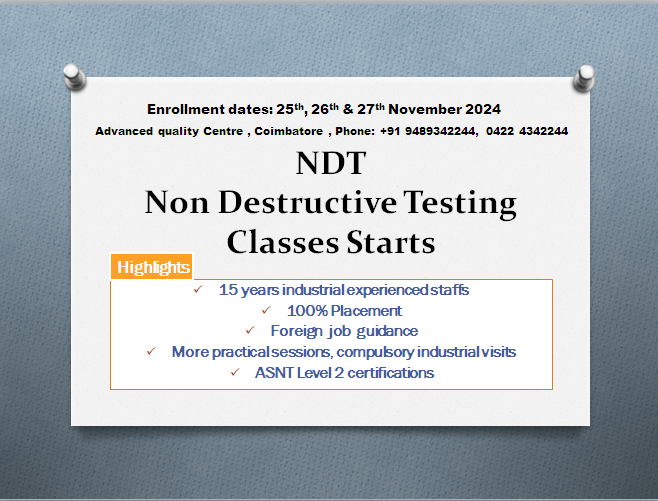

Training

Training

blogs, Job Assistance, Training

Scope of NDT

Dear students and engineers , this article will give details of scope of NDT , where it is applicable and what is the salary range for working in Non Destructive Testing Technologies. Scope of NDT : Non Destructive Testing shortly called as NDT has scope in…blogs

