Non Destructive Testing,NDT on Shafts is considered essential , because the shafts are mostly made as load bearing structures, any defects such as cracks will propagate more during acting of load and eventually will cause failure.

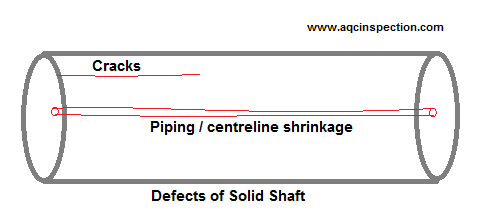

The most possible defects in shafts are Cracks and Pipes , which is shown below

The Non Destructive methods preferred for defect detection on raw material shafts are Ultrasonic Testing, Magnetic Particle testing / Eddy Current Testing / Magnetic Flux Leakage method.

We have not discussed about other NDT methods such as Liquid Penetrant testing & Radiographic testing because for raw material inspection. These methods will be cost effective for raw material testing ( i.e. most costly and labor intensive, also there is possibility of missing out the cracks in radiography testing due to orientation of crack )

The Defect wise identification method is given as below ,

- Internal Defect ( Piping ) – Ultrasonic Testing

- Surface Defects (C racks) – Magnetic Particle Testing / Eddy Current Testing / Magnetic Flux Leakage

Applicable Materials:

Ultrasonic Testing is possible on any materials and of any thickness, but conventional ultrasonic method is effective only on thickness greater than 8 mm thickness.

Magnetic Particle testing & Magnetic Flux leakage method is suitable only on ferromagnetic materials (example Steel, Martensitic or ferritic stainless steel, cast iron etc.).

Eddy Current test is possible on both ferromagnetic and Non Ferromagnetic steels, but on conductive materials only.

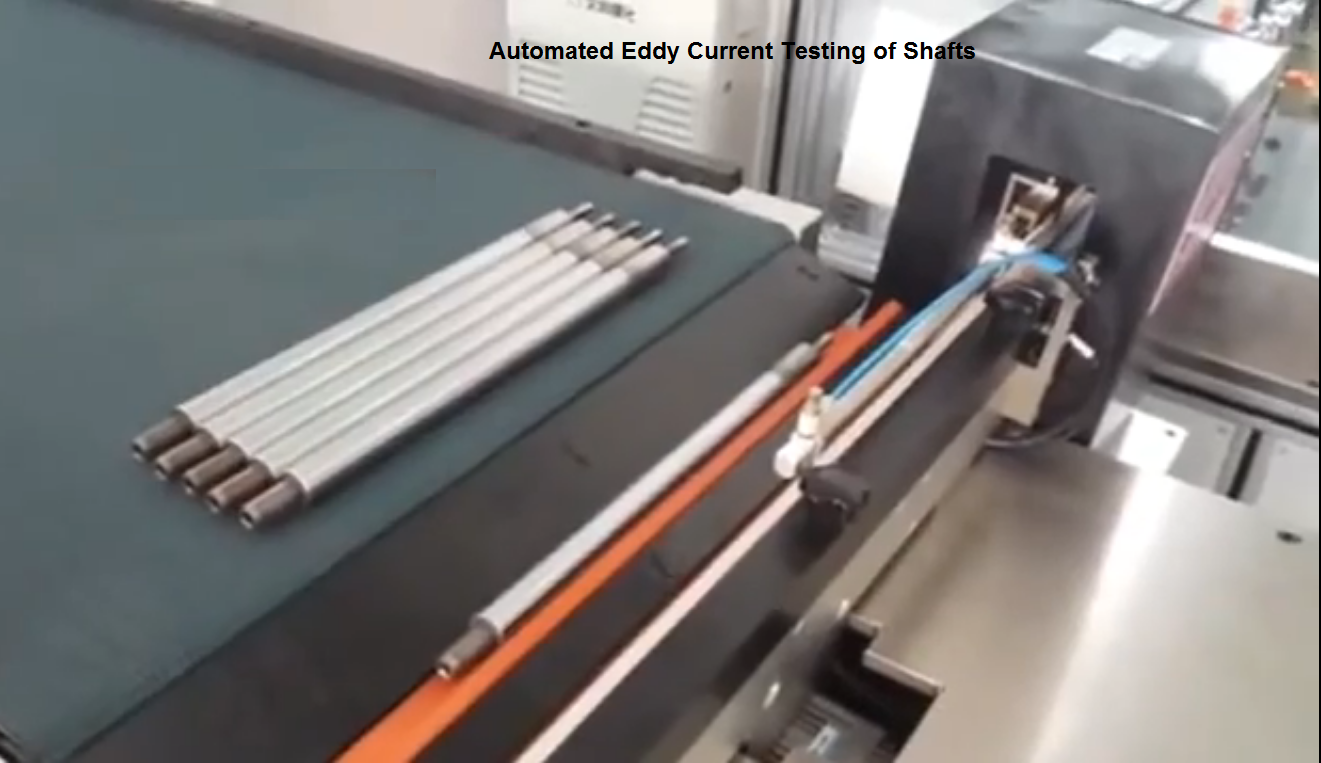

Automated Crack Detection Methods:

For mass inspection of NDT on shafts, NDT such as Eddy Current Testing and Magnetic Flux Leakage method can be automated.

Video link : https://www.bkneddy.com/resources/rotating-eddy-current-flaw-detection-system.html

For more details on NDT methods , training on NDT testing , ndt courses , ndt procedure qualification, certification and equipment details please feel to call us on mobile: +918668082413 of visit http://aqcinspection.com/ .

Advanced Quality Centre stands out to be best NDT training institute and NDT service provider in south India and team with most experienced engineers in the field .