Introduction to documents in Welding

Welding Process is almost inevitable in all industry , welding process is involved from foundry cast material repair to airspace components .

Stages of Inspection:

- Project Documents

- Incoming Material Inspection

- Cutting Inspection

- Fit – Up Inspection

- WPS, PQR, WQT & Weld Audits

- Weld Visual Inspection

- Dimensional Inspection

- Non Destructive Testing

- Painting Inspection

- Load Tests / Pressure tests

- Final Inspection

Project Documents

- QAP – Quality Assurance Plan

- ITP – Inspection Test Plan

- Approved drawings

- WPS- Welding Procedure Specification / PQR- Procedure Qualification Records

- WQT- Welder Qualification Test records

- NDT – Non destructive testing procedures

- Consumables control procedure

- Fit up and fabrication procedure

- Painting procedure

- Erection procedure

Incoming Material Inspection

- Visual Inspection

- Dimensional Inspection

- Verification of Heat number and Material Test Certificate

- Preparation of Incoming material inspectioon report

- Sample Chemical and chemical test in Lab / per lot

- Storage

Cutting Inspection

- Dimension inspection as per drawing

- Traceability ( heat number )

- Verification of surface preparation in cutting areas.

Fit-up Inspection

- Verification of traceability

- Dimensional check

- Joint preparation inspection ( root face, bevel angle , root gap etc)

- Ensure proper supports and fixtures are provided to avoid distortion

- Fit-up inspection report

WPS, PQR, WQT & Weld Audit

- Verify appropriate WPS is Available

- Verify the qualification for Welders

- Verify consumables control

- Verify the welding parameters followed as per the WPS

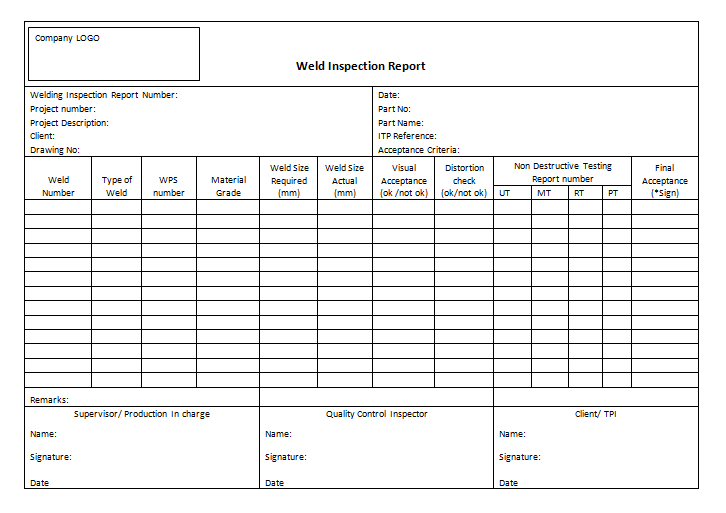

Weld Visual Inspection

- Visual Inspection

- Check the temporary supports are removed

- Write down the welder name and WPS number to each and every weld joint number .Make Visual Inspection Report

Final Dimension Inspection

- Check the dimensions ( Length, width, diagonal, height, flatness, angle , etc )

Non Destructive Test Report

- UT, RT, PT, MT, ET or any other

Load Test or Pressure Test

- Load test / pressure test report or pressure test chart

Painting Inspection

- Surface Preparation & Painting Inspection Report

Final Inspection

- Packing report

- Check list / punch list

- Final QC Dossier .

For more training or certifications for welding operator & training on preparation of documents in welding , please feel free to contact us through [email protected], [email protected], https://aqcinspection.com .

Visit our technical and career updates at our Blog site https://advancedqualitycentre.blogspot.com . or