blogs

blogs

blogs

STANDARDS FOR WELDING POSITIONS

Standards for Welding Positions: It is very important for the Weld Inspector to know the position, or location of a joint relative to the horizon, because it may determine what welding process, methods, and techniques can be used. Welding is usually easiest when the welder can…blogs

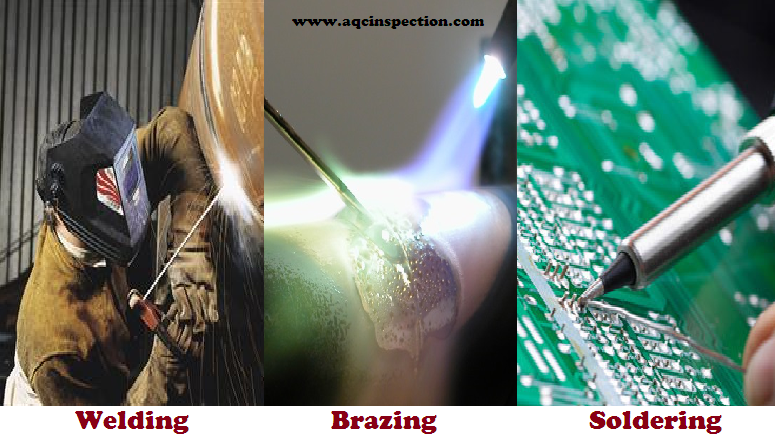

Types of Welding

Types of Welding Welding process involves joining of two metals and sometimes non-metals such as plastic There are many different types of weld, as below: Arc welding Atomic Hydrogen Welding ( AHW) Bare Metal Arc Welding (BMAW) Carbon Arc Welding (CAW) CAW-G—– Gas CAW-S—-Shielded CAW-T—–Twin Electro Gas Welding (EGW) …blogs

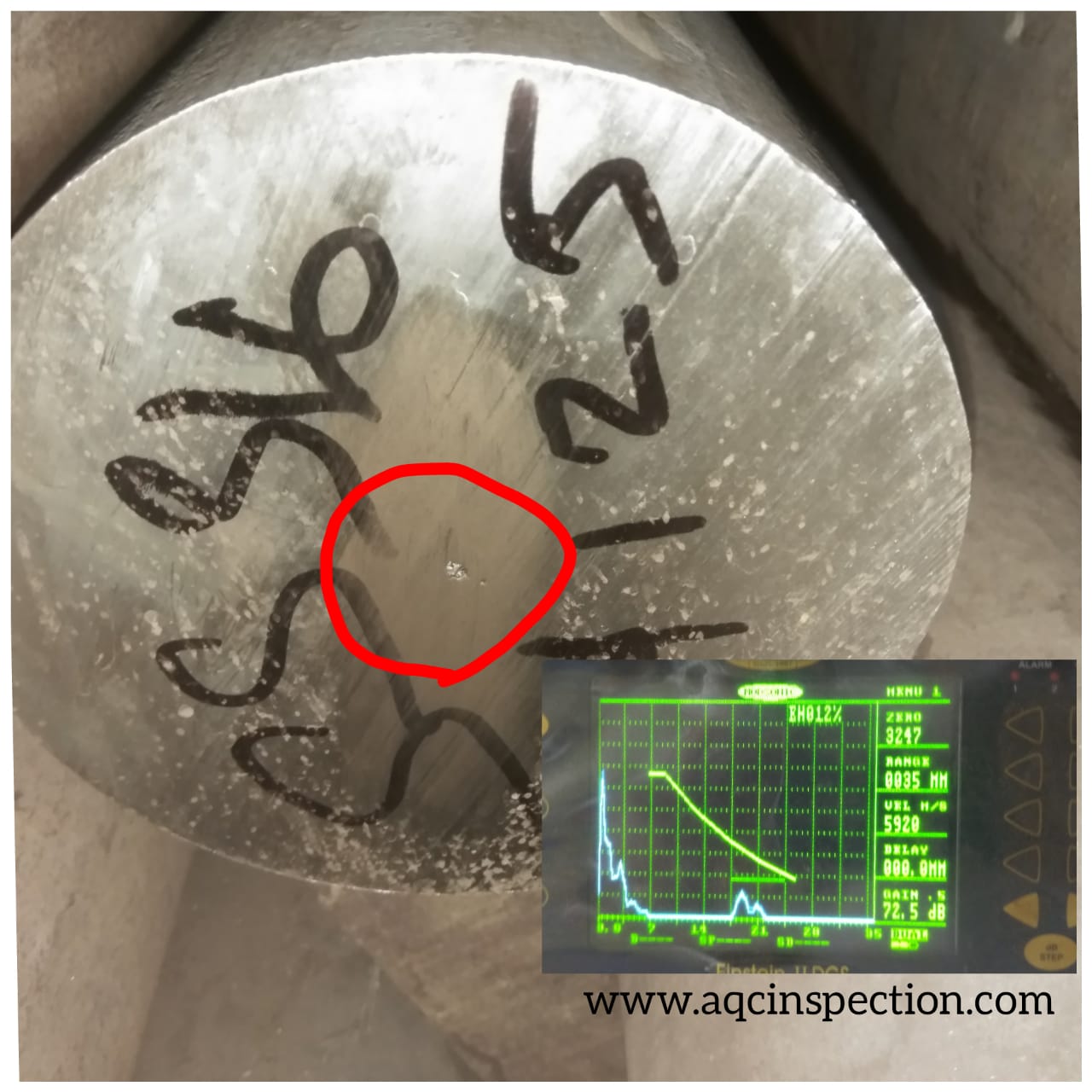

Acceptance Criteria for Ultrasonic Testing

How to interpret Acceptance Criteria for Ultrasonic Testing as per AWS D1.1 The Requirements of Ultrasonic Flaw detector equipment as per AWS D1.1 Structural Steel Welding code is given below: Equipment: The ultrasonic equipment’s shall be pulse echo type ‘A’ scan suitable for use with transducers…blogs

What are the tasks to be considered during Welding Operations?

TASKS DURING WELDING OPERATIONS Welding inspection during welding operations should include all the audit parameters to verify that the welding is performed to the procedures. Such tasks may include the following: Quality Assurance Establish a quality assurance and quality control team with the welding organization. Quality control items to assess: …blogs

Sensitivity setting for ultrasonic testing as per ISO 17640

Range and Sensitivity Setting for Ultrasonic testing Setting of range and sensitivity shall be carried out prior to each testing in according to this procedure. The temprture difference between the time of range and sensitivity setting and time of test should be within ± 15°C. Checks…blogs