Training

Training

blogs

Pipe Line Isometric Drawings and P & ID Drawings

Pipe Isometrics : Are drawings which shows details of Process pipe lines in a single line presentation , with details of pipes, pipe connections ( valves, flanges, nipples, reducers, end cap, elbow, etc), along with the dimensions and direction of pipe line. Example of a…blogs

NDT Methods Selection

NDT Method Selection: The NDT (nondestructive testing) methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT Eddy Current Testing – ET (not used in field inspection) Acoustic Emission Testing –…blogs

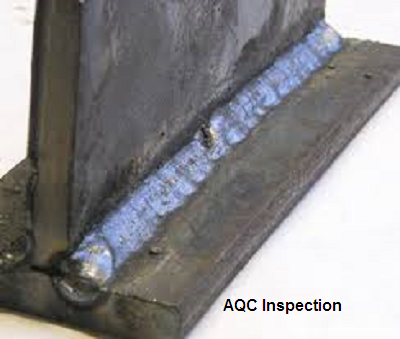

Concepts of Welding Defects and Discontinuities

Welding defects can be classified as structural discontinuities and consist of: porosity, slag inclusions, lack of fusion, cracks, etc. Porosity is gas pockets or voids in the weld metal which are free of any solid materials, such as It is formed as a result…blogs

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2 This blog here answers your questions about: What is the tolerance for Fillet weld sizes as per AWS D1.1 ? What is the weld size tolerance? What is the required fillet weld size for structures…blogs

NDT Course fees

NDT Course fees depends on the type of NDT Course Selected, such a number of methods and the International standard chosen for the certification The Average course fees for General NDT course will be Rs.17500, This course fees Rs.17500 is for ASNT Level II Certification course…blogs

Fillet Weld Types

Fillet Weld Types: The single-fillet-welded T-joints are indicated from both the arrow side and the other side. The symbol for a double fillet-welded T-joint is also Note that the assembly of two T-joints welded pieces involves four fillet welds represented by two double-fillet-weld symbols.blogs

Standards and Specifications for welding

WELDING INSPECTOR KNOWLEDGES: The Welding Inspector must be a high skilled technician or engineer with a good knowledge of general industry manufacture, materials, quality systems, inspection procedures and Standards and Specifications for welding as: Standard organizations as ASTM, SAE, AISI, AWS, ASME and other institutions; …blogs

WELDING ELECTRODES AND PREHEAT REQUIREMENTS

The procedure requirements for welding electrodes and preheating temperatures are as follows: Welding must be done with the same process (SMAW or FCAW) used for qualification If the operator has qualified on any of the steel permitted (ASTM A36 and A588), that same operator…blogs