blogs

blogs

blogs

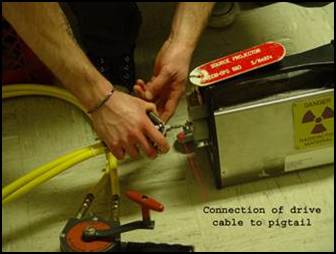

What is Gamma Radiography Testing ?

What is Gamma Radiography Testing? Gamma rays are produced by a radio isotope. A radioisotope has an unstable nuclei that does not have enough binding energy to hold the nucleus together. The spontaneous breakdown of an atomic nucleus resulting in the release of energy…blogs, Job Assistance, Training

Part Time QC courses

What is Quality control? Quality Control (QC) is a department in industries which carries activities of quality inspection, testing and ensures Quality of the product is up to the required standards. But the quality control engineers have various up gradation for attaining high paid jobs by…blogs

Ultrasonic Testing for materials

What is Ultrasonic Testing? ULTRASONIC TESTING is a method for sending ultrasound into material and analyzing the returning sound waves for defect free components. It use scanning devices called probes. After application of Couplant over the material surface probe is place over the material. The sound travels…blogs

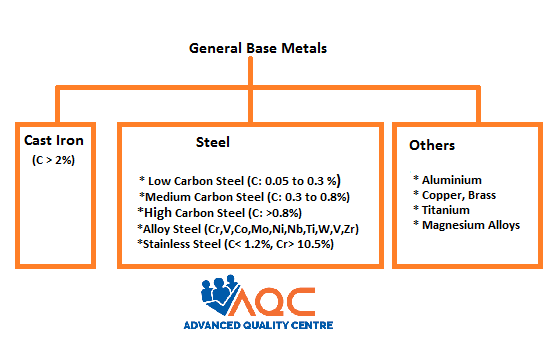

Welding Inspections- All you need to know about Metals

Welding is a process of joining similar metals, i.e. Metals with same base content and similar properties or melting point.There are different types of welding methods based on the process of welding. Generally it involves heating of the metal and fusing them, with or…blogs

What is the Scope of NDT Certification

Scope of NDT Certification The below instructions answers the questions What is NDT ? What is NDT and what is it used for ? Why is NDT Necessary ? When is NDT Necessary ? IS NDT Certifications use Full ? What are certifications in NDT…blogs

What is a Heat Treatment process?

Heat Treatment of metals is the process in which a metal is heated beyond its critical temperature and cooled in a controlled environment to make desirable changes in its internal micro structural properties and chemical properties to obtain a desired structure.blogs

Welding with filler wire procedure

Welding is a process of joining two base metals by heating it. It can be done with or without additional filler metal being used. Below are the few types of welding process : 1)Shield Metal Arc Welding, 2) Metal Inert Gas Welding 3) Tungsten Inert Gas Welding 4) Oxygen…blogs

Inspection test plan – QA QC Course for Mechanical Engineers

QA QC : Quality Control or Quality Assurance is most prioritized department in all industries ranging from Steel Plants to research and development projects. Quality Assurance is the act of streaming the manufacturing process in align with quality requirements Quality Control is the act of checking the…blogs