Arc welding on SS material :

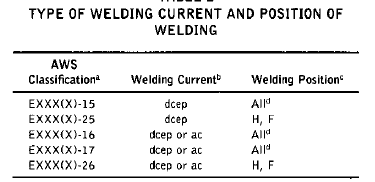

- Electrode specification standard : AWS A 5.4

- Gas – Not required

- Example of electrode spec:

Austenitic SS : E209, E316, E308, E309, E316, E316L (L – Low Carbon),

Martensitic : E410-16

Precipitation hardened : E7Cr-16

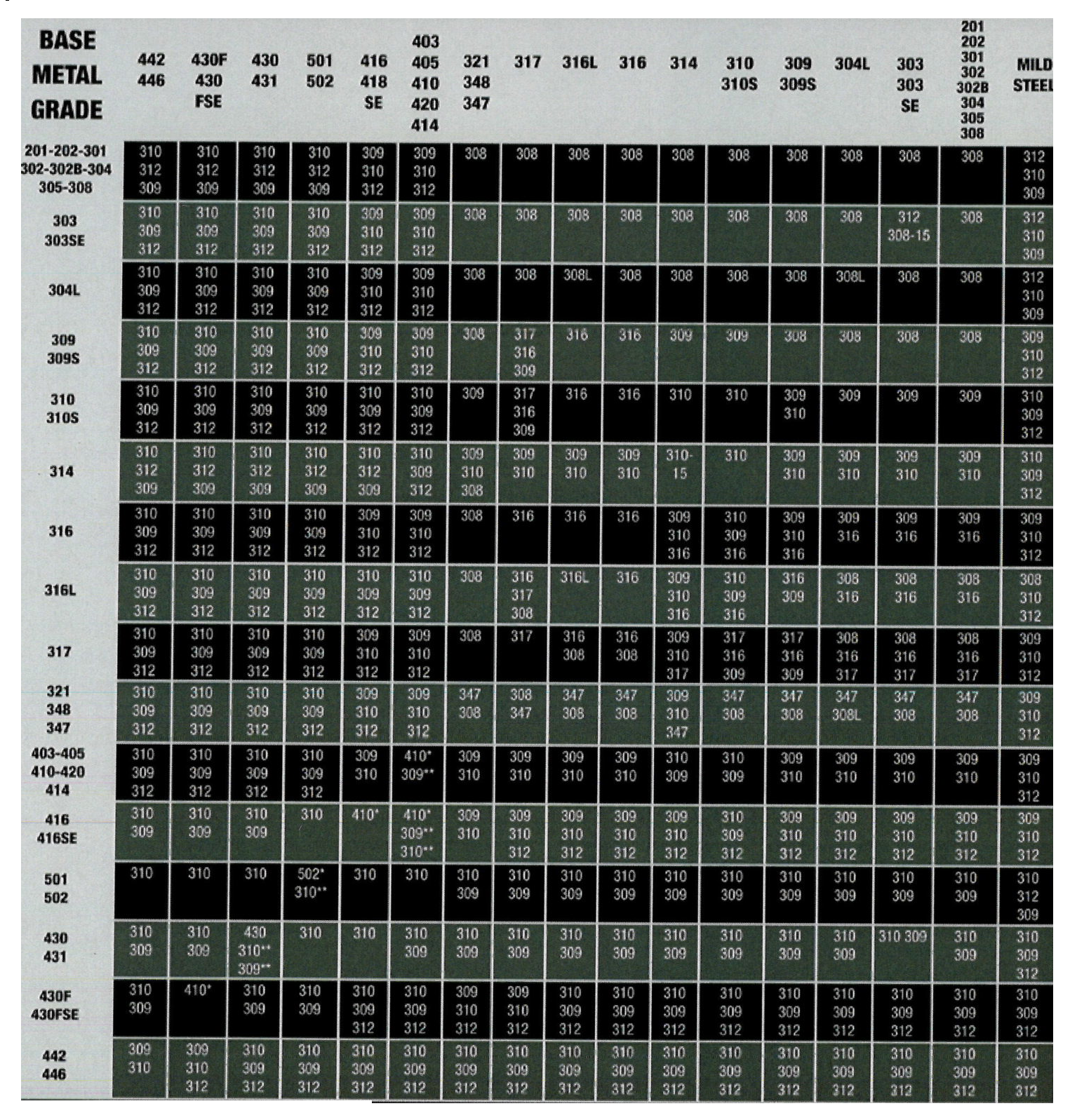

Enclosed herewith the Electrode selection chart for the Stainless steel grades

- Flux Coating: Lime coated , Titanium coated

Welding Procedure

- Weld with low heat input,

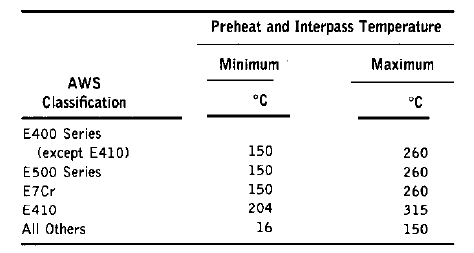

- No pre heat required for Austenitic SS

- Maximum interpass temperature shall be 150 degree celcius

- Good to allow to cool to almost ambient temperature before welding consecutive runs .

- Remove the oxide layers with appropriate methods such

- Pre Heat is not required for Austenitic Stainless Steels (min: 16°C)

Proper cleaning of slag and is essential in SMAW – Arc welding on SS material. The cleaning is done using SS grade Materials ( example: Cutting wheel, Chisel, Hammers, SS wire brush and separate tools for SS) . Make sure the Material is not contaminated by carbon steel.

After welding , pickling passivization shall be carried out to remove the tint oxide layer over the material.

For more training or certifications for welding operator , please feel free to contact us through [email protected], [email protected],

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or