Brazing Process

We Advanced Quality Centre, AQC School of Welding Excellence , train Welders , Brazing operators and Soldering applicator in our in house facility and other industrial facility , we train from scratch and make the experts in them.

This blog answers the below basic questions :

- What is Brazing ?

- Where is brazing used ?

- What is the flux used in brazing for ?

- What is the filler metal used for brazing ?

- What is the step by step process of brazing ?

- Where to get training for brazing and qualification certificate for brazing ?

- What is peel Test ?

Brazing is the process of joining materials using filler metals like brass ( copper & Zinc alloy) with has less melting point than the base metal .

Mostly brazing is used for Joining dissimilar materials and the joint will be interference fit as shown below .

Applications of Brazing :

- Tubes of Heat Exchanger systems,

- Refrigeration pipelines

- Air purifying systems ,

- Radiators,

- Tooling & Jewellery

Filler metals for Brazing:

Filler metals used for brazing are metals with lower melting point than the base metal, the filer metal will have low surface tension as liqud when heated .

The filler metal travel into the small gaps of the joint due to capillary action, i.e: the filler metal when in liquid state it gets absorbed by the dry inner surface of the base metal due to surface tension.

So it is essential to keep the surface of the joint to be dry and clean, this is achieved by pre-cleaning, flux application and preheating.

Below are the step by step instruction for Brazing Process :

- Cleaning is done by appropriate means in the joining area to remove the oxides / oil / greese/ paint/ any other contaminants

- Joint Preparation : Butt/Scarf/Lap/any joint is possible in soldering, I prefer a lap joint with interference fit ( Example: Socket joint) to facilitate a large area of joining and make a leak proof joint .

- Use a brazing torch and light the flame using gasses Acetylene and Oxygen .

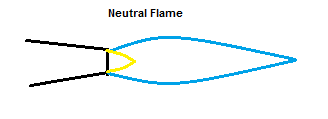

- Achieve a Neutral flame by making the oxygen and Acetylene flow 1:1

- Apply the Flux in the mouth of the joining area, also dip the filler edge into the flux

- Pre-Heat the joining area and then hold the flame in the areas where filler metal is needed to be applied , typically the neutral flame is 1250°C and the metal in front of the flame to be heated more than 460°C

- At a temperature more than 460°C the Filler metal (example: Brass) melts and sticks to the base metal.

- Make sure the heat is continuously applied for more time, to make sure the filer metal remains in a liquid form until it reaches the end of the joint using a capillary action.

- Make sure to dip the filler metal in flux then and then.

Why is Flux used in brazing?

The purpose of flux is to prevent oxidization and facilitate good flow of filler in to the joint .

However the flux is not required for copper to copper brazing . and still flux application is good for making the filler metal flow better .

Peel Test :

Peel test is a suitable destructive test to check the penetration of filler metal into the joint .

An alternate for peel test is Macro analysis in the sectioned area.

Guidelines of peel test and peel test equipment is given in standard ASME BPVC section IX.

For more training or certifications for brazing operator , please feel free to contact us through [email protected], [email protected], https://aqcinspection.com .

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or