blogs

blogs

blogs

Hardness Test- types

Rockwell Superficial Hardness Test: The Rockwell Superficial Hardness Tester is used to test thin materials, lightly carburized steel surfaces, or parts that might bend or crush under the conditions of the regular test. This tester uses the same indenters as the standard Rockwell tester but…blogs

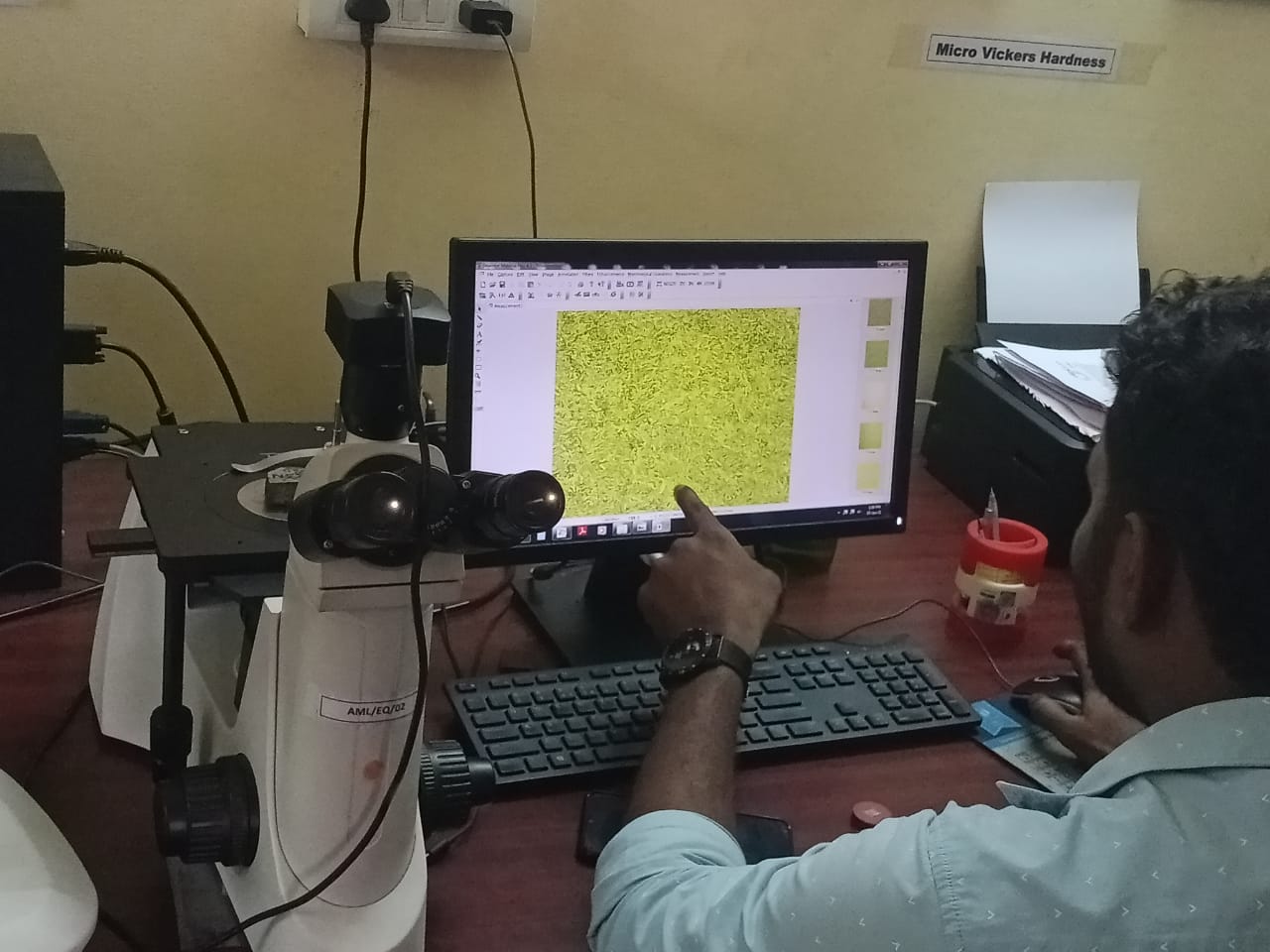

Hardness Testing

Hardness Testing: Hardness is the resistance of a material to localized deformation. The term can apply to deformation from indentation, scratching, cutting or bending. In metals, ceramics and most polymers, the deformation considered is plastic deformation of the surface. For elastomers and some polymers, hardness is…blogs

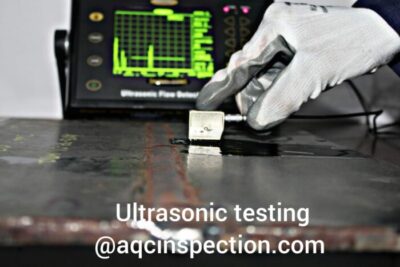

Non destructive Testing (NDT)- Common Methods

Non destructive Testing (NDT)- Common Methods are: Visual Inspection – VT Liquid Penetrant Testing – LT Magnetic Particle Testing – MT Radiographic Testing – RT Ultrasonic Testing – UT 1. Visual Inspection – VT: Visual inspection after welding is very useful in evaluating quality, even if…blogs, Training

Cast Iron and Its Types

What is a cast iron? Cast iron are ferrous alloys with greater than 2% carbon. They also contain small amounts of other materials such as silicon, sulphur, manganese, & phosphorous. In general it consists alloys of carbon & iron. They are the least expensive of all metals and…blogs

