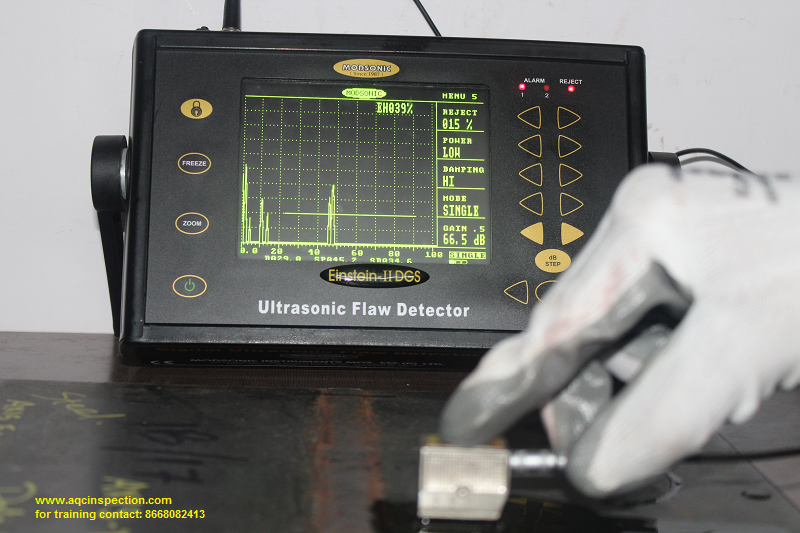

Ultrasonic testing involves sound waves , that is otherwise called as vibration traveling inside a medium , the ultrasonic sound waves gets reflected back whenever there is change in a material ( different acoustic impedance ) , the reflection is more when the sound meets Air voids as the impedence difference is huge .

Probe Selection

Probe Frequency:

Conventional UT , has probe with frequencies form 1 MHz to 10 MHZ

Higher the frequency more sensitive the inspection are , but also consider that very high frequency probes will produce more scatter noises from the grain boundaries of the metal. Probe of 4 MHz is common , chose a lower probe of 2 MHz only when the material is with poor or coarse grain structure.

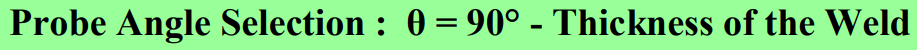

Probe Angle Selection :

As a thumb rule, consider the below formula

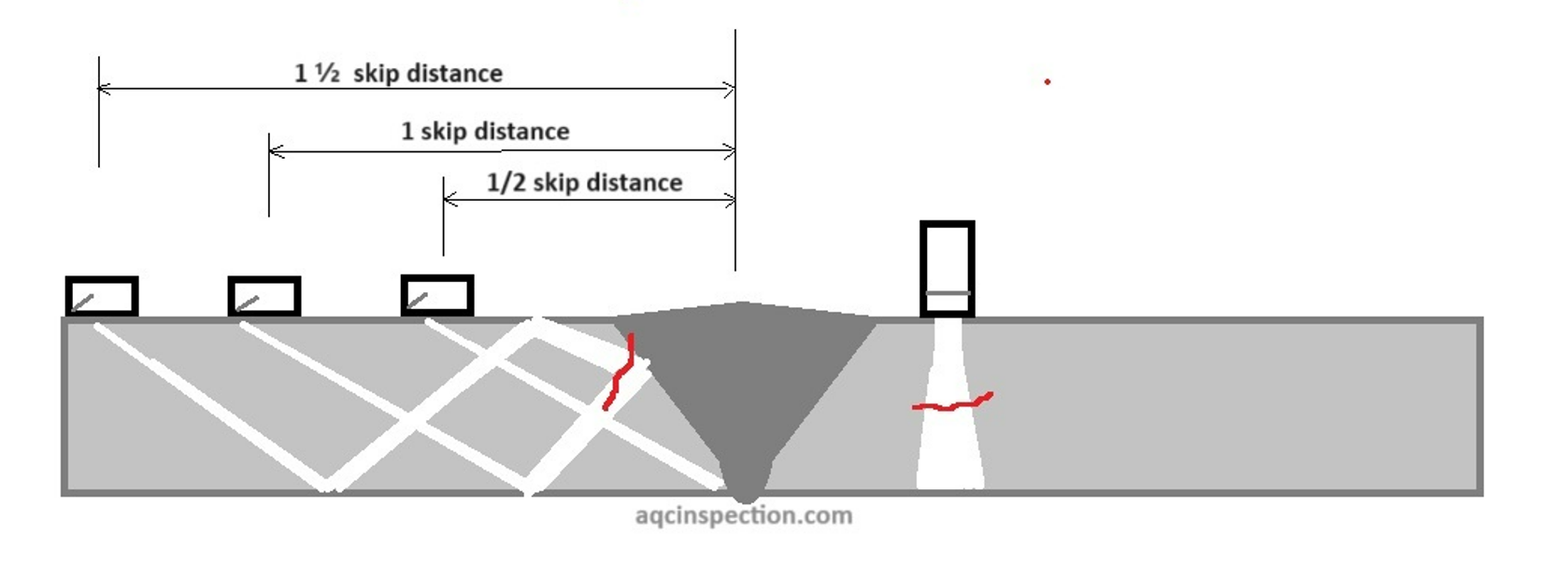

Machine Range Setting :

Range ≥ 3 leg length of the sound paths ,

use the formula below to find out the leg length

![]()

Weld Scanning area on the material :

Should scan at least 1 ½ skip distance on the surface , for complete weld coverage .

Find the formula below to calculate the total weld scan area

![]()

Normal probe selection for Heat affected zone scan:

Use normal probe for thickness more than 80mm

Use TR probe for thickness less than 80mm

Enrollment Now Open!

Enrollment Now Open!

Don’t miss out on this incredible opportunity to boost your career. Enroll now in our NDT course at Advanced Quality Centre AQC and open doors to a brighter future.

Contact Us Today!

Contact Us Today!

@ +91 9489342244 , 8668082413 or email us @[email protected]

visit our website https://aqcinspection.com/

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or

https://ndtcenter.blogspot.com

Subscribe our youtube channel to know more practical explanations https://aqcinspection.com/