blogs

blogs

blogs

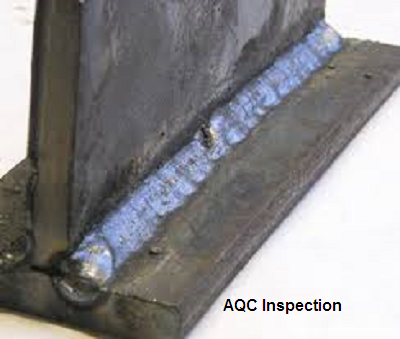

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2 This blog here answers your questions about: What is the tolerance for Fillet weld sizes as per AWS D1.1 ? What is the weld size tolerance? What is the required fillet weld size for structures…blogs

Fillet Weld Types

Fillet Weld Types: The single-fillet-welded T-joints are indicated from both the arrow side and the other side. The symbol for a double fillet-welded T-joint is also Note that the assembly of two T-joints welded pieces involves four fillet welds represented by two double-fillet-weld symbols.blogs

Standards and Specifications for welding

WELDING INSPECTOR KNOWLEDGES: The Welding Inspector must be a high skilled technician or engineer with a good knowledge of general industry manufacture, materials, quality systems, inspection procedures and Standards and Specifications for welding as: Standard organizations as ASTM, SAE, AISI, AWS, ASME and other institutions; …blogs

WELDING ELECTRODES AND PREHEAT REQUIREMENTS

The procedure requirements for welding electrodes and preheating temperatures are as follows: Welding must be done with the same process (SMAW or FCAW) used for qualification If the operator has qualified on any of the steel permitted (ASTM A36 and A588), that same operator…blogs

Mechanical Properties

The mechanical properties of a material are those properties that involve a reaction to an applied load. The mechanical properties of metals determine the range of usefulness of a material and establish the service life that can be expected. Mechanical properties are also used to…blogs

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. Forging is often classified according to the temperature: “cold”, “warm”, or “hot” forging. Forged parts can range in weight from less than a kilogram to 580 metric tons. Forged parts usually…blogs

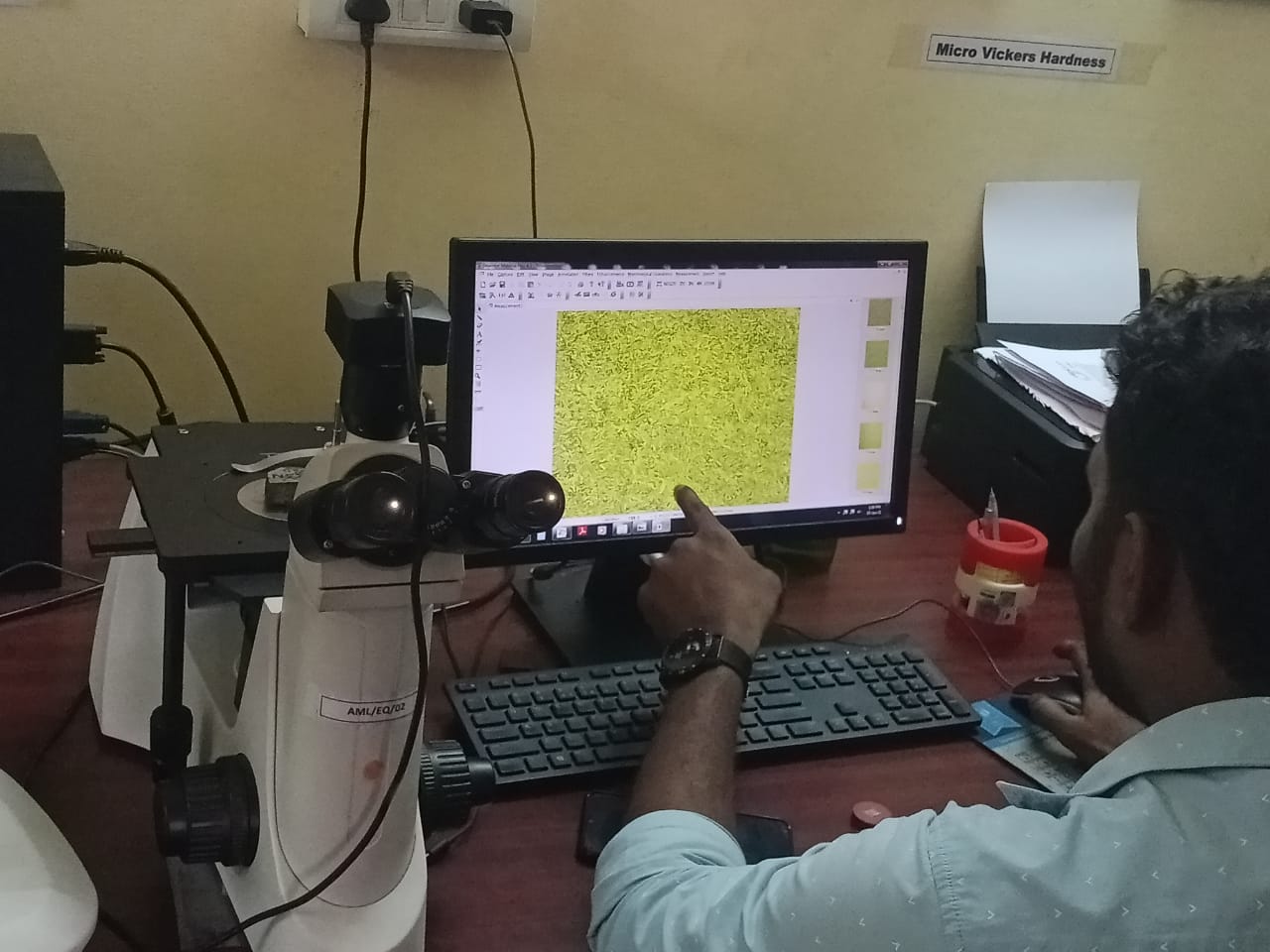

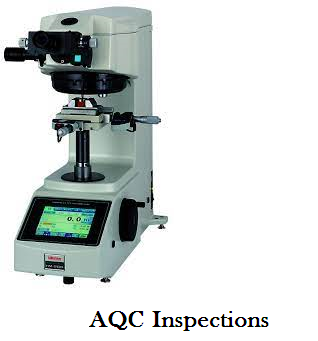

Hardness Test- types

Rockwell Superficial Hardness Test: The Rockwell Superficial Hardness Tester is used to test thin materials, lightly carburized steel surfaces, or parts that might bend or crush under the conditions of the regular test. This tester uses the same indenters as the standard Rockwell tester but…blogs

Weld symbols location

1.1. Location of the Weld with Respect to Joint: a.Arrow Side. Welds on the arrow side of the joint are shown by placing the weld symbols on the side of the reference line toward the reader.blogs