blogs

blogs

blogs

NDT Course fees

NDT Course fees depends on the type of NDT Course Selected, such a number of methods and the International standard chosen for the certification The Average course fees for General NDT course will be Rs.17500, This course fees Rs.17500 is for ASNT Level II Certification course…blogs

NDT – Few Other Methods

Here are some rarely used NDT – Few Other Methods 1. Eddy Current Testing – ET: Eddy-current inspection uses electromagnetic induction to detect flaws in conductive materials. A circular coil carrying current is placed in proximity to the test specimen (electrically conductive). The alternating current in…blogs

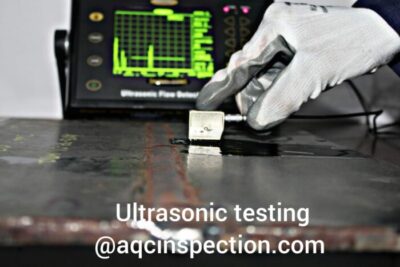

Non destructive Testing (NDT)- Common Methods

Non destructive Testing (NDT)- Common Methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT 1. Visual Inspection – VT: Visual inspection after welding is very useful in evaluating quality, even if…blogs

Welding Standards-Positions for Welding Pipe

Positions for Welding Pipe For welding pipe in shops, power plants, oil refineries, and chemical plants for crude oil, gasoline, and natural gas, the same basic welding positions described previously are used. Flat Butt Weld Pipe Position…blogs

Equipments and materials for NDT lab set up

Equipments and materials for NDT lab set up Radiography Testing: 1) X-Ray tube head -450 kV capacity ( only if construction of a exposure room with approval from government is possible) 2) RT Films (D4 ) 3) lead screen 0.125mm, 0.25 mm 4) Film casettes 5) set of IQI -wire…blogs, Training

Acceptance Criteria for Liquid Penetrant Testing -LPT

Acceptance Criteria for Liquid Penetrant Testing -LPT as per ASME , AWS and API standards Liquid penetrant testing simply called as PT. Sometimes Dye Penetrant Testing is a surface defect detection NDT method and is more sensitive to all kind of surface defects, such as…blogs

Non Relevant Ultrasonic Indications

Non relevant Ultrasonic Indications can usually be identified as one of the following: Electrical Interference Interference form the transducer (search unit) Interference form the surface of the specimen Interference caused by mode conversion of the sound beam Interference caused by the shape of the…blogs

Standards for Piping Design and Inspection

Standards for Piping Design and Inspection: The original ASME B31 Code for Pressure Piping was first introduced in 1935 as the single document for piping design. In 1955, ASME began to separate the code into sections…blogs