blogs, Job Assistance, Training

blogs, Job Assistance, Training

blogs

Navigating the Future of NDT Courses : Trends and Innovations

Introduction: In the ever-evolving landscape of Non-Destructive Testing (NDT), staying current with the latest trends and innovations is crucial for professionals and students alike. NDT courses plays a pivotal role in ensuring the safety and integrity of structures, components, and materials across various industries. As…blogs

Exploring the Brilliance of Laser Welding

Introduction In the realm of modern manufacturing and engineering, laser welding has emerged as a revolutionary technique, offering unparalleled precision and efficiency. By employing focused laser beams, this advanced process joins materials with exceptional accuracy, minimal heat-affected zones, and reduced distortion. In this comprehensive guide,…blogs

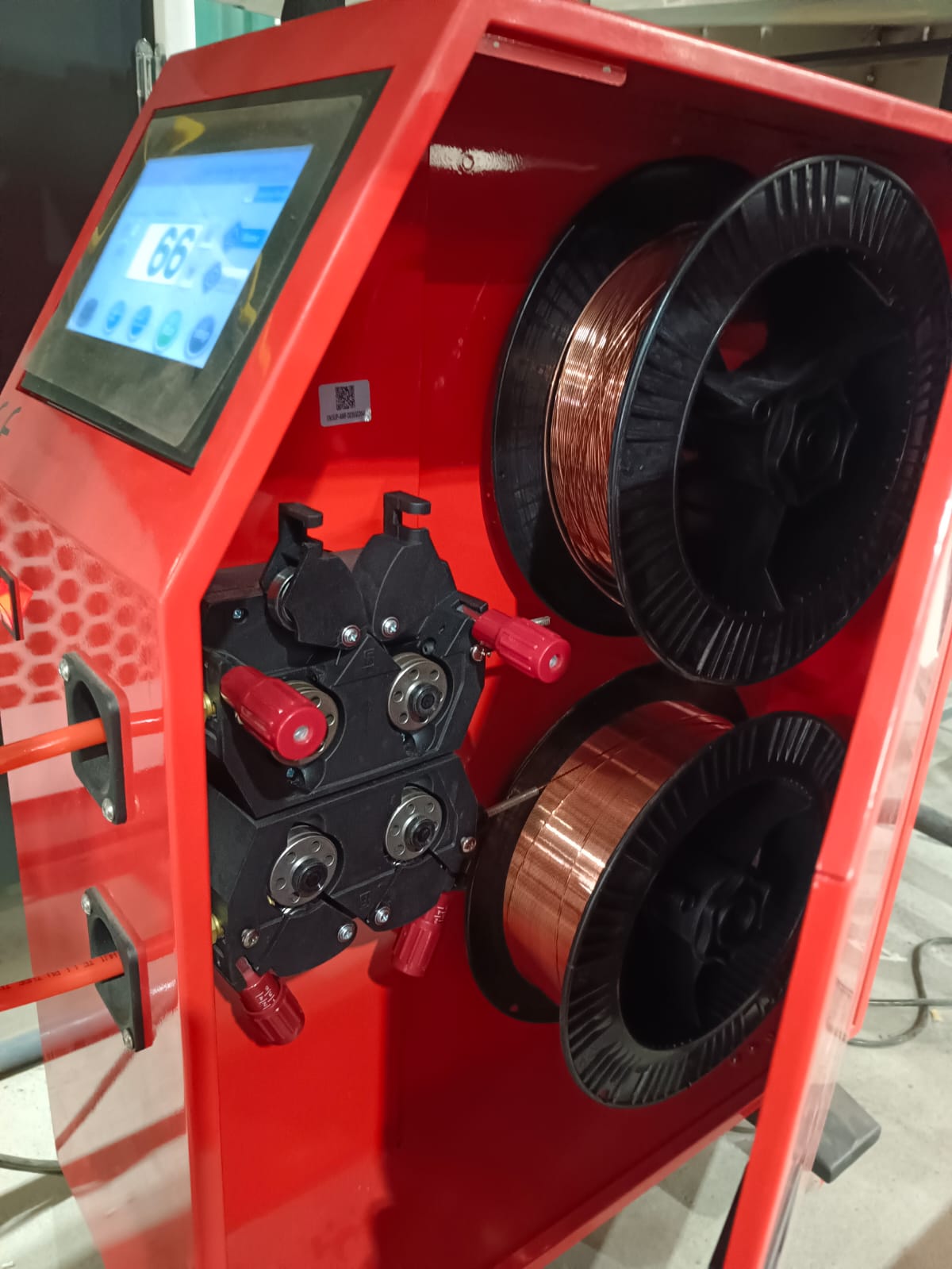

Difference between Filler Metal and Electrode

What is Welding? Process of joining similar metals, (or thermoplastic) By heating them to suitable temperature May or may not require pressure. May or may not require Filler metal What is Brazing ? Process of joining dis-similar metals, by melting and pouring the filler…blogs

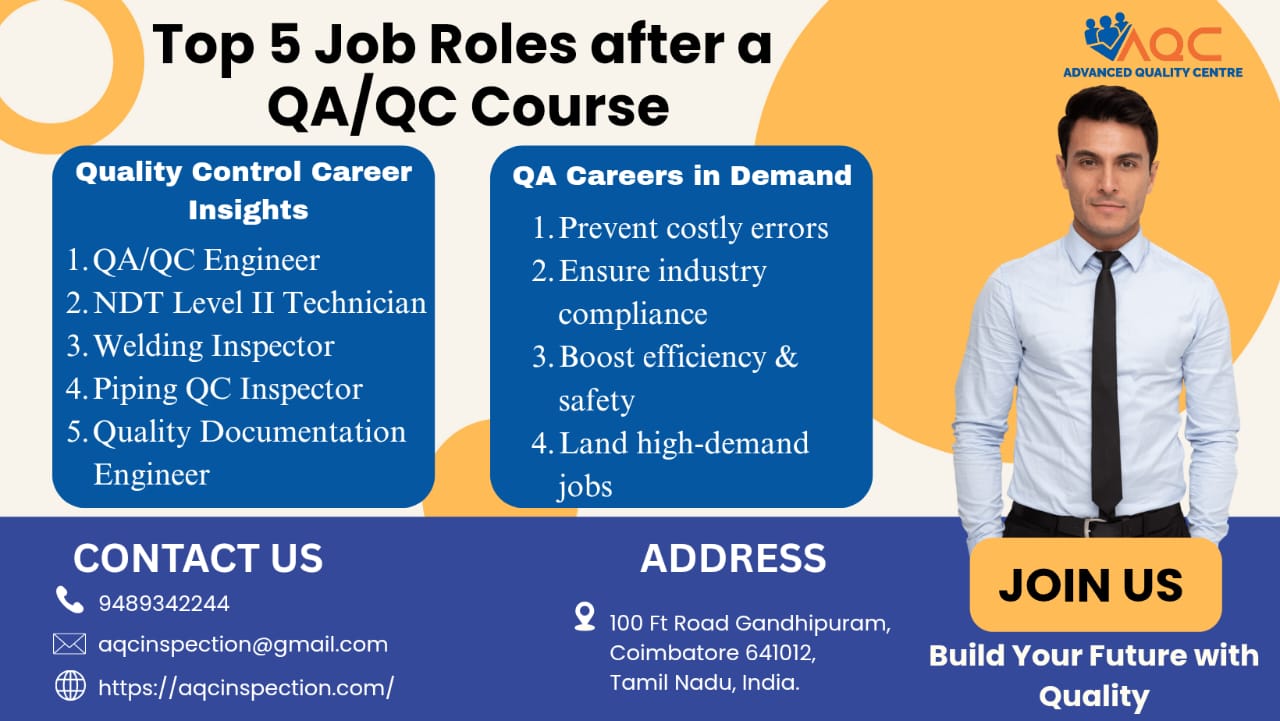

QC course for Mechanical Engineers

Part time QC course for Mechanical Engineers Quality Control and Quality Assurance Department is a satisfying career field, and is one among the core job. Quality Assurance and Quality Control nowadays had become essential in all industries, particularly in manufacturing and construction industries. It may include…blogs