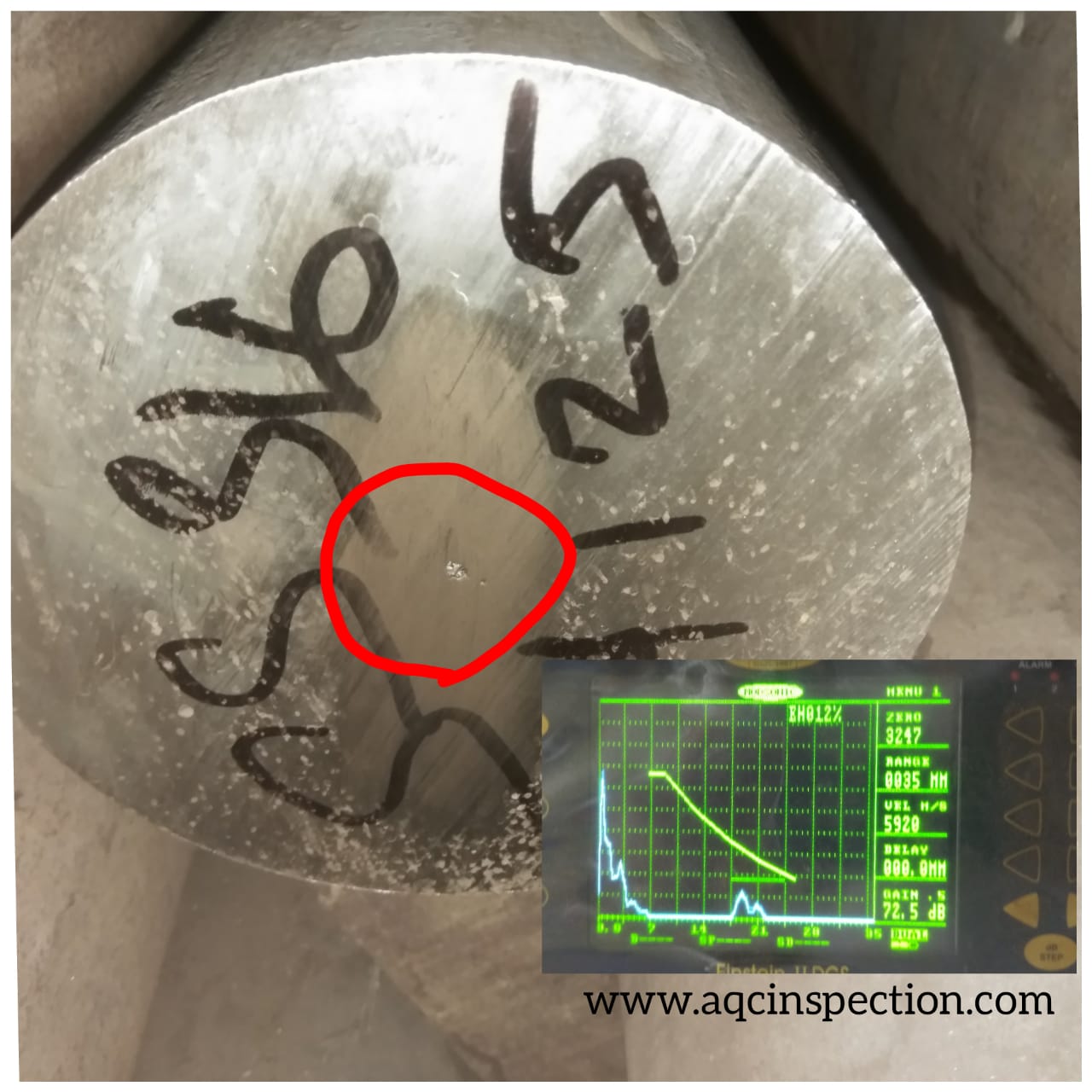

Acceptance Criteria for Ultrasonic Testing

How to interpret Acceptance Criteria for Ultrasonic Testing as per AWS D1.1 The Requirements of Ultrasonic Flaw detector equipment as per AWS D1.1 Structural Steel Welding code is given below: Equipment: The ultrasonic equipment’s shall be pulse echo type ‘A’ scan suitable for use with transducers…blogs

Non Relevant Ultrasonic Indications

Non relevant Ultrasonic Indications can usually be identified as one of the following: Electrical Interference Interference form the transducer (search unit) Interference form the surface of the specimen Interference caused by mode conversion of the sound beam Interference caused by the shape of the…blogs

