Helium leak testing is a critical procedure used to identify and measure the presence of helium leaks in various systems, often employed in aerospace, industrial, and manufacturing applications due to helium’s small atomic size and inert properties.

Key Concepts in Helium Leak Testing:

- Helium as a Tracer Gas: Helium is ideal for leak detection because it is inert, non-toxic, and has a small atomic size, allowing it to escape through very small leaks that other gases cannot.

-

Testing Methods:

- Vacuum Testing: Involves placing the object in a vacuum chamber and spraying helium on its surface. Any helium that enters the chamber indicates a leak.

- Sniffer Testing: Helium is introduced inside the object, and a “sniffer” probe is used to detect helium escaping from any leaks on the outside.

- Pressure Decay Method: This method measures the loss of pressure in a system over time, with helium used to fill the system initially.

-

Applications:

- Aerospace: Testing the integrity of fuel systems, thrusters, and other critical components.

- Manufacturing: Ensuring the leak-tightness of components like heat exchangers, valves, and pipelines.

- Medical Devices: Verifying the seal integrity of devices that need to be sterile and leak-free.

Recent Developments:

- Boeing Starliner Helium Leak Issues: The Boeing Starliner spacecraft encountered multiple helium leaks in its propulsion system during recent missions to the ISS. These leaks affected the spacecraft’s performance but were mitigated by thorough testing and adjustments. Engineers used thruster tests to understand the behavior of helium leaks under operational conditions, noting that leak rates decreased over time due to thermal activity from the thrusters or seal wear (SpaceNews) (SciTechDaily) (Space.com).

- Advanced Leak Detection Technologies: New technologies are enhancing the sensitivity and accuracy of helium leak detection. Innovations include more sensitive mass spectrometers and automated detection systems that provide real-time monitoring and analysis, reducing human error and increasing efficiency.

- Helium Supply Challenges: The global supply of helium is limited, which has driven the development of more efficient testing methods that use less helium. Companies are also exploring alternative tracer gases and improving recycling methods for helium used in leak detection.

Practical Implementation:

-

Preparation:

- Ensure the test environment is free of background helium.

- Calibrate detection equipment before testing.

-

Testing:

- Apply the chosen method (vacuum, sniffer, or pressure decay).

- Record and analyze the data to determine the presence and size of any leaks.

-

Post-Testing:

- Implement corrective actions for detected leaks.

- Perform re-testing to confirm the integrity of the system after repairs

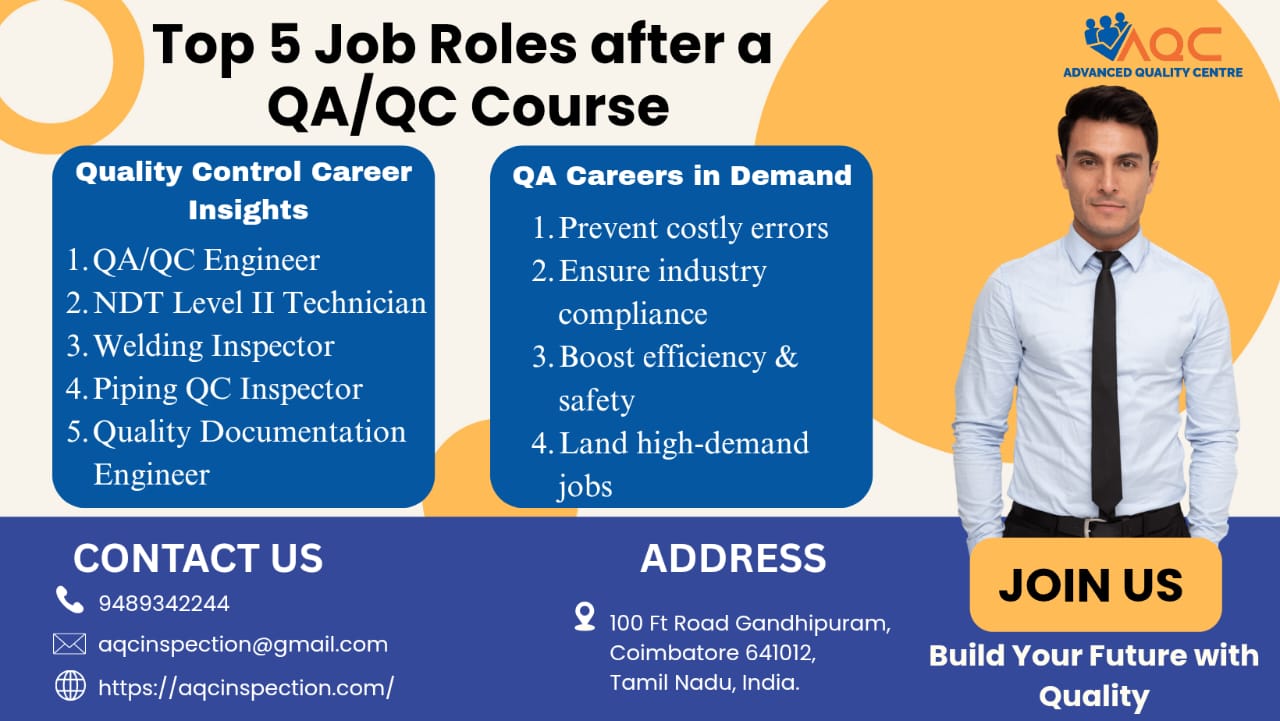

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in best NDT training institute.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or