blogs

blogs

blogs

Welding Inspector certification

Levels of Certification AWS 1:2003 There are three levels of qualifications for welding inspector personnel. These levels are: AWI – Associate Welding Inspector; WI – Welding Inspector; SWI – Senior Welding Inspector. 1.1) Associate Welding…blogs

WELDING EQUIPMENT

Most field welding machines are portable, that is, they are on a truck and can be moved around. The welding equipment is usually a generator driven by a gasoline-powered engine and puts a DC current that may be reversed by changing the leads. The welding…blogs

Welding Procedure for Overlay Weld or Cladding

This document covers the procedure to prepare a WPS – Welding Procedure Specification & PQR – Procedure Qualification Record for Overlay weld, Corrosion Resistant Overlay and Wear Resistant Overlay both. The procedure refers international standard ASME BPVC Section IX, ( American Society of Mechanical Engineers,…blogs

CLASSIFICATION OF WELDING ELECTRODES

Classification of welding electrodes consists of a prefix letter “E” specifying an electrode, a group of two or three digits specifying weld metal strength in ksi in the ‘as-weld’ or stress relieved condition, and a final two digits specifying type of covering, weld position…blogs

WELDING PROCESSES

The welding processes are not the scope of this manual, specific for welding inspections. However, only for refreshing, the most common arc welding processes used in heavy and medium carbon and alloy steel manufacturing are: SMAW: Shielded Metal Arc Welding – stick welding electrode; GMAW: Gas…blogs

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2

Fillet Weld Sizes as per AWS D1.1 & AWS D1.2 This blog here answers your questions about: What is the tolerance for Fillet weld sizes as per AWS D1.1 ? What is the weld size tolerance? What is the required fillet weld size for structures…blogs

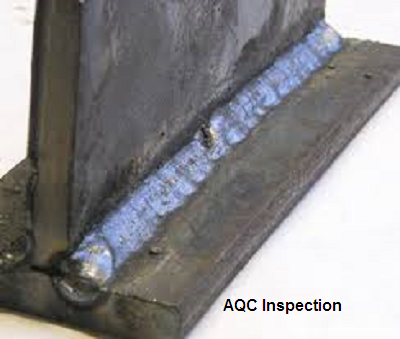

Fillet Weld Types

Fillet Weld Types: The single-fillet-welded T-joints are indicated from both the arrow side and the other side. The symbol for a double fillet-welded T-joint is also Note that the assembly of two T-joints welded pieces involves four fillet welds represented by two double-fillet-weld symbols.blogs

Standards and Specifications for welding

WELDING INSPECTOR KNOWLEDGES: The Welding Inspector must be a high skilled technician or engineer with a good knowledge of general industry manufacture, materials, quality systems, inspection procedures and Standards and Specifications for welding as: Standard organizations as ASTM, SAE, AISI, AWS, ASME and other institutions; …blogs