ISO Standards for Ultrasonic Testing

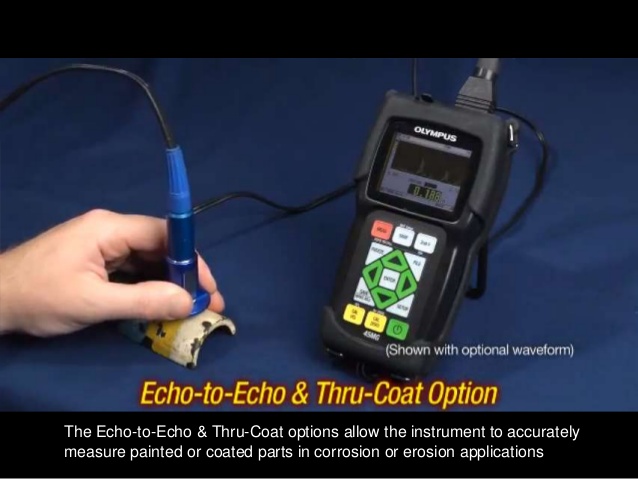

Ultrasonic Testing In Ultrasonic Testing we use something called “Ultrasonic Vibrations” we must know two facts about a vibration: A vibration is a back and forth movement. A vibration is energy in motion A depression of a surface from its normal position is called a displacement.blogs

Ultrasonic testing Couplants

A study on the couplant effects in contact ultrasonic testing. The primary purpose of a couplant is to provide a suitable sound path between the transducer and the test surface.Ultrasonic Testing couplants usage can be seen here A couplant must effectively wet or totally…blogs