blogs

blogs

blogs

WELDING SYMBOLS

Elements of Welding Symbols: The first concepts the Welding Inspector must understand very well, are the welding symbols and how to interpret them on drawings. The reference line of the welding symbol, as shown below, is used to designate the type of weld to be…blogs

Hardness Testing

Hardness Testing: Hardness is the resistance of a material to localized deformation. The term can apply to deformation from indentation, scratching, cutting or bending. In metals, ceramics and most polymers, the deformation considered is plastic deformation of the surface. For elastomers and some polymers, hardness is…blogs

NDT – Few Other Methods

Here are some rarely used NDT – Few Other Methods 1. Eddy Current Testing – ET: Eddy-current inspection uses electromagnetic induction to detect flaws in conductive materials. A circular coil carrying current is placed in proximity to the test specimen (electrically conductive). The alternating current in…blogs

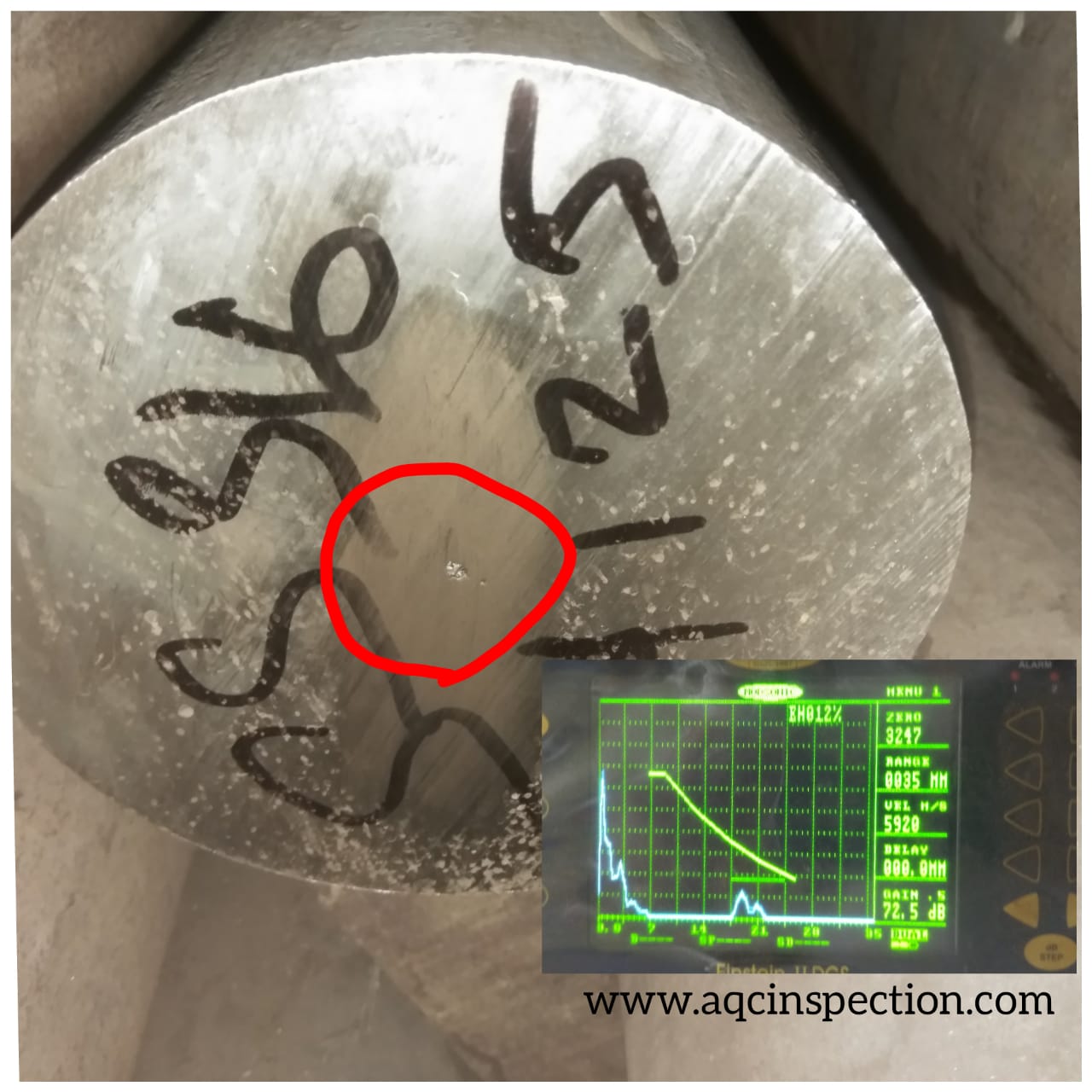

Non destructive Testing (NDT)- Common Methods

Non destructive Testing (NDT)- Common Methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT 1. Visual Inspection – VT: Visual inspection after welding is very useful in evaluating quality, even if…blogs

Welding Standards-Positions for Welding Pipe

Positions for Welding Pipe For welding pipe in shops, power plants, oil refineries, and chemical plants for crude oil, gasoline, and natural gas, the same basic welding positions described previously are used. Flat Butt Weld Pipe Position…blogs

NONDESTRUCTIVE TESTING – Visual Inspection (VT)

The NDT (nondestructive testing) methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT Eddy Current Testing – ET (not used in field inspection) Acoustic Emission Testing – AET (not…blogs

Equipments and materials for NDT lab set up

Equipments and materials for NDT lab set up Radiography Testing: 1) X-Ray tube head -450 kV capacity ( only if construction of a exposure room with approval from government is possible) 2) RT Films (D4 ) 3) lead screen 0.125mm, 0.25 mm 4) Film casettes 5) set of IQI -wire…blogs, Training

Acceptance Criteria for Liquid Penetrant Testing -LPT

Acceptance Criteria for Liquid Penetrant Testing -LPT as per ASME , AWS and API standards Liquid penetrant testing simply called as PT. Sometimes Dye Penetrant Testing is a surface defect detection NDT method and is more sensitive to all kind of surface defects, such as…blogs