Failure investigation often uncovers facts that lead to changes in design, manufacturing, or operating practice, which will eliminate similar failures in the future. Failures of insignificant parts can also lead to advances in knowledge and should be done objectively, as with a large structure.

The following four areas of interest should be investigated to determine the cause of weld failure or weld defects and the interplay of factors involved:

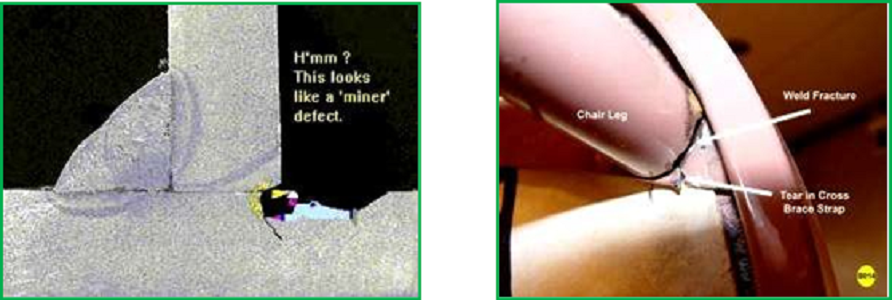

- Initial observation. The detailed study by visual inspection should be made at the failure site as quickly as Photographs should be taken, preferably in color, of all parts, structures, failure surfaces, fracture texture appearance, final location of component debris, and all other factors.

- Background data. All information concerning specifications, drawings, component design, fabrication methods, welding procedures, weld schedules, repairs in and during manufacturing and in service, maintenance, and service use. Attention should be given to environmental details, including operating temperatures, normal service loads, overloads and cyclic loading.

- Laboratory studies. Studies should also be made microscopically in those situations in which it would lead to additional information. Fracture surfaces can be extremely important. Any other defects in the structure that are apparent, even though they might not have contributed to the failure, should also be noted and investigated.

- Failure assumptions. It is important to know what specific things did not happen or what evidence did not appear to help determine what happened. The data should be tabulated and the actual Weld defects should be synthesized to include all available evidence.

Obs.: Failure cause can usually be classified in one of the following three classifications:

- Failure due to faulty design or misapplication of

- Failure due to improper processing or improper

- Failure due to deterioration during

we provide standard specifications for welding procedures for all welding process and Brazing. We offer Welder Procedure Specification, Welder Certificate Renewal Process, Procedure Qualification Record, Welder Qualification Testing, welder Training and Welder qualification services in Coimbatore, Trichy, Salem, Erode, Chennai.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

https://ndtcenter.blogspot.com