Brazing is a process of joining dis-similar metal, where as welding is a process of joining similar metal. In this blog we can see about some of the details in Brazing procedure qualification

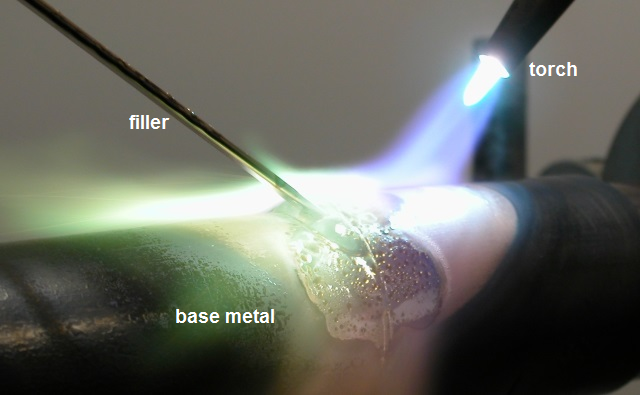

Brazing involves melting of filler metal and flowing over the joining surfaces. The filler metal used is generally of lower melting point than the base metal. the base metal is just pre heated to make it readily fusible.

The filler metals flows in to the gaps of closed fitted base metals by capillary action.

The different types of brazing are :

- Torch Brazing

- Furnace Brazing

- Induction Brazing

- Resistance Brazing

- Dip Brazing

The Brazing Process required a qualified Brazing Procedure (similar to a WPS , Welding Procedure Specification) and a Brazing operator qualification (similar to a welder qualification certificate ) .

The gas used for producing the gas flame is generally Acetylene with Oxygen.

Brazing Procedure & Approval

The standard ASME BPVC , Section IX has qualification variables and ranges for brazer qualification and brazing procedure qualification.

- ASME BPVC section IX, Article XII gives us the guidelines for Brazing Procedure Qualifications and

- Article XIII for Brazing Performance Qualifications,

- Non mandatory appendix B – sample format for procedure preparation

- QB-482 – Suggested Format for Brazing Procedure Specification

- QB-483 – Suggested format for Brazing Procedure Qualification Record

- QB-484 – Suggested format for Brazing Operator Performance Qualification

The Base metals for brazing have P number as shown below & P.No’s can be selected from TableQW/QB-422 :

- Steel & Steel Alloys – P.No.101 through P.No.103

- Aluminium & Al Alloys – P.No.104 through P.No.105

- Copper & Copper Alloys- P.No.107 through P.No.108

- Nickel & Nickel Alloys – P.No.110 through P.No.112

- Titanium & Titanium Alloys – P.No.115

- Zirconium & Zirconium Alloys – P.No.117

Essential Parameters for Brazing:

- Base Metal

- Filler Metal

- Flux, Gas

- Flow Position

- Joint Design

- Post Braze Heat Treatment

- Technique

Procedure Qualification Procedure:

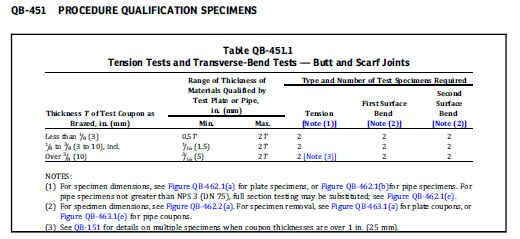

- A sample test coupon is prepared of dimension sufficient for performing all the tests, the range of thickness qualified is given in QB-451 .

- Qualification of Pipe also qualifies plate.

- Perform the required tests on the brazed specimen, ex: 2 Tensile & 4 Bend tests as given in the table.

- Or For Lab Joints, perform 2 Tensile and 2 Peel off test

- Similarly all brazers are made to braze a sample test coupon and tests are made as per table QB-452

- Note that peel test may be substituted by sectioning tests, where it is impractical to perform.

For Trainings on brazing, brazing procedure qualification and brazer or brazing operator approval, please feel to contact https://aqcinspection.com/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or