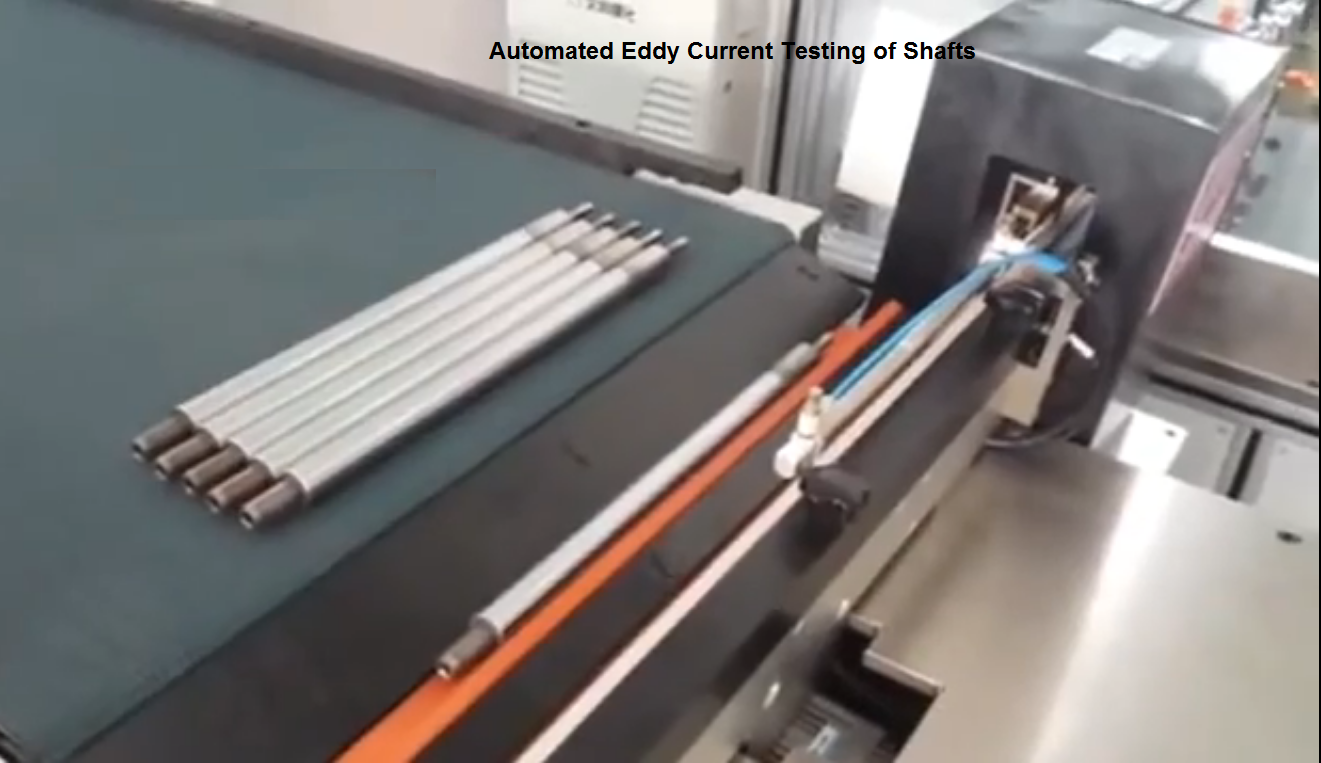

NDT Accessories

Non-Destructive Testing (NDT) accessories are essential components that support NDT techniques used to evaluate the integrity and properties of materials or structures without causing damage. NDT is widely used in industries like aerospace, construction, manufacturing, oil and gas, and more. The accessories used in…blogs

Helium Leak testing

Helium leak testing is a critical procedure used to identify and measure the presence of helium leaks in various systems, often employed in aerospace, industrial, and manufacturing applications due to helium’s small atomic size and inert properties. Key Concepts in Helium Leak Testing: Helium as…blogs

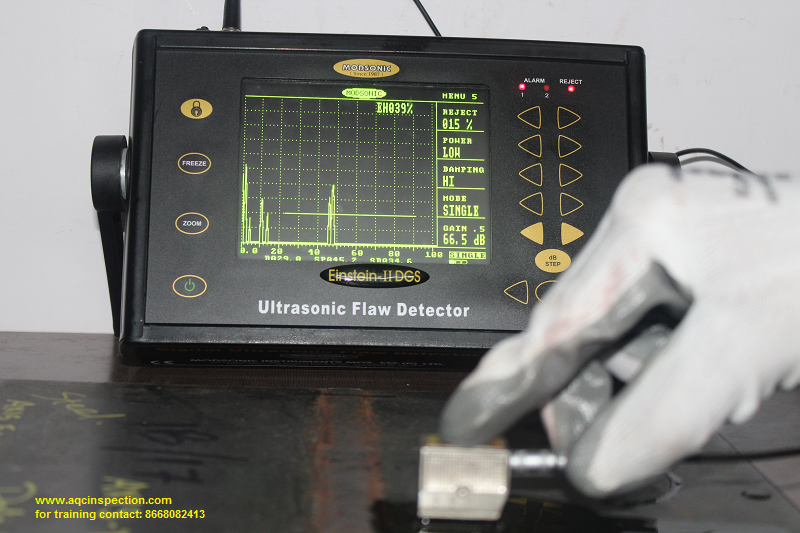

Probe Selection for Ultrasonic Scanning of welds

Ultrasonic testing involves sound waves , that is otherwise called as vibration traveling inside a medium , the ultrasonic sound waves gets reflected back whenever there is change in a material ( different acoustic impedance ) , the reflection is more when the sound…blogs, Job Assistance, Training

Mastering Mechanical Quality Control -QC Course

Quality control – QC course is a crucial aspect of mechanical engineering, ensuring that products and systems meet the required standards and specifications. Introduction to Quality Control: Understanding the importance of quality control in mechanical engineering. Historical perspective and the evolution of quality control. …blogs

Navigating the Future of NDT Courses : Trends and Innovations

Introduction: In the ever-evolving landscape of Non-Destructive Testing (NDT), staying current with the latest trends and innovations is crucial for professionals and students alike. NDT courses plays a pivotal role in ensuring the safety and integrity of structures, components, and materials across various industries. As…blogs

QC course for Mechanical Engineers

Part time QC course for Mechanical Engineers Quality Control and Quality Assurance Department is a satisfying career field, and is one among the core job. Quality Assurance and Quality Control nowadays had become essential in all industries, particularly in manufacturing and construction industries. It may include…blogs