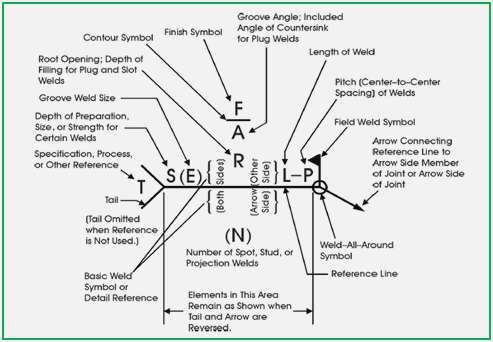

Elements of Welding Symbols:

The first concepts the Welding Inspector must understand very well, are the welding symbols and how to interpret them on drawings. The reference line of the welding symbol, as shown below, is used to designate the type of weld to be made, its location, dimensions, extent, contour, and other supplementary information.

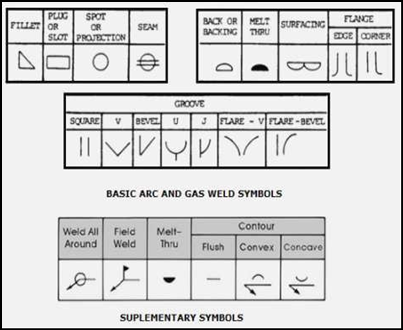

Supplementary Symbols:

A distinction is made between the terms “weld symbol” and “welding symbol”. The “weld symbol” below indicates the desired type of weld. The “welding symbol” consists of the following eight elements, or any of these elements are necessary:

Supplementary information: Reference line, arrow, basic weld symbols, dimensions and other data, supplementary symbols, finish symbols, tail, and specification, process, or other reference.

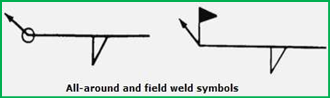

The circle used as the weld-all-around symbol means that welding is to be all around the joint. The small flag, or field weld symbol, means the weld is to be made in the field. The solid black semicircle, or melt-thru symbol, indicates the weld is made by melting through the top piece into a lower piece.

The tail of the symbol is used for designating the welding and cutting processes as well as the welding specifications, procedures, or the supplementary information in making the weld.

If a welder knows the size and type of weld, he has only part of the information necessary for making the weld. The process, identification of filler metal that is to be used, whether or not peering or root chipping is required, and other pertinent data must be related to the welder.

Definitions of Weld Symbols:

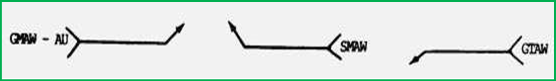

- When the use of a definite process is required the process may be indicated by one or more of the letter designations, as

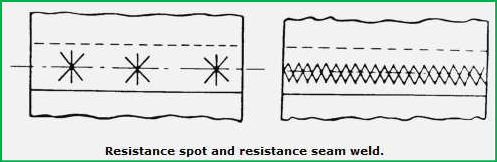

Obs.: Letter designations have not been assigned to arc spot, resistance spot, arc seam, resistance seam, and projection welding since the weld symbols used are adequate.

2. When no specification, process, or other symbol, the tail may be The reference is used as an indication of a common welding process.

3.Other common weld symbols, as above and below, illustrate the weld-all-around and field weld symbol, and resistance spot and resistance seam

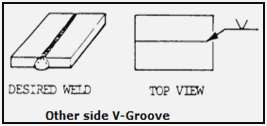

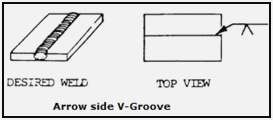

Location Significance of Arrow:

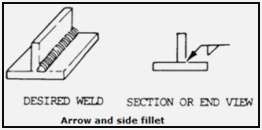

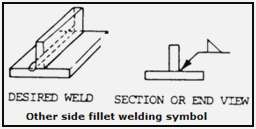

- Fillet, Groove, Flange, Flash, and Upset welding symbols. For these symbols, the arrow connects the welding symbol reference line to one side of the joint and this side shall be considered the arrow side of the joint. The side opposite the arrow side is considered the other side of the joint.

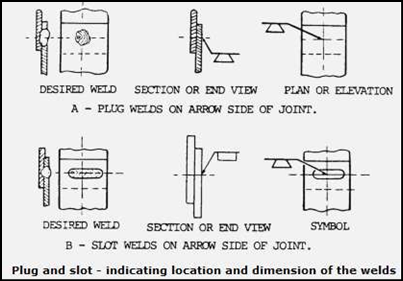

2. Plug, Slot, Arc Spot, Arc Seam, Resistance Spot, Resistance Seam and Projection For these symbols, the arrow connects the welding symbol reference line to the outer surface of one part of the joint at the center line of the desired weld. The part to which the arrow points is considered the arrow side. The other part of the joint shall be considered the other side.

3. Near Side. When a joint is depicted by a single line on the drawing and the arrow of a welding symbol is directed to this line, the arrow side of the joint is considered as the near side of the joint, in accordance with the usual conventions of drafting.

we provide standard specifications for welding procedures for all welding process and Brazing. We offer Welder Procedure Specification, Welder Certificate Renewal Process, Procedure Qualification Record, Welder Qualification Testing, welder Training and Welder qualification services in Coimbatore, Trichy, Salem, Erode, Chennai.

Please feel free to reach us https://aqcinspection.com/training/ to learn more about any of the methods in detail.

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

https://ndtcenter.blogspot.com