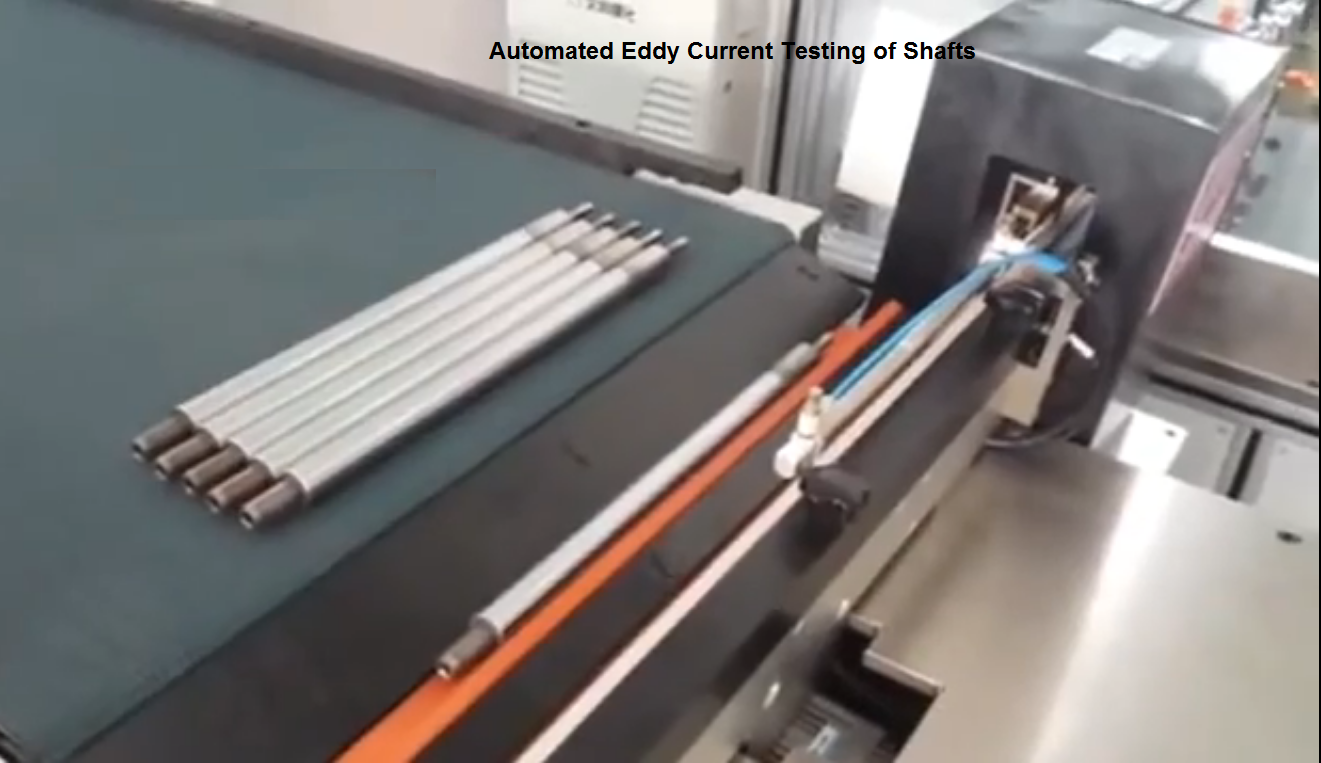

NDT on Shafts

Non Destructive Testing,NDT on Shafts is considered essential , because the shafts are mostly made as load bearing structures, any defects such as cracks will propagate more during acting of load and eventually will cause failure. The most possible defects in shafts are Cracks and…blogs

Oil and gas jobs

Below are the list of Oil Gas Companies which might guide the Job seekers to apply and get oil and Gas Jobs opportunities / foreign jobs . People with various qualifications as Engineers of Process Engineering, Designing, Non Destructive Testing NDT, Welding Inspection, Instrumentation, HVAC,…blogs

Steel Making Process

Steel Making Process Steel is an alloy of iron usually containing less than 1.5% carbon. Steel can be cast into bars, strips, sheets, nails, spikes, wire, rods or pipes as needed by the intended user. Steel making process at an integrated steel plant involves three basic…blogs

Material Testing

Material testing Mechanical testing have been designed to test several weld properties.Few other material testing techniques are Charpy V-Notch Toughness: Notch toughness is the capacity that a material possesses to absorb energy in the presence of a flaw, such as a notch or crack. The material will…Training