NDT training for Visual Testing

Visual Testing is considered most important of all non destructive testing method, as it is most essential and first step in a inspection process.

Visual Testing requirement

The first thing to make sure for a visual testing is the visual acuity of the visual inspector. As a minimum the inspector should have a clear near vision and no colour blindness. These eye tests should be carried pit at least early once to verify the eye sight of the inspector.

The next major thing for visual inspection is Lighting, use both fixed lamps and hand torches for inspection. Most standards requires a minimum light intensity of 1076LUX at the area of inspection. It is allways better to have light or eye sight very perpendicular to the surface of inspection area.

Visual inspection training courses

Visual inspection NDT training courses consists of below contents :

* Inspection aids (torch, mirrors, magnifying glass, etc)

* inspection instruments ( vernier, height gauge, measuring tapes , rules, dumpy levels, trimos , weld gauges , etc )

* training to read fabrication drawings, machine drawings, piping isometric drawings, P&ID drawings, GD&T, Symbols for weld, surface finish , etc )

* factors such as temperature, atmosphere, size, texture, etc ,

* documents such as QAP, ITP, MTC, MAR , Visual reports , dimensional reports, etc ,

* casting defects such as air voids, incursions, shrinkage, cracks, hot tear, cold shit, segregation, lamination , laps, piping, seams, mis-match, mis-run, etc.

* welding defects such as undercut, under fill , lack of fusion, lack of penetration, slag inclusion, porosity , excess penetration, excess weld bead , burn trough , craters , star cracks , HAZ cracks, suck back, overlap, spatters , arc strike, mis-alignment, distortion, etc.

* Acceptance standard for visual inspect such as AWS D1.1 table 8.1, ASME section IX, ASME B16.34, ASME B31.3, ASME section VIII, and ISO or SAE AMS standards .

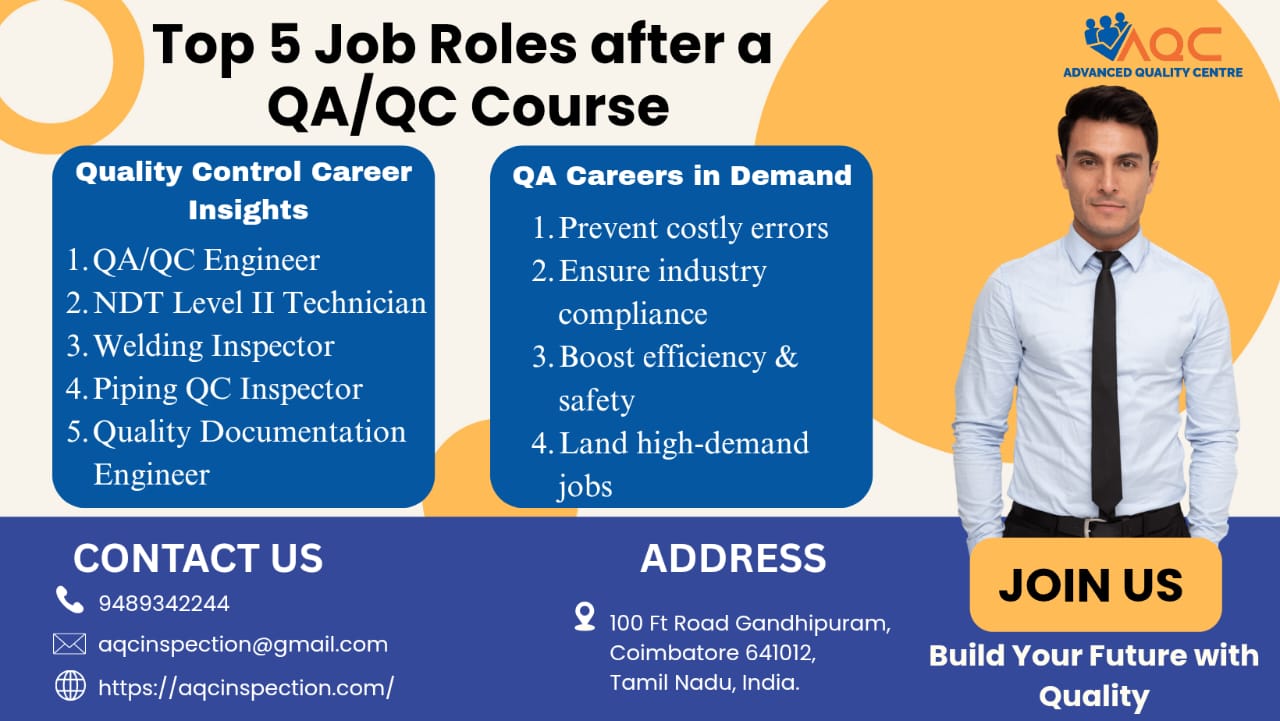

For training and certifications of visual inspection methods , procurement of visual defect samples, please get in touch with s on mobile :09489342244, phone: 04224342244, email: [email protected], website: https://aqcinspection.com/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

https://ndtcenter.blogspot.com

Subscribe our youtube channel to know more practical explanations https://aqcinspection.com/