TASKS DURING WELDING OPERATIONS

Welding inspection during welding operations should

include all the audit parameters to verify that the welding is performed to the procedures. Such tasks may include the following:

Quality Assurance

Establish a quality assurance and quality control team

with the welding organization.

Quality control items to assess:

- Welder is responsible for quality craftsmanship of

weldments. - Welder meets qualification requirements

- Welder understands welding procedure and requirements

for the work. - Special training and mock-up weldments performed if

required. - Welder understands the inspection hold-points.

Potential inspector actions:

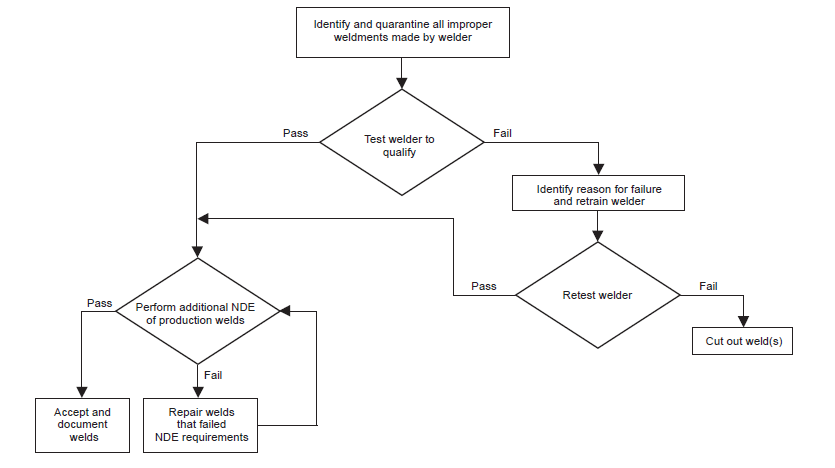

Review welder performance with welding organization as below

Welding Parameters and Techniques

Confirm welding parameters and techniques are supported

by the WPS and WPQ.

Quality control items to assess:

1.Essential variables are being met during welding.

- Filler material, fluxes, and inert gas composition/flow

rate. - Purge technique, flow rate, O2 analysis, etc.

- Rod warmers energized or where rod warmers are not

employed, the welder complies with maximum exposure

times out of the electrode oven. - Preheating during tack welding and tack welds

removed (if required). - Welding technique, weld progression, bead overlap,

etc. - Equipment settings such as amps, volts, and wire

feed. - Preheat and interpass temperatures.

- Travel speed (key element in heat input).

- Heat input (where appropriate).

2. Mock-up weldment, if required, meets requirements with welder and welding engineer.

3. Welder displays confidence and adheres to good welding practices.

Potential inspector actions:

- Review mock-up weldment problems with welding

engineer. - Review welder quality with welding organization.

Weldment Examination

Complete physical checks, visual examination, and in-process

NDE

Quality control items to assess:

- Tack welds to be incorporated in the weld are of acceptable

quality. - Weld root has adequate penetration and quality.

- Cleaning between weld passes and of any back-gouged

surfaces is acceptable. - Additional NDE performed between weld passes and on

back-gouged surfaces shows acceptable results. - In-process rework and defect removal is accomplished.

- In-process ferrite measurement, if required, is performed

and recorded. - Final weld reinforcement and fillet weld size meets work

specifications and drawings.

These are the tasks welding inspector course fees. Trainings for welders, trainings for Welding inspections, Courses and Certification for performing NDT, consultancies for welding procedure Specification WPS , Welder qualification in Coimbatore etc., are readily available globally everywhere, for more assistance contact experts at https://aqcinspection.com/ .

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . https://ndtcenter.blogspot.com our website https://aqcinspection.com/news-events/ for many more blogs