blogs

blogs

blogs

GTAW Welding on Stainless Steel

GTAW Welding on Stainless steel – SS Produces very strong/tough weld compared to other process Slow process Good appearance Mostly used for Root and hot pass & Low thickness material Low heat input…blogs

SMAW – Shielded Metal Arc Welding on SS Material

Arc welding on SS material : Electrode specification standard : AWS A 5.4 Gas – Not required Example of electrode spec: Austenitic SS : E209, E316, E308, E309, E316, E316L (L – Low Carbon), Martensitic : E410-16 Precipitation hardened : E7Cr-16 Enclosed herewith the Electrode selection chart for…blogs

Welding on Stainless Steel

Stainless Steel They are similar to steel (having Ferrous and carbon) , but chromium content is more than 10.5% thus making it more corrosion resistant What are the types of Stainless Steel ? (based on the grain structure): 1) Ferritic (ex: SS type 409, 430, 442…blogs

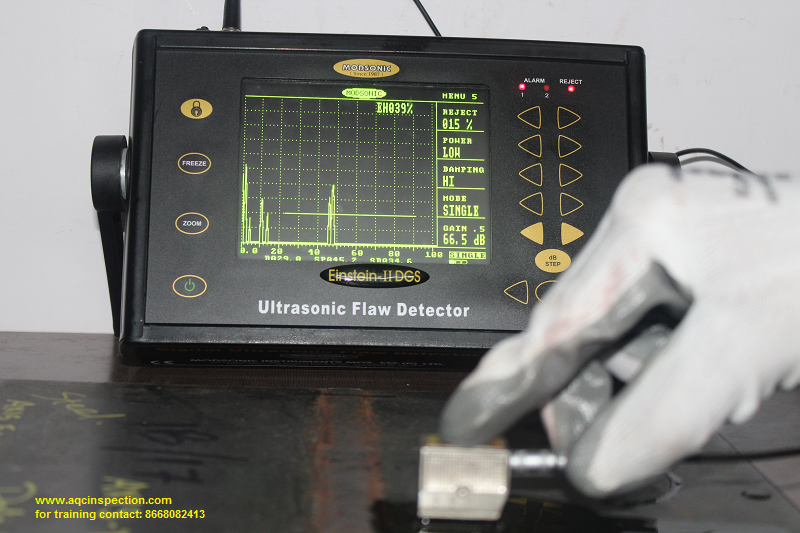

Probe Selection for Ultrasonic Scanning of welds

Ultrasonic testing involves sound waves , that is otherwise called as vibration traveling inside a medium , the ultrasonic sound waves gets reflected back whenever there is change in a material ( different acoustic impedance ) , the reflection is more when the sound…Training

Welder Training at AQC school of Welding Excellance

🔥 Forge Your Future in Welding Excellence! Enroll at AQC School of Welding Excellance Today! 🔥 Are you passionate about welding and ready to turn that passion into a lucrative career? Look no further! 🛠️ Here’s why AQC Welding training school is the gateway to…blogs

What is Brazing ? Where is brazing process used ?

Brazing Process We Advanced Quality Centre, AQC School of Welding Excellence , train Welders , Brazing operators and Soldering applicator in our in house facility and other industrial facility , we train from scratch and make the experts in them. This blog answers the below basic…Recent Projects, Training

Non Destructive testing-Unlock Exciting Career Opportunities

Are you ready to dive into a world of limitless possibilities? Join our Non destructive testing – NDT Course at Advanced Quality Centre and embark on a journey to an exciting career in Non-Destructive Testing! 🌟 Why Choose Us? 🌟 Experienced and Certified Instructors State-of-the-Art…Recent Projects, Training

Forge Mastery at AQC Welding Institute

🌟 Forge Mastery at AQC Welding Institute – Where Precision and Quality Unite! 🌟 🔥 Ignite Your Welding Journey with Unparalleled Expertise! 🔥 Are you ready to weld with precision and elevate your craftsmanship to new heights? Look no further than AQC Welding Institute – where welding…blogs