- Visual Inspection

- Inspection Stages: Inspections should be performed at different stages of the welding process, including tacking, root pass, filler pass, and cap pass, with particular attention paid to the root and cap areas.

Responsibilities of the Inspector:

- Observe, identify, and possibly measure the features of the weld.

- Assess whether the weld meets the required quality standards, based on either company-specific criteria or national codes.

- If the defect exceeds allowable limits, either request approval for a concession from a qualified person or reject the weld.

- Visual Inspection Tools

- Lighting: Proper lighting is essential to conduct a thorough inspection.

- Magnification: The magnification should be between 2x and 2.5x; for higher magnification, a binocular microscope is recommended.

- Inspection Equipment: Tools such as hand torches, mirrors, magnifiers, and light sources may be used to improve visibility.

- Remote Probe Units: These should have:

- A wide field of view.

- No distortion of images.

- Accurate color reproduction.

- Sufficient lighting for proper visibility.

- Code of Practice for Inspection

- General Guidelines:

- Inspectors should be familiar with all relevant documents, standards, and good workshop practices.

- They should understand how to use tools and measuring devices effectively.

- While full implementation of the code may be costly, inspectors should follow a reasonable approach to meet inspection requirements.

- Pre-Welding Inspection

- Before Assembly:

- Verify all relevant documents, including the quality plan, welding procedure sheets, welder qualifications, and the latest approved revisions of drawings and standards.

- Ensure material certificates, cutting and machining methods, and safety permits (e.g., hot work permits) are in place.

- After Assembly:

- Check that dimensions, fit-up, alignment, and cleanliness meet the approved drawings and standards.

- Ensure proper preheating and tack welding procedures are followed.

- Inspection During Welding

- Monitoring the Process:

- Monitor key aspects of the welding process, such as preheat and interpass temperatures, welding sequence, and welding parameters (current, voltage, travel speed).

- Ensure the correct selection of filler metals, fluxes, and shielding gases, and verify compliance with welding procedures.

- Post-Welding Inspection

- Key Checks:

- Perform visual inspections to assess the weld appearance.

- Verify dimensional accuracy and compliance with the drawings.

- Confirm that post-weld heat treatment (if required) has been performed and that non-destructive testing (NDT) is conducted.

- Evaluate any defects to determine whether repairs are needed or if a concession should be requested, and ensure distortion is managed.

- Repair Procedures

- Repair Process:

- Ensure that the repair procedure and welding code are authorized.

- Clearly mark the defect areas and verify that removal and re-welding are done properly.

- Re-inspect the repaired areas and compile the necessary documents for final approval.

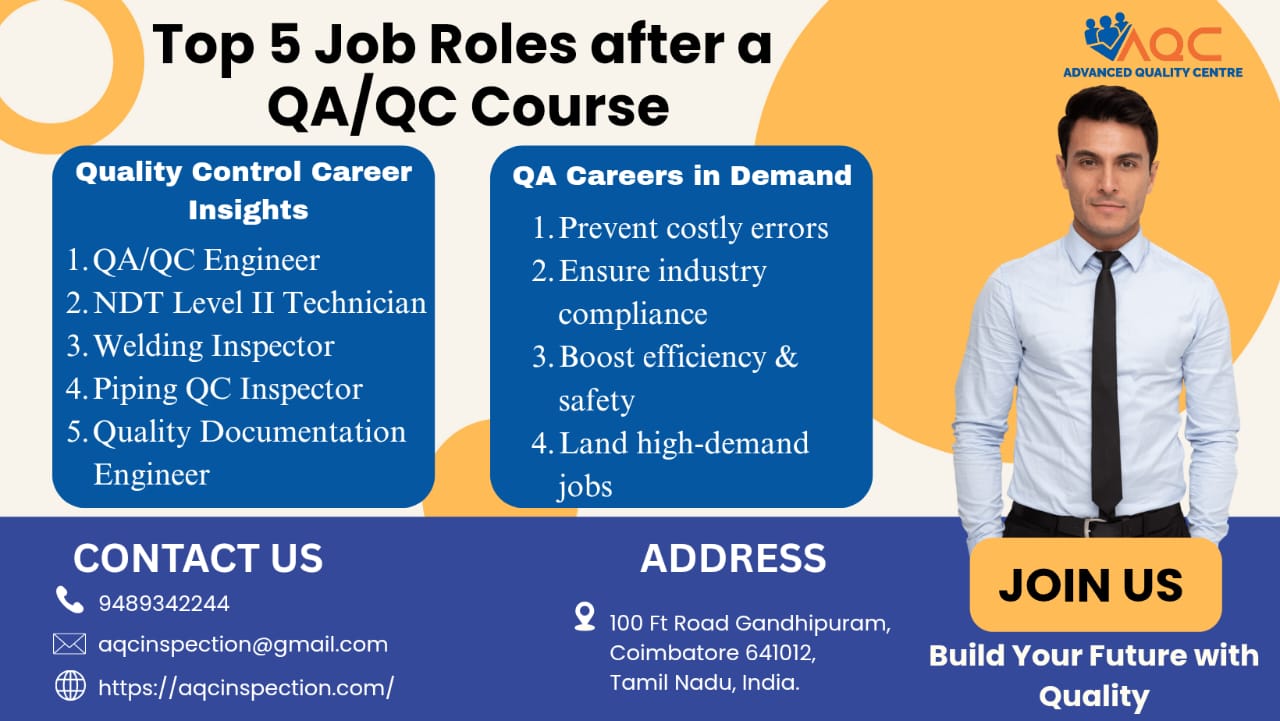

- Welding Inspector Responsibilities and Qualities

- Responsibilities: The inspector ensures compliance with standards, monitors workmanship, and enforces welding criteria by overseeing work and documentation.

- Key Attributes: Inspectors should be honest, have integrity, be literate, physically fit, and possess good eyesight.

- Duties of the Welding Inspector

- The primary duties of a welding inspector involve observing, measuring, and identifying issues during the welding process to ensure that the work complies with the relevant standards and specifications.

For more training or certifications for welding operator , please feel free to contact us through [email protected], [email protected], https://aqcinspection.com .

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or