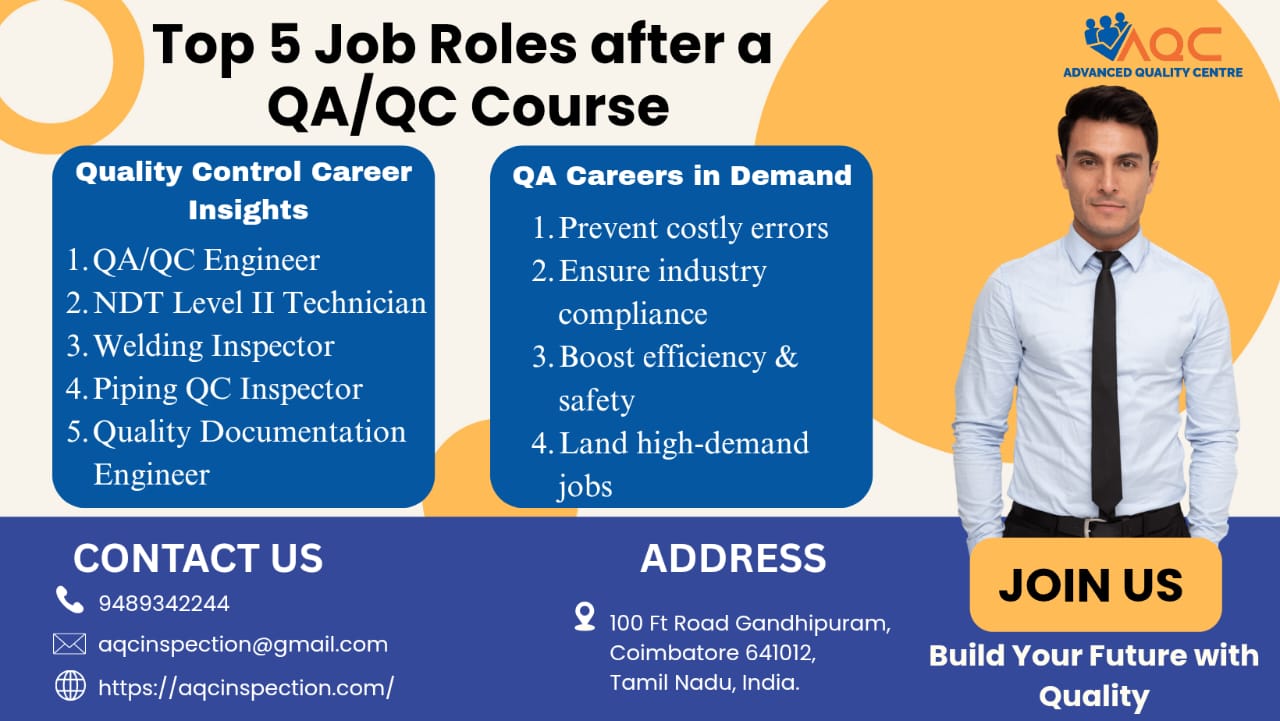

For more training or certifications for welding operator , please feel free to contact us through [email protected], [email protected], https://aqcinspection.com .

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

https://ndtcenter.blogspot.com